5 Spindle Axis Operation

5.3.6 Tapping Applications

5-22

5.3.6

Tapping Applications

(1) Feed Hold Tap Return

If feed hold resistance is encountered during tapping, the tap may break off if the axis continues on without

stopping. To prevent this, decelerate the axis to a stop and return the axis in the opposite direction.

For the reversal, use interpolation to maintain the shape of the tap and stop the axis after execution of the

return operation has been completed.

(2) Specified Speed Return during Tapping

For large-diameter tapping, there is a difference in the cutting torque between the forward and return passes,

so the return spindle axis speed can be set to increase to a specified speed. The return interpolation speed is

also increased for the return operation.

However, speed is controlled so that the torque is not saturated.

(3) Deep Hole Tapping

During tapping, the tap can be repeatedly returned to remove any cutting chips and inserted again to tap deeper

in order to cut deep hole taps.

(4) Maximum Speed, Acceleration Time, and Acceleration/Deceleration of Tapping

Spindle Axes

The acceleration rate in position control (without torque saturation) must be sufficient enough to maintain lin-

earity.

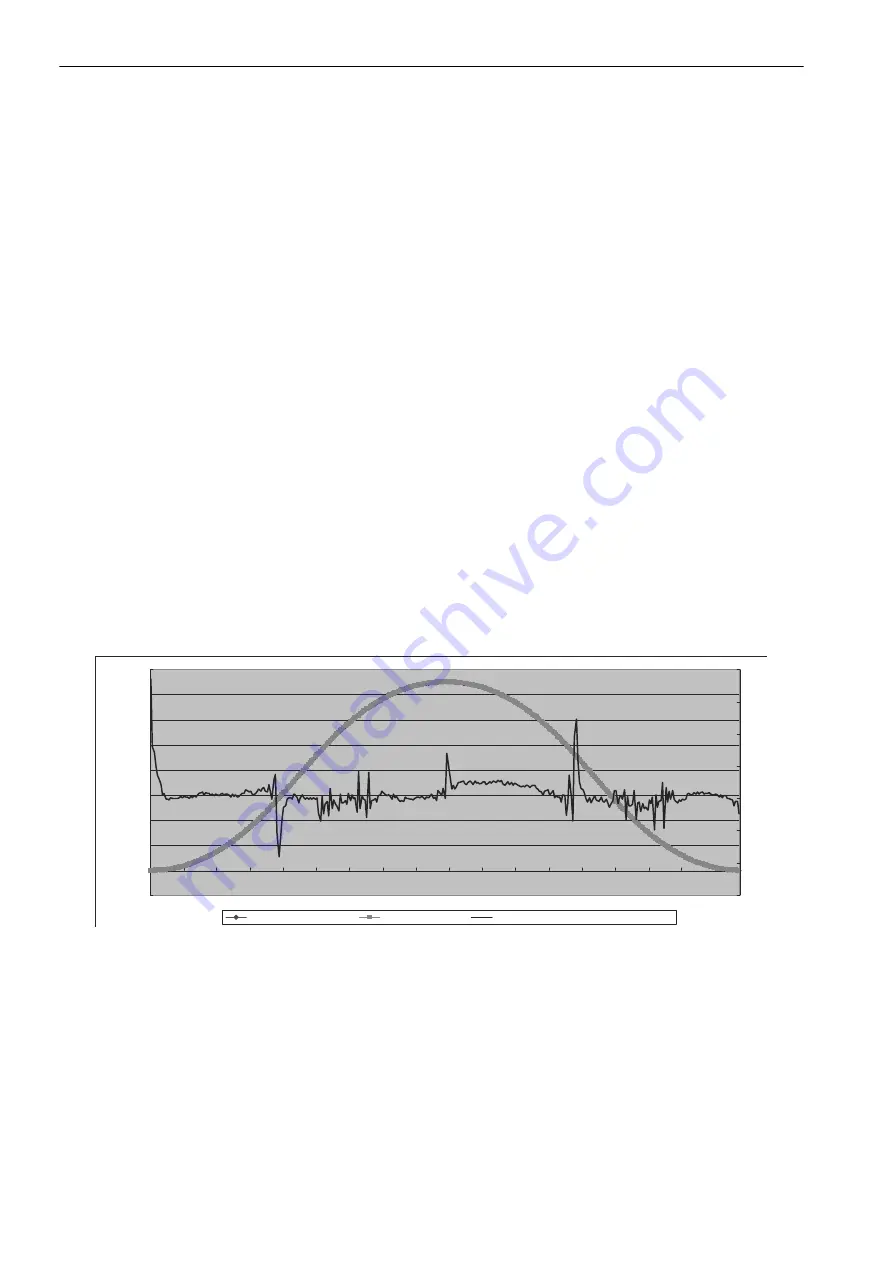

(5) Spindle Axis-based Feed Axis Synchronization Error Indicator for Tapping

To adjust and calibrate tapping properly, you must have some way to check the synchronization error of the

feed axis using the spindle axis as a base.

To achieve this, you need to develop an error indicator as shown below.

You must trace the difference between the positive value APOS

zs

of the tap position and the APOS feedback

position of the tap in regards to the APOS

s

revolution position of the spindle axis, then perform any adjust-

ments that are required to keep the synchronization error within the accuracy of the tap.

-20000000

0

20000000

40000000

60000000

80000000

100000000

120000000

140000000

160000000

1

21

41

61

81

101

121

141

161

181

201

221

241

261

281

301

321

341

-6

-4

-2

0

2

4

6

8

Synchronization error (0.001 mm) (mm*10

-3

)

Z axis FB (mm*10

-6

)

Spindle axis FB (rev*10

-6

)