1-10

1.2 GENERAL DESCRIPTION

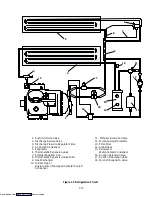

a. Compressor Section

NOTE

Check the compressor Serial/Model Number

plate for CFM displacement, refer to Table 1-2.

The compressor section includes the compressor

(with high pressure switch), optional crankcase heater,

power cable storage compartment, and an optional

transformer (Refer to Table 1-1 and Figure 1-6) which is

located to the left of the compressor.

NOTE

The dual voltage evaporator transformer is

always on line and supplies 460v to the

evaporator motor contactor, and 230v to the

control transformer.

This section also contains the suction modulation

valve, suction solenoid valve, quench expansion valve,

moisture-liquid indicator, manual liquid line valve,

filter-drier, fusible plug or rupture disc, discharge

pressure regulator valve and optional discharge/suction

pressure transducers.

The supply air temperature sensor (STS), supply

recorder sensor (SRS) and ambient sensor (AMBS) are

located at the right side of the compressor.

Table 1-2. Compressor Model Number

Significance Chart

06DR2419CC1970

1st, 2nd & 3rd DIGIT

06D Hermetic Reciprocal

4th DIGIT

R

Refrigeration Duty

6th & 7th DIGIT

DISPLACEMENT

41

41CFM

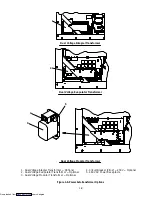

b. Condenser Section

The condensing section consists of a condenser fan

motor, condenser fan and an air-cooled condenser coil.

When the unit is operating, air is pulled in the bottom of

the coil and discharges horizontally out through the front

of the condenser fan grille.

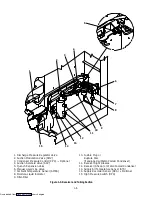

c. Evaporator Section

The evaporator section contains the optional

mechanical temperature recording bulb, return recorder

sensor (RRS), return temperature sensor (RTS),

thermostatic expansion valve, evaporator fan motors and

fans (2), evaporator coil and heaters, drain pan and

heater, defrost termination sensor, heat termination

switch, and a heat exchanger. See Figure 1-2 and

Figure 1-3 for sensor location.

The evaporator fans circulate air throughout the

container by pulling air in the top of the refrigeration unit

and directing the air through the evaporator coil where it

is either heated or cooled, and then discharged out the

bottom of the refrigeration unit into the container.

Some units are equipped with two-speed evaporator

fan motors. Refer to Table 1-1. When transporting

perishable (chilled) commodities, the fan motors will

normally be in high speed above ---10

_

C (+14

_

F) or

---5

_

C (+23

_

F) optionally. If the unit is equipped with

economy mode and it is turned on, the fan motors will run

in low speed.

The evaporator coil heaters are accessible by

removing the front, lower access panel. The defrost

termination sensor (DTS) is located on the coil center

tube-sheet and may be serviced by removing the upper

rear, panel or by removing the left front, upper access

panel and reaching through the evaporator fan venturi

AFTER POWER IS TURNED OFF AND POWER

PLUG DISCONNECTED.

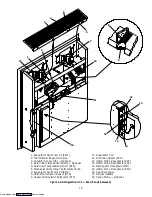

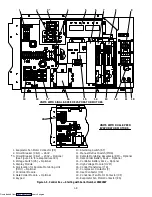

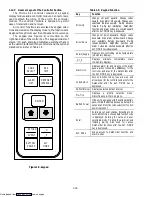

d. Control Box

The control box includes the manual switches, circuit

breaker(s), contactors, transformers, fuses, keypad,

display module, high voltage module, controller module

and an optional DataCorder module. (See Figure 1-4 or

Figure 1-5).

1.3 REFRIGERATION SYSTEM DATA

a. Compressor --- Motor Assembly

No. of Cylinders:

6

Model:

06DR

Weight (Dry):

260 lb (118 kg)

b. Approved Compressor Oil

Castrol Icematic --- SW20

c. Compressor Oil Charge

3.6 liters (7.6 U.S. pints)

d. Compressor Oil Sight Glass

The oil level range should be between the bottom to

1/8 of the sight glass, with the compressor off.

e. Expansion Valve Superheat

Verify at ---18

_

C (0

_

F) container box temperature:

3.36 to 4.48

_

C (6 to 8

_

F)

f. Heater Termination Thermostat

Opens:

54 (

¦

3)

_

C = 130 (

¦

5)

_

F

Closes:

38 (

¦

4)

_

C = 100 (

¦

7)

_

F

g. High Pressure Switch

Cutout:

25 (

¦

0.7) kg/cm

@

= 350 (

¦

10) psig

Cut-In:

18 (

¦

0.7) kg/cm

@

= 250 (

¦

10) psig

h. Refrigeration Charge

Refer to Table 1-1.

i. Fusible Plug

Melting point:

93

_

C = (200

_

F)

j. Rupture Disc (Used on water-cooled units only)

Bursts at:

35 ±5% kg/cm

@

= (500 ±5% psig)

k. Unit Weight

Refer to Table 1-1.

Downloaded from

Содержание 69NT40-489

Страница 1: ...Model 69NT40 489 T 259 Rev F Downloaded from ManualsNet com search engine ...

Страница 100: ...5 9 Figure 5 4 Electrical Wiring Diagram Model 69NT40 489 2 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...

Страница 141: ...5 50 Figure 5 25 Electrical Schematic Model 69NT40 489 19 Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

Страница 142: ...5 51 Figure 5 25 Electrical Schematic Model 69NT40 489 19 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...

Страница 149: ...5 58 Figure 5 29 Electrical Schematic Models 69NT40 489 50 Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

Страница 150: ...5 59 Figure 5 29 Electrical Schematic Models 69NT40 489 50 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...

Страница 157: ...5 66 Figure 5 33 Electrical Schematic Models 69NT40 489 62 Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

Страница 158: ...5 67 Figure 5 33 Electrical Schematic Models 69NT40 489 62 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...

Страница 161: ...5 70 Figure 5 35 Electrical Schematic Models 69NT40 489 78 Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

Страница 162: ...5 71 Figure 5 35 Electrical Schematic Models 69NT40 489 78 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...

Страница 165: ...5 74 Figure 5 37 Electrical Schematic Models 69NT40 489 80 Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

Страница 166: ...5 75 Figure 5 37 Electrical Schematic Models 69NT40 489 80 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...

Страница 169: ...5 78 Figure 5 39 Electrical Schematic Models 69NT40 489 30 31 Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

Страница 170: ...5 79 Figure 5 39 Electrical Schematic Models 69NT40 489 30 31 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...