A fault message is displayed and output "Motor fault" is enabled if there is an

overload fault.

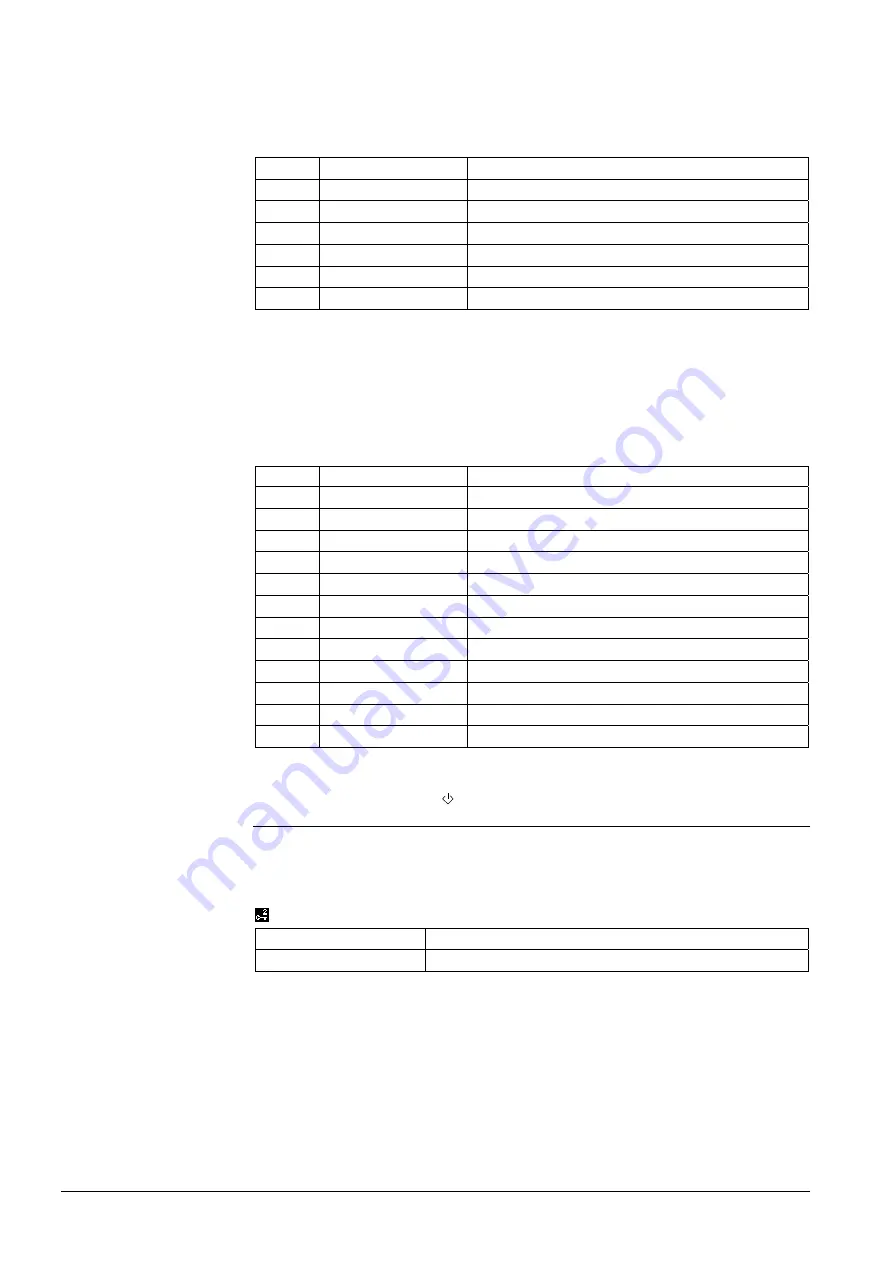

You can change the following texts ex-works texts in the RMS705B at the

password level.

No.

Text

Effect with factory setting

1311

[Motor 1] overload

Urgent message; must be acknowledged.

1321

[Motor 2] overload

Urgent message; must be acknowledged.

1331

[Motor 3] overload

Urgent message; must be acknowledged.

1341

[Motor 4] overload

Urgent message; must be acknowledged.

1351

[Motor 5] overload

Urgent message; must be acknowledged.

1361

[Motor 6] overload

Urgent message; must be acknowledged.

Overload messages

1

or

2-speed motor

If only one pump is faulty during twin motor operation, run priority changes to the

non-faulty motor output. The fault acknowledgement setting has no effect on

changeover. The corresponding overload signal is issued. If both motors are faulty,

a fault message is displayed as per Section "8.4.4".

Overload messages

twin motor

You can change the following texts ex-works texts in the RMS705B at the

password level.

No.

Text

Effect with factory setting

1314

[Motor 1A] overload Non-urgent message; must be acknowledged.

1315

[Motor 1B] overload Non-urgent message; must be acknowledged.

1324

[Motor 2A] overload Non-urgent message; must be acknowledged.

1325

[Motor 2B] overload Non-urgent message; must be acknowledged.

1334

[Motor 3A] overload Non-urgent message; must be acknowledged.

1335

[Motor 3B] overload Non-urgent message; must be acknowledged.

1344

[Motor 4A] overload Non-urgent message; must be acknowledged.

1345

[Motor 4B] overload Non-urgent message; must be acknowledged.

1354

[Motor 5A] overload Non-urgent message; must be acknowledged.

1355

[Motor 5B] overload Non-urgent message; must be acknowledged.

1364

[Motor 6A] overload Non-urgent message; must be acknowledged.

1365

[Motor 6B] overload Non-urgent message; must be acknowledged.

8.4.8

Precommand

You can configure a corresponding precommand for each motor. This allows e.g. to

open a damper

or

valve prior to actual motor start as well as shut off the damper

delayed following motor switch-off.

Main menu > Commissioning > Extra configuration > Aggregates > Motor > Motor 1...6 >

Configuration

Operating line

Adjustable values / Comment

Precommand

---, N.Q1, N.Q2, ... (free outputs only)

The precommand switches on if switch-on takes place via start condition 1

or

2.

The motors can be started or stopped with the "Precommand" simultaneously

or

delayed. Set delayed switch-on/off via "Precommand runup time" and

"Precommand rundown time".

116 / 216

Siemens

Switching and monitoring device RMS705B

CE1P3124en

Building Technologies

Aggregates

01.04.2010