2.4 Operation Sequence

2-7

MECHA

TROLINK-

III

Communications

2.4

Operation Sequence

The operation sequence is the procedure for operating the servo drive through commands sent from the host

controller.

When cyclic communications start, the operation sequence is executed to operate the machine.

The operation sequence depends on whether the SERVOPACK parameters are managed by the host controller

or by the SERVOPACK.

Refer to

5.1 Operation Sequence for Managing Parameters Using a Controller

and

5.2 Operation Sequence

for Managing Parameters Using a SERVOPACK

in the

Σ

-V-SD Series User’s Manual MECHATROLINK-III

Standard Servo Profile Commands

(Manual No.: SIEP S800000 76) for details on operation sequences.

2.4.1

Operation Sequence When Parameters Are Managed by the Host Controller

Parameters are transferred to the SERVOPACK from the host controller after the power supply is turned ON.

Therefore, if parameters are changed at the host controller or if the SERVOPACK is replaced, the parameters

do not need to be set again.

The operation sequence when parameters are managed by the host controller is given below.

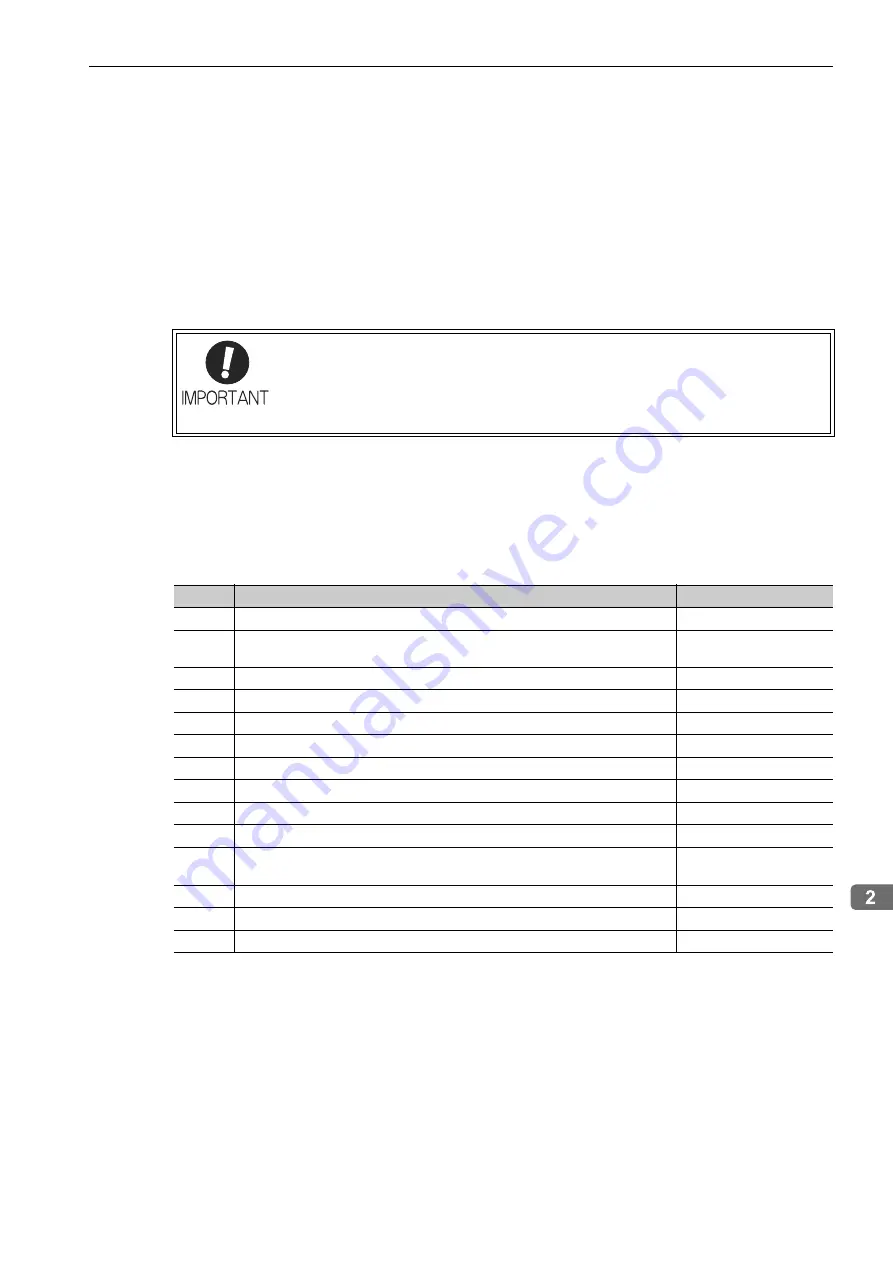

Note: If the communications connection is disconnected properly, step 3 is not required.

If the communications connection is not disconnected properly, send the DISCONNECT command for at least two

communications cycles before you establish a connection again, and then send the CONNECT command in step 4.

A motor parameter file must be written to the SERVOPACK for the spindle motor, but with

the following operation sequence, the motor parameter file is not written.

To write the motor parameter file, use either the SigmaWin for

Σ

-V-SD (MT) or the drive

parameter upload/download function (refer to

8.2 SERVOPACK Parameter Uploading/

Downloading Functions

.

Step

Operation

Commands Used

1

Turn ON the control and main circuit power supplies.

–

2

Confirm that the SERVOPACK initialization has been completed (i.e., confirm

that SVCMD_STAT.M_RDY = 1).

NOP

3

Disconnect the previous communications connection.

DISCONNECT

4

Establish a communications connection and start counting WDT.

CONNECT

5

Read the device ID and other information.

ID_RD or MEM_RD

6

Read the device settings (e.g., parameters).

SVPRM_RD

7

Set the parameters required for the device.

SVPRM_WR

8

Enable the parameters that were set (setup).

CONFIG

9

Turn ON the power supply to the encoder and obtain the position data.

SENS_ON

10

Turn ON the servo.

SV_ON

11

Start operation.

INTERPOLATE,

VELCTRL, etc.

12

Turn OFF the servo.

SV_OFF

13

Disconnect communications.

DISCONNECT

14

Turn OFF the control and main circuit power supplies.

–