Page 49

WESMAR

INSTALLATION AND OPERATION

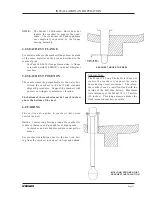

position with the top hoist clamp even with the top

of the lead screw.]

Loosen the packing gland, safety clamp, and top hoist

clamp.

Feed the soundome cable and tube through them in

the same order.

If the top hoist clamp will not fit around the soun-

dome tube, increase the diameter of the hole in

the top hoist clamp. Do this by pressing a wedge

into the slot between the hole for the soundome

tube and the hole for the lead screw. DO NOT

remove the top hoist clamp from the lead screw.

Tighten the top hoist clamp.

Place the safety clamp immediately below the hoist

clamp and fasten it with the locking bolt.

We discuss positioning the tube in 4.0 Positioning

the Soundome.

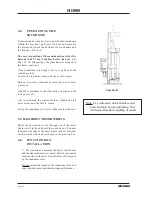

Place the neoprene gasket on the seachest flange.

Lower the soundome into the seachest.

Position the hoist assembly so that you can easily

reach the Junction Box.

Use the bolts provided to secure the hoist flange to

the seachest.

4.0

POSITIONING THE

SOUNDOME

To determine how high or low to position the soundome

within the seachest, go below the boat and measure

the distance between the bottom of the soundome and

the end of the seachest.

The correct position of the soundome boot is

3.8

cm (1.5 inches) within the seachest.

See Page

55, #1.

If the soundome is too high or too low loosen the top

hoist clamp and safety clamp.

Raise or lower the soundome according to your mea-

surement.

Align the soundome so that the mark you made on the

Special Note:

If you must remove the top hoist clamp from

the lead screw to insert the tube, follow

these steps:

1. Remove the bronze shear pin from the

base of the lead screw.

2. Remove both top hoist clamp and lead

screw from the motor shaft.

3. When you replace the top hoist clamp

and lead screw, be sure they are in the

same position as before.

4. Tighten the locking bolts on the top hoist

clamp until they dig into the plastic.

When the hoist is in the "Up" position,

the lead screw should be even with the

top of the hoist clamp.

TOP HOIST CLAMP

NOTE: ..............................................................

Use anti-seize on all stainless steel bolts

and nuts before tightening. This will

reduce the affect of galling or seizure.

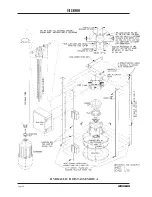

Summary of Contents for HD800/110-10

Page 10: ...Page 10 WESMAR HD800...

Page 32: ...Page 32 WESMAR HD800 Section III INSTALLATION...

Page 64: ...Page 64 WESMAR HD800 HYDRAULIC HOIST ASSEMBLY A...

Page 65: ...Page 65 WESMAR INSTALLATION AND OPERATION HYDRAULIC HOIST ASSEMBLY B...

Page 74: ...Page 74 WESMAR HD800 M18 HOIST CONTROL CIRCUITRY THIS PAGE LEFT INTENTIONALLY BLANK...

Page 86: ...Page 86 WESMAR HD800...

Page 87: ...Page 87 WESMAR INSTALLATION AND OPERATION Section IV FIELD ADJUSTMENTS CALIBRATION...

Page 92: ...Page 92 WESMAR HD800 HD J BOX TRANSMIT PREAMP RECEIVER PCB T P R...