5.3 Tapping Operation

5-17

Spindle Axis

Operation

5.3.2

Spindle Axis Servo Drive-based Position Loop Tapping

To switch to a position loop and perform tapping, Servo Mode must be set to provide a constant excitation cur-

rent to maintain the speed linearity.

Set SVCMD_IO.SV_MOD to 1 in the VELCTRL or INTERPOLATE command.

When SV_MOD is set, 200 to 300 ms of delay is required to establish 100% of the required excitation current.

(Allocate this time with a timer on the host controller.)

Be careful, because any position references that are sent during this time will not function correctly and cause

vibration.

Additional Information

• Servo Mode establishes and maintains feed linearity and continuously provides excitation current, even

when the axis is stopped.

This preserves control loop response and increases constraint when the axis is stopped in the same way as a

servo.

• If SV_MOD is turned OFF, the excitation current is not supplied when the axis is stopped.

Also, the constraint when the axis is stopped is reduced.

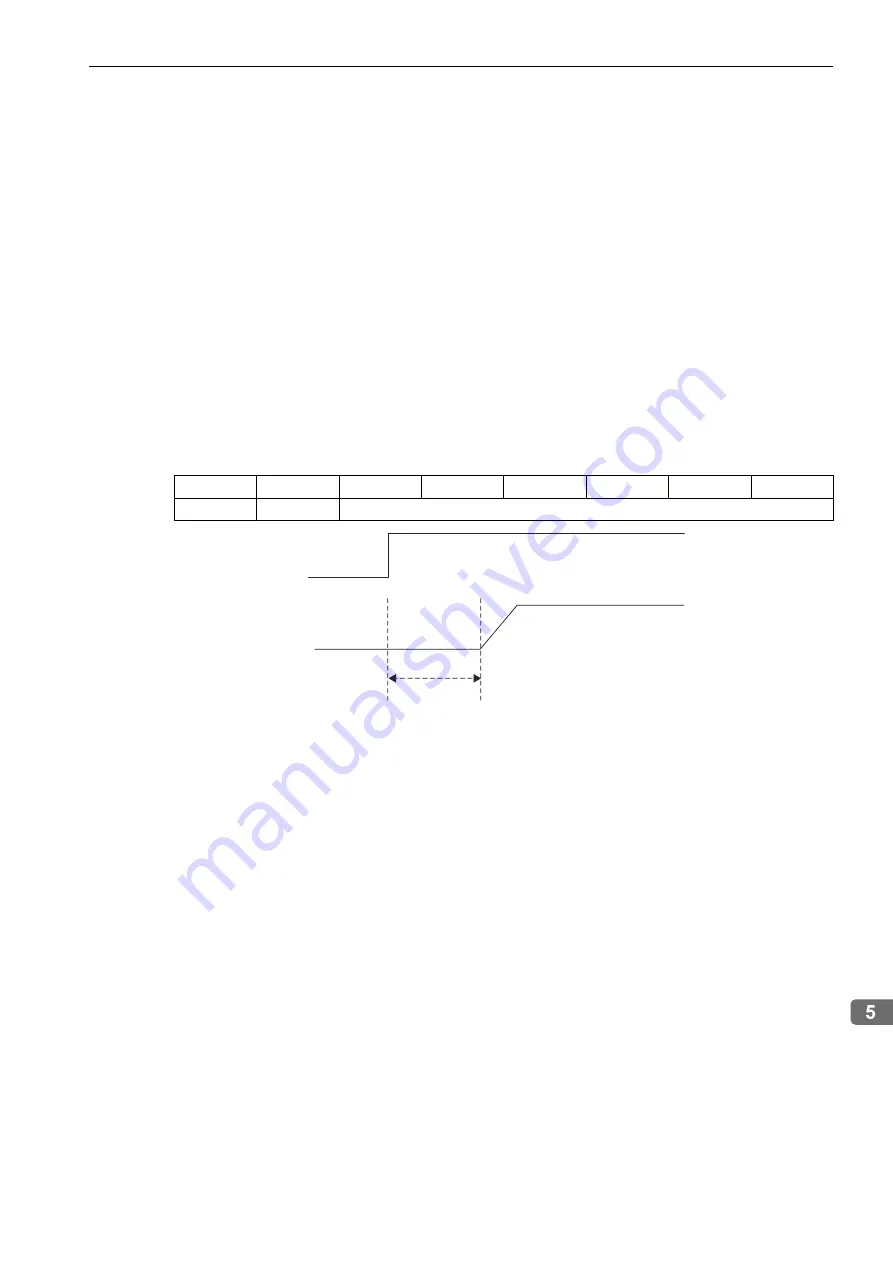

The following figure shows the relationship between Servo Mode and the INTERPOLATE command.

SVCMD_IO.SV_MOD

Therefore, the INTERPOLATE command can be executed 200 to 300 ms after the mode is changed to Servo

Mode for tapping and other spindle axis feeding operations.

If tapping is continued, SV_MOD will not turn ON or OFF, producing a constant reference.

For a position loop for a spindle axis, you can send the MECHATROLINK-III INTERPOLATE command to

smoothly change from speed control to position loop control as long as Servo Mode is set and the constant

torque range is not exceeded.

Bit 31

Bit 30

Bit 29

Bit 28

Bit 27

Bit 26

Bit 25

Bit 24

WND_CHG

SV_MOD

Reserved.

200 to 300 ms

SVCMD_IO.SV_MOD

INTERPOLATE