9 Monitoring

9-12

9.4

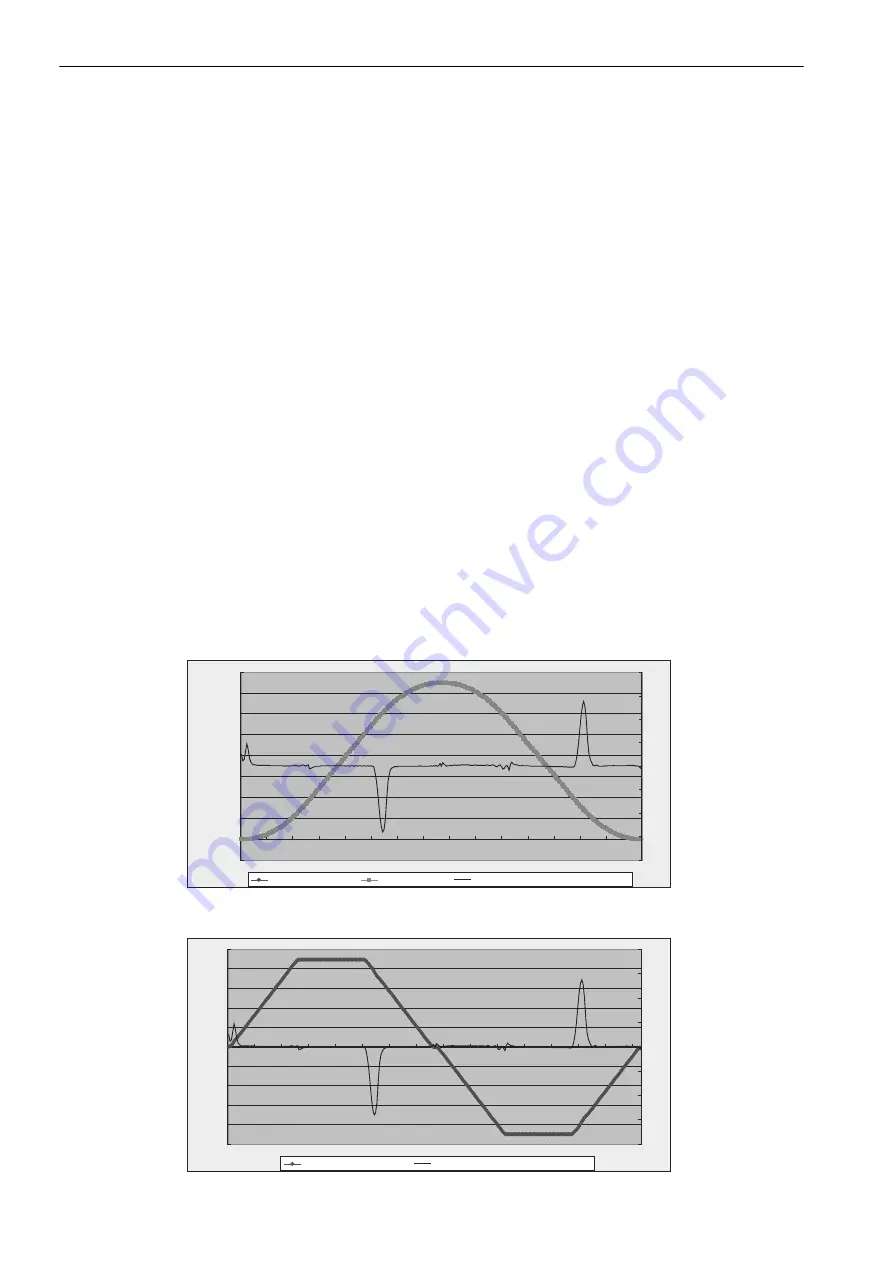

Tapping Synchronization Accuracy Drawings

Tapping operations synchronize the operation of the spindle axis and feed axis (Z axis, etc.) to cut screw holes

in workpieces. This requires the confirmation of the synchronization accuracy of the spindle and feed axes.

The reference positions (CPOS) and coordinate positions (APOS) of the spindle and feed axes are used to

draw the reference and position, position error, and motor speed.

To determine the tapping synchronization error, you must check for the area where the synchronization error is

the greatest during the tapping operation.

A function to draw the tapping synchronization accuracy requires the following capabilities:

• Selection of the axes for which to perform the drawing (spindle and feed axes)

• Screw pitch (screw lead) setting for the tapping operation

*1

• Data acquisition cycle setting

*2

(sampling cycle and number of sampling points setting)

• Path data acquisition trigger setting

*3

• Drawing the tapping synchronization error

*4

• Synchronization error measurement and display of the greatest value

• Ability to save and load measured path data

• Overlay comparison of measured path data (i.e., the ability to load past data and overlay them on the current

data)

*5

∗1.

The host controller can automatically obtain the screw pitch with a G-code command.

∗2.

This depends on the data storage memory area of the host controller.

∗3.

A sequence that automatically activates a trigger to start data acquisition when the spindle axis or the feed axis begins

acceleration is recommended.

∗4.

Plot the synchronization error between the spindle and feed axes in

μ

m. Plot the spindle axis position and spindle

axis motor speed together to determine where the margin of error is greatest during the tapping operation.

∗5.

Read the past data and overlay it on top of the current data.

Refer to the following drawing of the tapping synchronization accuracy as a reference.

• Spindle Axis/Z Axis Positions and Tapping Synchronization Error

• Spindle Axis Motor Speed and Tapping Synchronization Error

-20,000,000

0

20,000,000

40,000,000

60,000,000

80,000,000

100,000,000

120,000,000

140,000,000

160,000,000

1

21

41

61

81

101

121

141

161

181

201

221

241

261

281

301

-80

-60

-40

-20

0

20

40

60

80

Synchronization error (0.001 mm) (mm*10

-3

)

Z axis FB (mm*10

-6

)

Spindle axis FB (rev*10

-6

)

-5,000

-4,000

-3,000

-2,000

-1,000

0

1,000

2,000

3,000

4,000

5,000

1

21

41

61

81

101

121

141

161

181

201

221

241

261

281

301

-80

-60

-40

-20

0

20

40

60

80

Synchronization error (0.001 mm) (mm*10

-3

)

Spindle axis FB speed [min

-1

]