4 Feed Axis Operation

4.1.3 Gain Selection (G-SEL)

4-8

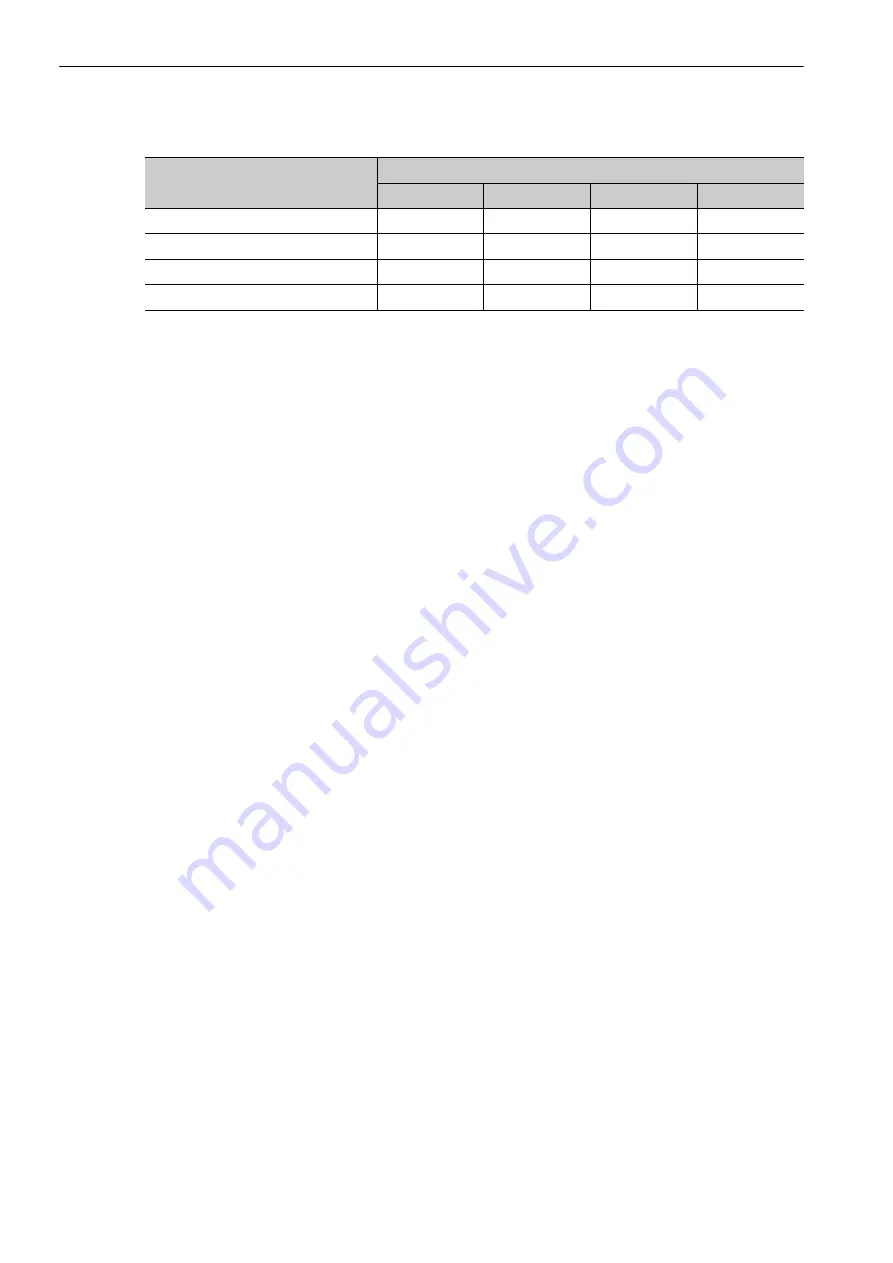

Gain Bank and Parameter Combinations

The gain parameters are selected based on the feed axis operation that is used (interpolation, high-speed feed-

ing, tap, etc.). Adjust the gain based on the feed axis operation that is used.

Example

• Cutting Operation

For cutting operations, set SVCMD_IO.G-SEL to 0 ((bit 11, bit 10, bit 9, bit 8) = (0, 0, 0, 0)) to select gain

bank 0.

Set Pn070.0 to 1 to enable predictive control. Set Pn070.1 to 1 to enable quadrant projection compensation.

• High-speed Feeding Operation

For high-speed feeding operations, set SVCMD_IO.G-SEL to 5 ((bit 11, bit 10, bit 9, bit 8) = (0, 1, 0, 1)) to

select gain bank 1.

Set Pn071.0 to 1 to enable internal speed feedforward. Set Pn071.0 to 2 to enable model following control.

• Spindle Axis Operation

For spindle axis operations, set SVCMD_IO.G-SEL to 10 ((bit 11, bit 10, bit 9, bit 8) = (1, 0, 1, 0)) to select

gain bank 2.

Synchronized Operation of Feed and Spindle Axes

In operations such as tapping, where the feed and spindle axes must be synchronized, you must match the

position loop gain for each of the axes. Failure to do so will result in increased synchronization error, which

will affect the operation.

If the gains for cutting operations (gain bank 0) are too large, you may not be able to set the same gains for the

spindle axis (doing so may result in vibration, for example). Design the system so gain bank 2 or 3 can be

selected for the feeding axis motion that needs to be synchronized with the spindle axis.

Gain Parameter

Gain Bank

0

1

2

3

Speed loop gain

Pn100

Pn104

Pn12B

Pn12E

Speed loop integral time constant

Pn101

Pn105

Pn12C

Pn12F

Position loop gain

Pn102

Pn106

Pn12D

Pn130

Torque reference filter

Pn401

Pn412

Pn413

Pn414