ENGINE MAIN PARTS - INSPECTION AND CORRECTION

2 - 23

2. Flywheel, Timing Gear, Camshaft

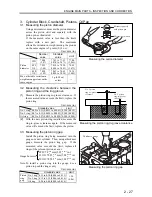

2.1 Measuring the flywheel flatness

Place the flywheel on a surface plate. Run a dial

gauge over the frictional surface of the flywheel

to measure the flatness.

If the measured value exceeds the limit, grind the

frictional surface.

Unit: mm (in.)

Standard

value

Limit

Flywheel flatness

0.150 (0.0059)

or less

0.50 (0.0197)

2.2 Replacing the ring gear

Check the ring gear for fractured or excessively

worn gear teeth. If faulty, replace in the

following manner.

(1)

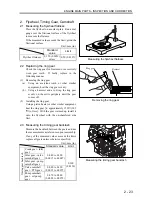

Removing the ring gear

(a) Using an acetylene torch or other similar

equipment, heat the ring gear evenly.

(b) Using a hammer and a rod, tap the ring gear

evenly on the entire periphery until the gear

comes off.

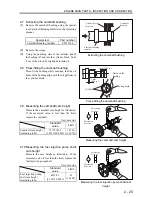

(2)

Installing the ring gear

Using a piston heater or other similar equipment,

heat the ring gear [to approximately 150

℃

(302

°

F

) or less]. With the gear warmed up, install it

onto the flywheel with the un-chamfered side

first.

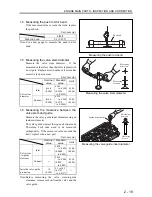

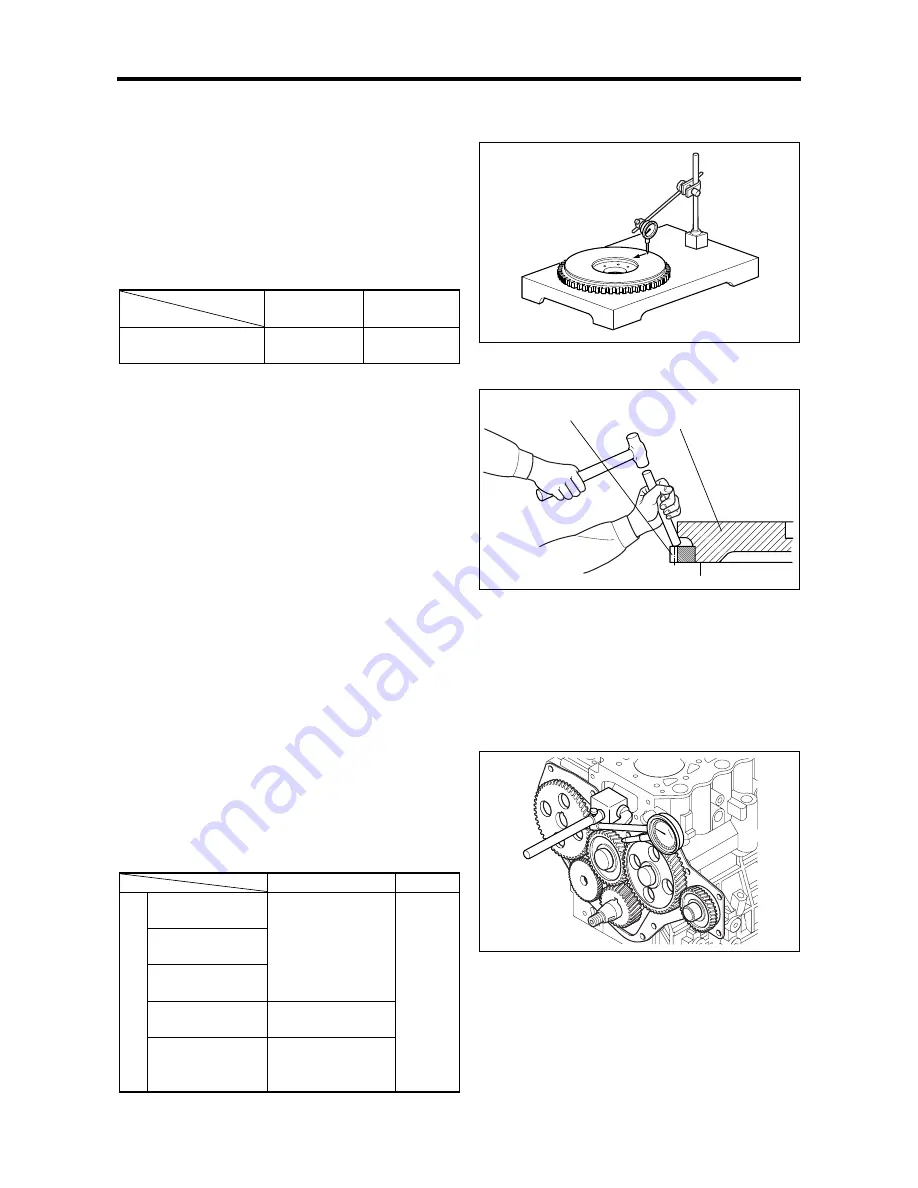

2.3 Measuring the timing gear backlash

Measure the backlash between the gears and use

the measurements as references upon reassembly.

If any of the measured values exceeds the limit,

replace all gears unless otherwise specified.

Unit: mm (in.)

Standard

value

Limit

Crank gear - idler

gear

Idler gear - valve

camshaft gear

Idler gear - pump

camshaft gear

0.040 to 0.120

(0.0015 to 0.0047)

Valve camshaft

gear - PTO gear

0.080 to 0.190

(0.0032 to 0.0075)

T

iming gear backlash Pump camshaft

gear - oil pump

gear

0.070 to 0.200

(0.0028 to 0.0079)

0.300

(0.0120)

Measuring the flywheel flatness

Removing the ring gear

Measuring the timing gear backlash

Flywheel

Ring gear

Summary of Contents for diesel engines

Page 5: ......

Page 33: ...SERVICE STANDARDS 1 20 ...

Page 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Page 37: ...TOOLS LIST 1 24 ...

Page 41: ...OVERHAUL TIMING 1 28 ...

Page 46: ......

Page 47: ......

Page 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Page 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Page 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Page 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Page 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Page 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Page 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Page 150: ......

Page 151: ......

Page 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Page 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Page 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Page 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Page 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Page 207: ...MISCELLANEOUS 9 4 ...