Setting

up Compax3

Positioning via digital I/Os

176

192-120101 N11 C3I11T11 November 2007

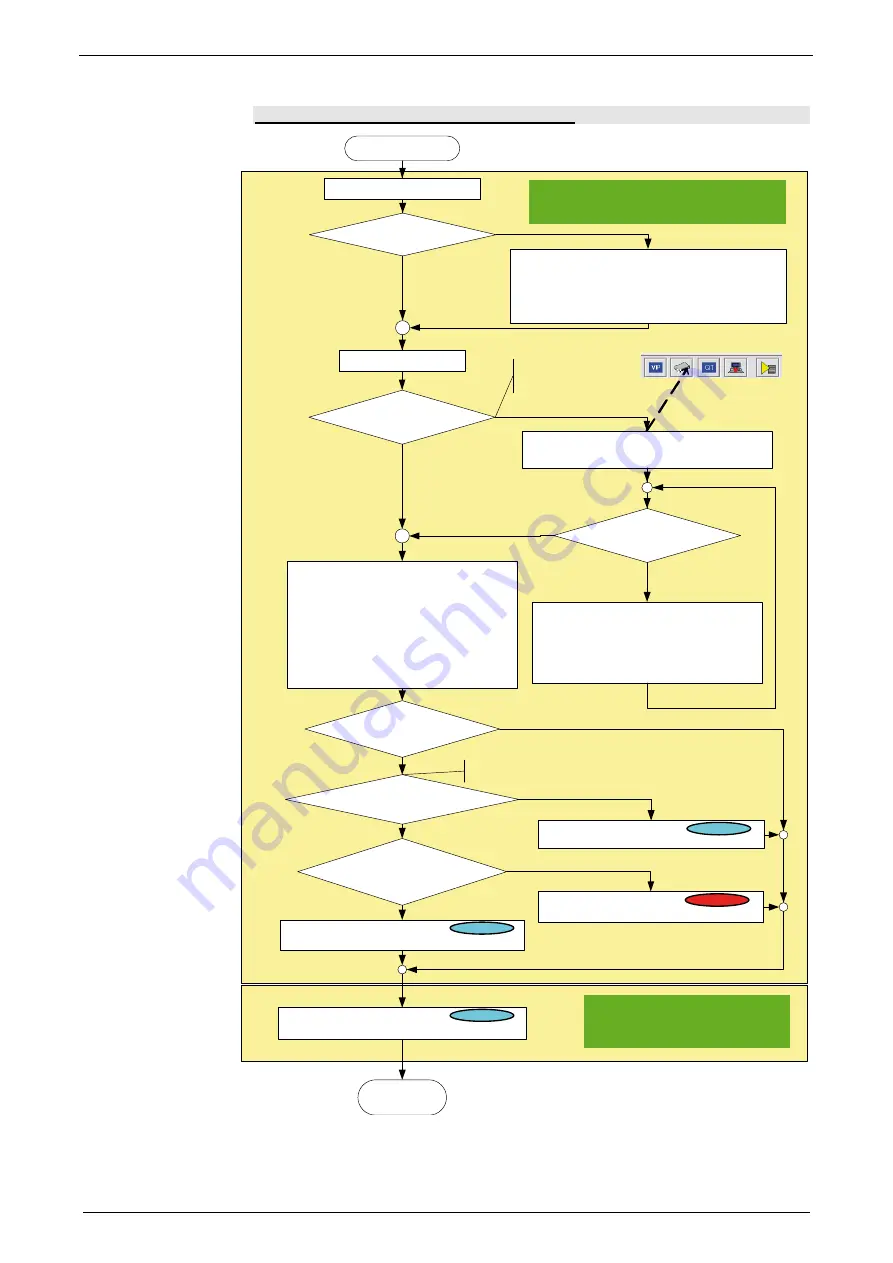

Main flow chart of the controller optimization

Is the controlled system oscillating ?

See chapter

“Controller optimization of toothed belt drive”

See chapter

“Controller optimization guiding behavior”

End

Start

Check consistency of the entire system :

•

Wiring

•

Acquisition of the feedback system

•

Configuration (motor type, mass inertia, path/

motor revolution)

•

...

no

Smooth, stable behavior?

Reduce stiffness (Obj. 2100.2) gradually by up to 80%.

Store into flash with Write Flash (WF)

yes

no

Optimization of the error and

setpoint behavior

Optimization of the

respon se behavior

See chapter

“Controller optimization direct drive”

yes

Is a LCB actuator used?

Energize

see chapter

“stability , attenuation”

Smooth, stable behavior

no

yes

yes

Optimizing the stiffness:

1. Standstill

•

Increase stiffness until drive hums, then reduce by

20%

2. Move slowly over the the positioning range

•

Increase stiffness until drive hums, then reduce by

10%

3. Move quickly (e.g. operating speed) over the

positioning range

•

Check behavior and reduce stiffness further if

necessary

Further optimization necessary?

See chapter “oscillating plants”

no

Is the controlled system a direct drive?

(Torque motor, linear motor, PowerRod)

yes

yes

no

no

See chapter

“Controller optimization standard”

Default:

1. Switch on advanced mode

2. Set

bandwidth of current control to30%

3. Set

stiffness to 70%

4. Set

control signal filter to3000µs

(only if no gear is present)

5. Activate VP and switch to standard

Standard

Standard

Advanced

Configuration of the application

Flash is a failure-save emory

Standard