ENGINE MAIN PARTS - INSPECTION AND CORRECTION

2 - 21

(4)

If the measured valve head sinkage exceeds the

limit, correct the valve seat or replace the

cylinder head assembly.

Unit: mm (in.)

Standard

value

Limit

Valve head sinkage

0.25 to 0.75

(0.0098

±

0.0295)

1.5

(0.0600)

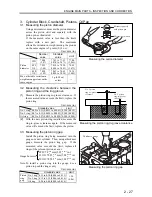

1.9 Correcting the valve face

If the valve face is excessively worn, correct with

a valve refacer.

Note: (a) When grinding, set the refacer at 45º relative

to the valve face.

(b) The valve head margin should be maintained

above the limit. If it appears that the

minimum margin cannot be maintained after

refacing, replace the valve.

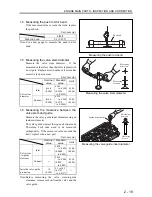

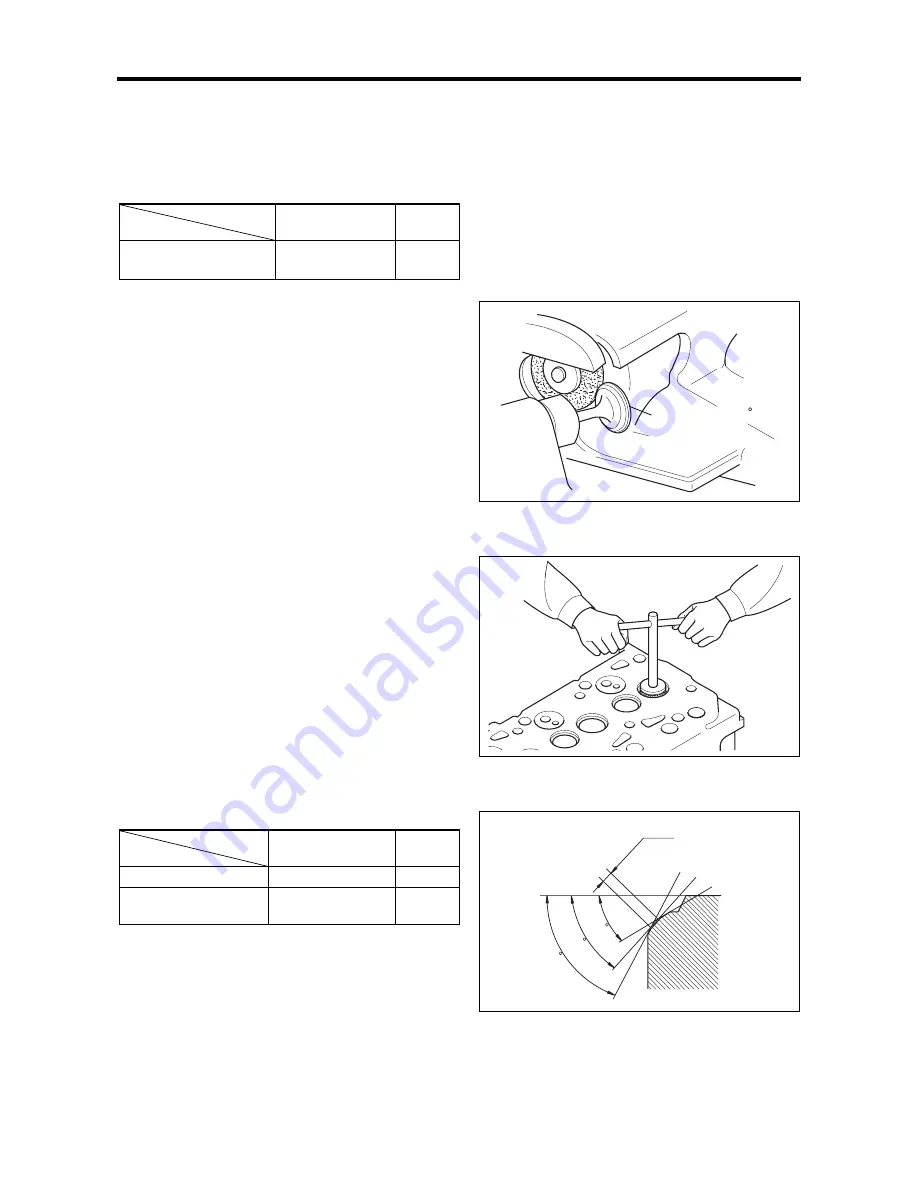

1.10 Correcting the valve seat

(1)

Before correcting the valve seat, check the valve

stem-to-guide clearance and, if necessary,

replace the valve guide.

(2)

Grind with a valve seat cutter (available on the

market) or a valve seat grinder until the valve seat

width and angle meet specification.

Note:

Valve seat correction should be limited as

minimum as possible.

Unit: mm (in.)

Standard

value

Limit

Valve seat angle

45°

―

Valve seat width

1.30 to 1.80

(0.0512 to 0.0709)

2.5

(0.0985)

(3) After correction, lap the valve face against the

valve seat using lapping compound.

Correcting the valve face

Correcting the valve seat

Valve seat angle and width

Refacer set at 45

relative to the

valve face

Valve contact width

1.3 to 1.8 mm

(0.05 to 0.07 in.)

60

45

30

Summary of Contents for diesel engines

Page 5: ......

Page 33: ...SERVICE STANDARDS 1 20 ...

Page 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Page 37: ...TOOLS LIST 1 24 ...

Page 41: ...OVERHAUL TIMING 1 28 ...

Page 46: ......

Page 47: ......

Page 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Page 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Page 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Page 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Page 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Page 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Page 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Page 150: ......

Page 151: ......

Page 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Page 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Page 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Page 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Page 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Page 207: ...MISCELLANEOUS 9 4 ...