Page 84

WESMAR

HD800

~

Motor not mounted vertically with

reservoir toward bottom

~

Obstruction in the seachest

~

Allen screw on hydraulic reservoir

has

not

been replaced with

thumb

screw, thereby

creating a vacuum

in the

reservoir

20.2 “Raise” and “Lower” are reversed:

~ Solenoid valve miswired to hoist board

~ The two hydraulic hoses need to be reversed

20.3

Motor continues to run after raising

or lowering:

~

Limit switches not connected, or not

connected properly to the hoist board

~

Broken wires to limit switches

~

Limit switches on hoist rack not

properly aligned and are not triggering when the

top

hoist clamp approaches

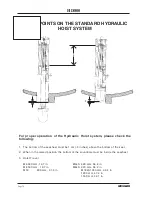

20.4 Soundome will not stay up:

~

Dirty check valves

~

Check for leak in the hydraulic cylinder.

21.0 RESERVOIR

OIL

MAINTENANCE

The hydraulic system is fi lled with oil before shipment, and

should not require any more for proper operation.

Check the oil level after installation, and once a month after

that, by removing the venting plug on the side of the reservoir.

Fluid level should be just below the opening.

For your HD800 AC or DC hydraulic hoist system, use

Chevron Automatic Transmission Fluid, “Dexron II,” or

its equivalent.

21.1 Filling the Oil Reservoir

Summary of Contents for HD800/110-10

Page 10: ...Page 10 WESMAR HD800...

Page 32: ...Page 32 WESMAR HD800 Section III INSTALLATION...

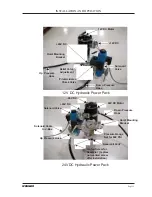

Page 64: ...Page 64 WESMAR HD800 HYDRAULIC HOIST ASSEMBLY A...

Page 65: ...Page 65 WESMAR INSTALLATION AND OPERATION HYDRAULIC HOIST ASSEMBLY B...

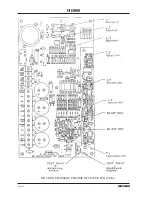

Page 74: ...Page 74 WESMAR HD800 M18 HOIST CONTROL CIRCUITRY THIS PAGE LEFT INTENTIONALLY BLANK...

Page 86: ...Page 86 WESMAR HD800...

Page 87: ...Page 87 WESMAR INSTALLATION AND OPERATION Section IV FIELD ADJUSTMENTS CALIBRATION...

Page 92: ...Page 92 WESMAR HD800 HD J BOX TRANSMIT PREAMP RECEIVER PCB T P R...