7 - 12

LLE11ARDA001A/E

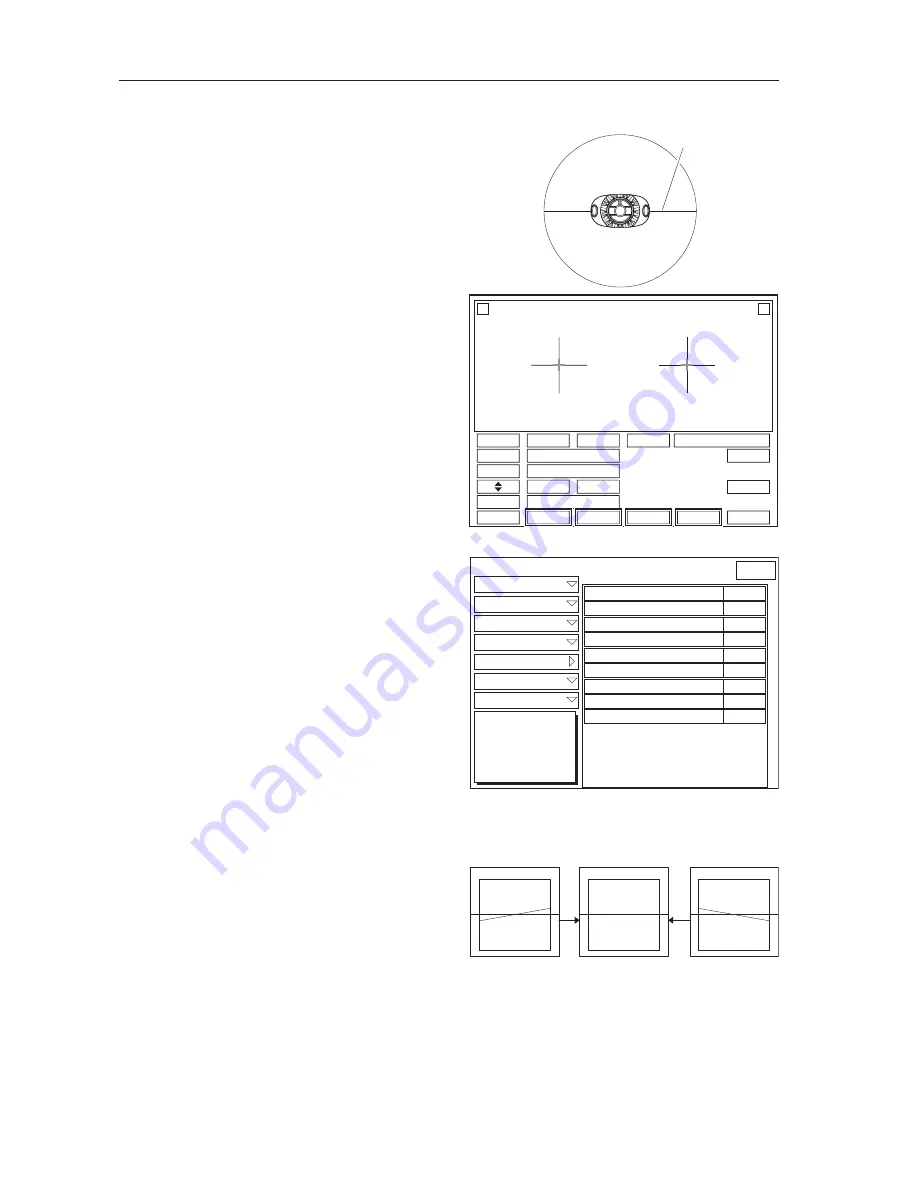

7.7 AXIS Adjustment

1. Draw a horizontal line in the middle of the

lens.

2. Block the lens cup to the lens to align it to the

horizontal line.

3. Read the stored lens data of square 45.

(See 7.2.4.)

4. Select the processing settings as below on the

layout screen.

1) Frame type

a. In bevel processing: Metal

b. In flat processing: Nylor

2) Processing mode: Auto

3) Polishing: NONE

4) S.F.B.: NONE

5. After the processing, measure the axis of the

lens with a graph paper and verify that it is

within the specified value

±

0.7 degree.

6. Adjust it by following the procedures below

when it is out of the specification.

1) Establish the Parameter Setting mode.

(See 7.1.2.)

2) Press Adjustment.

3) Press AXIS Adjustment.

4) Adjust the parameter settings below.

* Use the lens suitable for each parameter in

the adjustment.

a. CR39/Hi Index, Bevel

b. CR39/Hi Index, Flat

c. Polyca/Acrylic/Trivex, Bevel

d. Polyca/Acrylic/Trivex, Flat

e. Glass, Bevel

f. Glass, Flat

* Enter the plus value when the horizontal line

slants to the right viewing from the front of

the lens.

* Change the parameter settings in

±

0.1

increments.

* The parameter adjustment of the Glass, Bevel

and Glass, Flat are only for the wheel type of

PLB-G.

* The lens, which have been ground once, can be ground again to check by decreasing the size

in 3. However, finally verify that the axis angle does not displace when the size is 0.00.

* Use the lens cup for a half-eye lens not a pliable cup for the NIDEK cup specification.

*QTK\QPVCNNKPG

%4

5K\G

㪧㪛

㪝㪧㪛

&KURNC[

4+)*6

.'(6

/GVCN

#WVQ

2QNKUJ

'ZVGTP

010'

#EVKXG

㪤㪜㪥㪬

4

.

ь

Ǿ

ь

Ǿ

(2&%748'#0).'

%QXGT

4QWIJ5K\G

(KPKUJ5K\G

2QNKUJ5K\G

2QNKUJ&KHH

#:+5

5CHGV[$GXGN

)TQQXG&TKNN

Adjustment

%4*K+PFGZ$GXGN

%4*K+PFGZ(NCV

%4*K+PFGZ)TQQXG

2QN[EC#ET[NKE6TKXGZ$GXGN

2QN[EC#ET[NKE6TKXGZ(NCV

2QN[EC#ET[NKE6TKXGZ)TQQXG

)NCUU$GXGN

)NCUU(NCV

2QNKUJ

%4*K+PFGZ$GXGN

%4*K+PFGZ(NCV

%4*K+PFGZ)TQQXG

2QN[EC#ET[NKE6TKXGZ$GXGN

2QN[EC#ET[NKE6TKXGZ(NCV

2QN[EC#ET[NKE6TKXGZ)TQQXG

)NCUU$GXGN

)NCUU(NCV

2QNKUJ

BACK

Summary of Contents for ME-1000

Page 8: ...1 2 LLE11ARDA001A E...

Page 12: ...3 2 LLE11ARDA001A E...

Page 120: ...7 34 LLE11ARDA001A E...

Page 121: ...8 1 LLE11ARDA001A E 8 SUPPLEMENT 8 1 Wiring Diagram...

Page 122: ...8 2 LLE11ARDA001A E 8 2 Connector Cable...

Page 123: ...8 3 LLE11ARDA001A E...

Page 125: ...8 5 LLE11ARDA001A E 8 4 Labels Top view Processing chamber...

Page 126: ...8 6 LLE11ARDA001A E Rear view or...