FE350 ENGINE

Crankshaft and Counterbalance

Page 13-40 2001 Pioneer 900 Gasoline Vehicle Maintenance and Service Manual

13

Crankshaft Inspection, Continued:

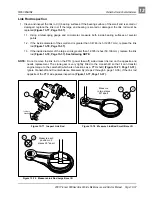

8. Check the crankshaft alignment.

8.1. Place the crankshaft in an alignment jig.

8.2. Turn crankshaft (1) slowly and measure total indicated run-out at the location shown (Figure 13-

8.3. If total run-out exceeds 0.002 inch (0.05 mm), replace the crankshaft.

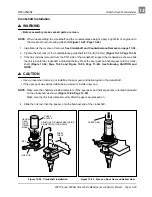

Undersized Connecting Rod

The connecting rod journal can accept an undersized connecting rod with a 1.3779 inches (35.0 mm) inside

diameter. Grinding the crankshaft is required before using the undersized connecting rod.

1. Have a reliable repair shop grind the crankshaft journal (A) (Figure 13-87, Page 13-40).

2. The final finishing dimensions are as follows (Figure 13-87, Page 13-40):

• (A) 1.4759 - 1.4763 inches (37.489 - 37.500 mm)

• (B) 0.110 - 0.126 inch (2.80 - 3.20 mm)

• (C) 1.1968 inches maximum (30.4 mm)

• (D) 1.2775 - 1.2814 inches (32.45 - 32.55 mm)

3. The connecting rod journal (A) must be concentric and cylindrical within 0.0002 inch (0.005 mm) at full

indicator reading (Figure 13-87, Page 13-40).

4. Finish should be very smooth. Use a super fine finishing stone.

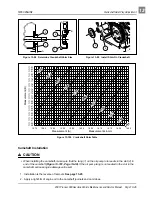

OIL SCREEN

Oil Screen Removal

1. Remove the two bolts (1) to take out the oil screen plate (2) and the oil screen (3) (Figure 13-88, Page 13-41).

2. Clean the oil screen thoroughly with a high flash-point solvent, then dry the screen.

Oil Screen Installation

1. To install the oil screen, reverse the removal procedure.

2. Tighten bolts (1) to 30 in-lb (3.4 N·m).

Figure 13-86 Check Crankshaft Alignment

Figure 13-87 Undersized Connecting Rod Journal

2

1

C

B

A

D

Содержание Pioneer 900

Страница 1: ......

Страница 2: ......

Страница 22: ...3...

Страница 88: ...7...

Страница 92: ...8...

Страница 100: ...9...

Страница 108: ...10...

Страница 188: ...12...

Страница 268: ...14...

Страница 272: ...15...

Страница 316: ...16...

Страница 332: ...17...

Страница 341: ......

Страница 342: ......

Страница 343: ......