6

-14

Using Highslip braking

When the system is operating, the Inverter is delivering an amount of electrical energy to the motor, this

energy is transformed into mechanical and thermal energy.

As a generator, the motor efficiency is still high. Most of the energy returns to the Inverter as current flow.

This regenerated current is stored in the DC bus capacitors, increasing the DC bus voltage. If the regenerated

energy is bigger than the Inverter losses (10% or less) the DC bus will increase to a level where the braking

resistor starts working. If no braking resistor is installed the DC voltage will increase up to a level where the

Inverter operation will be stopped and an overvoltage (OV) is shown.

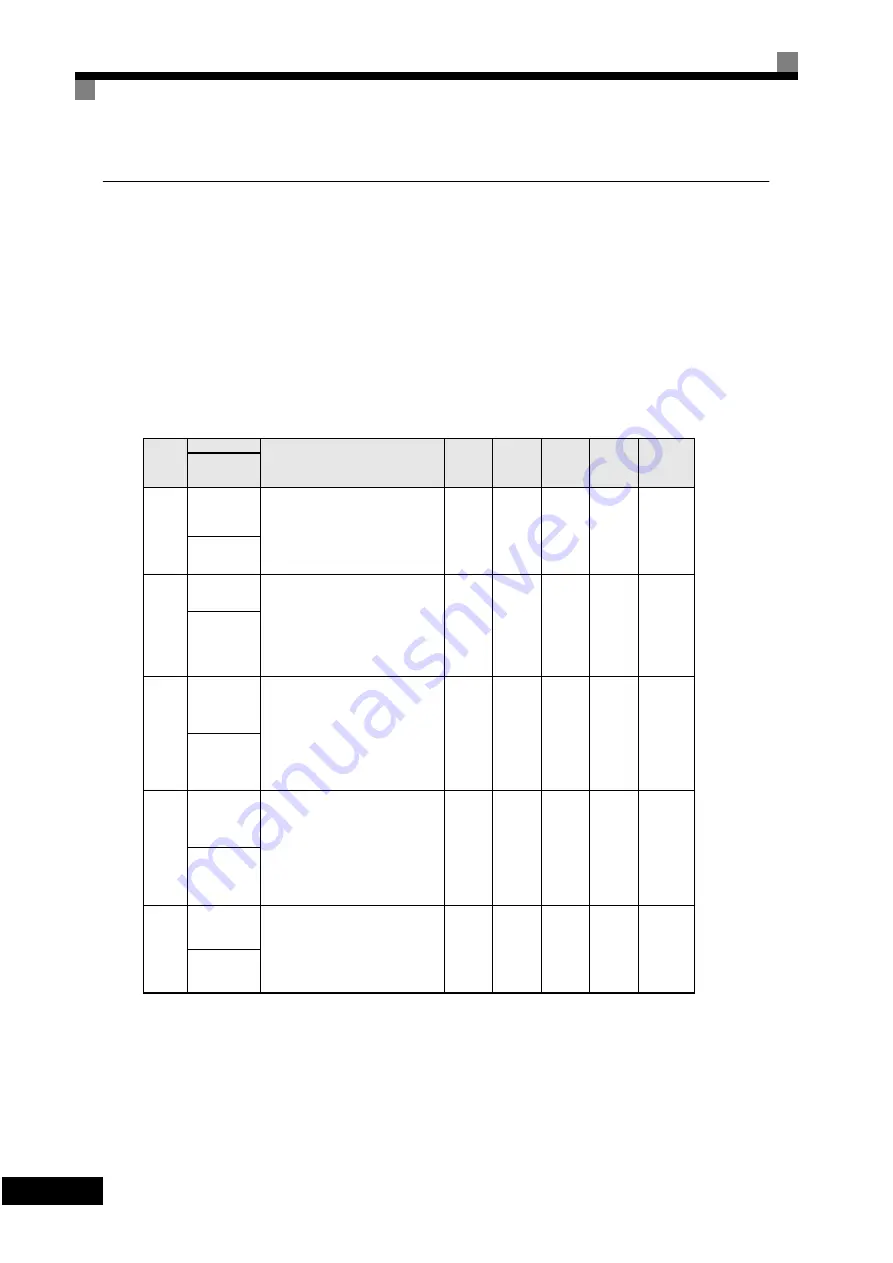

Related parameters

Param-

eter-

Number

Name

Description

Setting

Range

Factory

Setting

Change

during

Opera-

tion

Access

Level

RS-422A/

485

Register

LCD

Display

n3-01

High-slip brak-

ing decelera-

tion frequency

width

Sets the frequency width for

deceleration during high-slip

braking in percent, taking the

Maximum Frequency (E1-04) as

100%.

1 to 20

5%

No

A

588H

HSB Decel

Width

n3-02

High-slip brak-

ing current

limit

Sets the current limit for decelera-

tion during high-slip braking in

percent, taking the motor rated

current as 100%. The resulting

limit must be 150% of the Inverter

rated current or less.

100 to

200

150%

No

A

589H

HSB Current

Ref

n3-03

High-slip brak-

ing stop dwell

time

Sets the dwell time for the output

frequency for FMIN (1.5 Hz) dur-

ing V/f control.

Effective only during deceleration

for high-slip braking.

0.0 to

10.0

1.0 s

No

A

58AH

HSB Dwel-

Tim@Stp

n3-04

High-slip brak-

ing OL time

Set the OL time when the output

frequency does not change for

some reason during deceleration

for high-slip braking.

30 to

1200

40 s

No

A

58BH

HSB Ol Time

H1-01

-

H1-05

Terminal sel

S3-S7

Multifunction Digital Inputs

0 to 77

No

A

400H

to

404H

Terminal sel

S3-S7