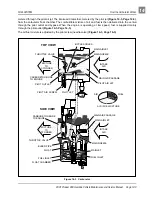

FE350 ENGINE

Crankshaft and Counterbalance

2001 Pioneer 900 Gasoline Vehicle Maintenance and Service Manual Page 13-41

13

BALL BEARING

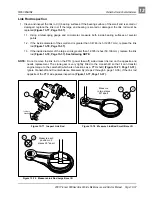

Ball Bearing Removal

1. Remove the oil seal in the crankcase cover. See following NOTE.

NOTE: Never reuse an oil seal. Replace the oil seal with a new one.

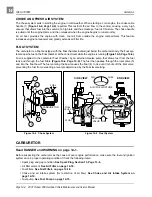

2. Place the crankcase cover (1) on a bench with its outside up (gasket surface against bench) (Figure

3. Using a bearing driver (2) (Part of Club Car Bearing Driver Kit, Part No. 1016416), drive out the ball

bearing (3) as shown.

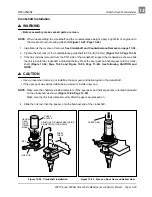

Ball Bearing Inspection

1. Clean the ball bearing thoroughly in high flash-point solvent and dry it.

NOTE: Never use compressed air to dry bearing. Use of compressed air will result in premature bearing

failure.

2. Spin the ball bearing by hand and check for (A) axial play and (B) radial play. Replace the ball bearing

if it is noisy, does not spin smoothly, or if it has any play (Figure 13-90, Page 13-41).

Figure 13-88 Oil Screen Removal

Figure 13-89 Ball Bearing Removal

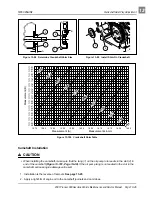

Figure 13-90 Check Ball Bearing

Figure 13-91 Inspect Bearing Surfaces in Crankcase

3

1

2

1

2

3

A

B

3

2

Содержание Pioneer 900

Страница 1: ......

Страница 2: ......

Страница 22: ...3...

Страница 88: ...7...

Страница 92: ...8...

Страница 100: ...9...

Страница 108: ...10...

Страница 188: ...12...

Страница 268: ...14...

Страница 272: ...15...

Страница 316: ...16...

Страница 332: ...17...

Страница 341: ......

Страница 342: ......

Страница 343: ......