Direct programmer adjustment

Program set-points and segment times can be adjusted at the operating

page directly via the instrument front panel, without calling up the parame-

ter level. Direct access to parameter setting is enabled with control input

p-show

= „1" set at the function blocks of programmer APROG and

DPROG.

Menu item

Program

can be selected in the status line. After confirma-

tion, all segment parameters

Tp

and

Wp

pertaining to an effective recipe

Rec

can be displayed and adjusted in a scroll window (Fig. ). Return to

the normal operation is with

End

.

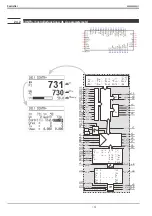

Scrolling is done over several data blocks (APROGD, DPROGD). „n" seg-

ment parameter (Wpn, Tn) indexing is with 3 digits. The segment parame-

ters are distributed to the concerned data blocks automatically from left to

right with ascending index (Fig. ).

If the last segment time Tn is adjusted to a valid value, the next parameter

Tn+1 is displayed automatically. =

--:--

etc.

Thus an actual program can also be reduced by setting Tn+1. =

--:--

in

the required position. The following segments are suppressed in the pro-

gram sequence.

However, the relevant segment parameters remain unchanged and are

made effective again by entry of a valid value at the relevant point.

Adjusting the programmer via the parameter level remains possible. In this

case, however, each data block APROGD or DPROGD must be selected

separately. In this case, however, parameters

W0

,

W100

and

Dp

pertaining to APROG are not effective.

Adjusting several recipes

In modes

run

,

stop

and

preset

, only the instanta-

neously effective recipe can be

processed as described. Further

recipes (

Rec

) can be changed

only with the programmer at

permanent reset. This is possi-

ble only with the reset input

connected. For this, e.g. the au-

tomatic/manual key can be used

(

f-key

r

reset

, see Fig.

).

Compatibility with earlier engineerings

Earlier engineerings are converted automatically with „operating version 3" ad-

justed. Adjustment of new parameters

W0

,

W100

and

Dp

is possible only

then. For using the adjustment via the scroll window, however, control input

p-show

must be connected previously.

Downward compatibility

As the additional functions in earlier KS 98 firmware versions are not known,

„Operating version 2" must be adjusted before transmission of the engineering.

KS 98 with new firmware version (from V2.1) cannot be processed with earlier

ET/KS 98 (

ß

V2.1)!

9499 040 50611

Programmer

151

APROG ( analog programmer ) / APROGD ( APROG data )

100: Programmgeber

Rec

=

1

Wp0

=

Wert

Tp1

=

Zeit

Wp1

=

Wert

Tp2

=

Zeit

Wp2

=

Wert

Tp3

=

Zeit

Wp3

=

Wert

Tp4

=

Zeit

.

.

.

Wpn

=

Wert

Tpn+1 =

--:--

Ende

Scrolling

Scrolling window

Automatic parameter distribution to data blocks

Fig.16: Perment reset

Summary of Contents for KS 98

Page 8: ...Description 9499 040 50611 Construction 8...

Page 10: ...Important technical data 9499 040 50611 Further external in and outputs 10...

Page 12: ...Versions 9499 040 50611 I O modules for units with modular option c basic card 12...

Page 14: ...Front view 9499 040 50611 14...

Page 16: ...Mounting 9499 040 50611 16...

Page 26: ...Maintenance 9499 040 50611 Further information 26...

Page 36: ...Scaling and calculating functions 9499 040 50611 LG10 10s logarithm 36...

Page 74: ...Signal converters 9499 040 50611 MEAN mean value formation 74...

Page 128: ...KS98 I O extensions with CANopen 9499 040 50611 RM_DMS strain gauge module 128...

Page 132: ...CSEND Send mod blockno s 21 23 25 27 No 57 132...

Page 140: ...Description of KS98 CAN bus extension 9499 040 50611 140...

Page 202: ...Controller 9499 040 50611 Process value calculation 202...