FE350 ENGINE

General Information

Page 13-6 2001 Pioneer 900 Gasoline Vehicle Maintenance and Service Manual

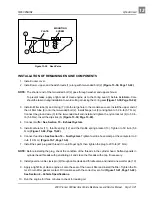

13

Lubrication System, Continued:

The pump draws oil from the sump and forces it under pressure into the crankcase passages as shown (Fig-

ures 13-1 and 13-2, Page 13-5). Oil can build up excess pressure in a lubrication system. To prevent build-

up of excess oil pressure which could possibly force oil past the seals and damage the engine, the pump is

fitted with a pressure relief valve (8) (Figure 13-1, Page 13-5 and Figure 13-3, Page 13-6) that is made of a

ball and a spring. When the pressure increases beyond the pressure of the spring, the ball is forced off its

seat against the spring pressure and excess oil is routed back into the sump (crankcase), thus relieving the

pressure. When the pressure drops below the preset limit, the spring holds the ball against its seat to keep

the oil from draining back into the sump (crankcase).

HYDRAULIC LIFTERS

FE350 engines are equipped with non-adjustable rocker arms (14) and hydraulic lifters (9) (Figure 13-1,

Page 13-5). The purpose of hydraulic lifters is to automatically eliminate all valve clearance in the valve train.

This zero-clearance condition ensures that the valve begins to open at precisely the same time during each

valve event. However, to ensure good seating, there is a small amount of clearance present after the valve

closes. This clearance is eliminated by the lifter before the valve is opened again. The installation of the

hydraulic lifters at the time of engine assembly does not, in most cases, require any special techniques

beyond the normal practice for solid lifter valve trains. There are, however, two areas of concern to be aware

of to assure satisfactory installation and initial engine start. New hydraulic lifters are filled with hydraulic fluid

at the time of installation and they are at their fully extended position. As each rocker arm is tightened into

place, the lifter should be resting on the flat side of the cam lobe (Figure 13-4, Page 13-6). If the camshaft is

not in the correct position, it may be possible to open the valve beyond its normal operating range. This may

cause over-compensation of the valve spring or contact between the valves and the piston.

SPARK PLUG

Spark plugs are selected to suit specific engine design and vehicle operating conditions. The spark plug (CCI

101881101) is designed to give maximum life and efficient combustion of fuel. The spark gap is 0.027 to

0.031 in. (0.69 to 0.79 mm).

Figure 13-3 Cutaway View of Crankcase

Figure 13-4 Cam Position for Lifter Installation

3

8

2

4

4

1

FLAT SIDE

OF CAM

Содержание Pioneer 900

Страница 1: ......

Страница 2: ......

Страница 22: ...3...

Страница 88: ...7...

Страница 92: ...8...

Страница 100: ...9...

Страница 108: ...10...

Страница 188: ...12...

Страница 268: ...14...

Страница 272: ...15...

Страница 316: ...16...

Страница 332: ...17...

Страница 341: ......

Страница 342: ......

Страница 343: ......