1-27

Alarm 63 --- Current Over Limit

Alarm 63 is triggered within the current limiting

system. If the compressor is ON and current limiting

procedures cannot maintain a current level below the

user selected limit, the current limit alarm is activated.

This alarm is a display alarm and is inactivated by

power cycling the unit, changing the current limit via the

code select Cd32, or if the SMV is allowed to open to

100% and the suction solenoid valve is allowed to open.

Alarm 64 --- Discharge Temperature Over Limit

Alarm 64 is triggered if the discharge temperature is

sensed greater than 154

_

C (310

_

F) for 3 continuous

minutes, or if it exceeds 177

_

C (350

_

F), or if the sensor is

out of range. This is a display alarm and has no associated

failure action.

Alarm 65 --- Discharge Pressure or Condenser

Pressure (CPC) Sensor Failure

Alarm 65 is triggered by a compressor discharge or

condenser pressure sensor reading outside the valid

range of 73.20 cm Hg (30 in Hg) to 32.34 Kg/cm

2

(460

psig). This is a display alarm and has no associated failure

action.

Alarm 66 --- Suction Pressure Sensor Failure

Alarm 66 is triggered by a suction pressure sensor

reading outside the valid range of 73.20 cm Hg (30 in Hg)

to 32.34 Kg/cm

2

(460 psig). This is a display alarm and has

no associated failure action.

Alarm 67 --- Humidity Sensor Failure

Alarm 67 is triggered by a humidity sensor reading

outside the valid range of 0% to 100% relative humidity.

If alarm 67 is active and the dehumidification mode

was previously activated, then it will be deactivated.

ERR # - Internal Microprocessor Failure

The controller performs self-check routines. if an

internal (electronic) failure occurs, an ERR #0---5 will

appear on the display. This is an indication the controller

needs to be replaced.

Entr stpt - Enter Setpoint (Press Arrow & Enter)

The Controller is prompting the operator to enter a

set point.

LO -

Low Mains Voltage (Change of function codes

Cd27-Cd33 disabled and no alarm stored.)

This message will be alternately displayed with the

set point whenever the mains voltage is less than 75% of

its proper voltage.

VENT

This message will be alternately displayed with the

set point whenever the CTD Controlled Atmosphere

(CA) option is in the VENT mode.

P-CA

This message will be alternately displayed with the

set point whenever the CTD Controlled Atmosphere

(CA) option is in the Pre-Trip mode.

NOTE

The left display of the Refrigeration Controller

will alternately display P-CA and set point for

units with the CTD Controlled Atmosphere

(CA) option (refer to Table 1-1).

1.13 PRE-TRIP DIAGNOSTICS

NOTE

The Refrigeration Controller will be locked-out

of Pre-Trip if the CTD Controlled Atmosphere

(CA) option (refer to Table 1-1) is in either the

Vent or Pre-Trip mode.

CAUTION

Pre-trip inspection should not be performed

with critical temperature cargoes in the

container.

Pre-trip Diagnostics is an independent mode which

will suspend the normal Control Mode activities when

initiated by the user. With pre-trip diagnostics, either all

the pre-trip tests can be executed in a defined sequence

(Auto Mode), or one of the pre-trip tests can be selected

to be executed (Manual Mode), based on the sequence of

key selections made.

a. Starting and Terminating Pre-Trip

A Pre-trip selection menu is displayed by pressing the

PRE-TRIP key. This places the user into a test selection

menu. If no selection is made, the pre-trip menu selection

process will terminate automatically. Pre-Trip will termi-

nate if the VENT mode is selected on the CA Controller.

The user must scroll through the selection by pressing the

UP ARROW or DOWN ARROW keys, then pressing

the ENTER key when the selection is made. While the

tests are being executed, the user can terminate the

pre-trip mode by holding the PRE-TRIP key. The unit

will then resume normal operation. If the user decides to

terminate a test but remain at the test selection menu, the

user may press the UP ARROW key. When this is done

all machinery outputs will be de-energized and the test

selection menu will be displayed.

The pre-trip diagnostics may also be initiated via

communication, but when initiated will always attempt to

execute the entire battery of tests (auto mode).

b. Current Limiting During Pre-Trip

Throughout the duration of any pre-trip mode, the

Current Limit processing is active.

NOTE

When current limiting is initiated, the

compressor is immediately cycled through a

reliability enhancement algorithm (SMV is

cycled between 70% to 0%), to remove any

refrigerant trapped in the oil of the compressor.

This also happens during Pre-Trip tests P6-0 and

P6-4. For current limiting and P6-0 the algorithm

is 10 cycles long, and for P6-4 its 5 cycles long.

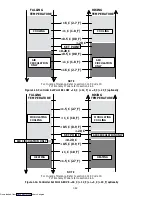

c. Test Codes

A detailed description of the pre-trip test codes is

listed in the following section, however, for a quick

reference list refer to Table 1-8.

Downloaded from

Содержание 69NT40-489

Страница 1: ...Model 69NT40 489 T 259 Rev F Downloaded from ManualsNet com search engine ...

Страница 100: ...5 9 Figure 5 4 Electrical Wiring Diagram Model 69NT40 489 2 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...

Страница 141: ...5 50 Figure 5 25 Electrical Schematic Model 69NT40 489 19 Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

Страница 142: ...5 51 Figure 5 25 Electrical Schematic Model 69NT40 489 19 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...

Страница 149: ...5 58 Figure 5 29 Electrical Schematic Models 69NT40 489 50 Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

Страница 150: ...5 59 Figure 5 29 Electrical Schematic Models 69NT40 489 50 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...

Страница 157: ...5 66 Figure 5 33 Electrical Schematic Models 69NT40 489 62 Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

Страница 158: ...5 67 Figure 5 33 Electrical Schematic Models 69NT40 489 62 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...

Страница 161: ...5 70 Figure 5 35 Electrical Schematic Models 69NT40 489 78 Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

Страница 162: ...5 71 Figure 5 35 Electrical Schematic Models 69NT40 489 78 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...

Страница 165: ...5 74 Figure 5 37 Electrical Schematic Models 69NT40 489 80 Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

Страница 166: ...5 75 Figure 5 37 Electrical Schematic Models 69NT40 489 80 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...

Страница 169: ...5 78 Figure 5 39 Electrical Schematic Models 69NT40 489 30 31 Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

Страница 170: ...5 79 Figure 5 39 Electrical Schematic Models 69NT40 489 30 31 Sheet 2 of 2 Downloaded from ManualsNet com search engine ...