FUEL SYSTEM - DISASSEMBLY, INSPECTION AND REASSEMBLY

3 - 17

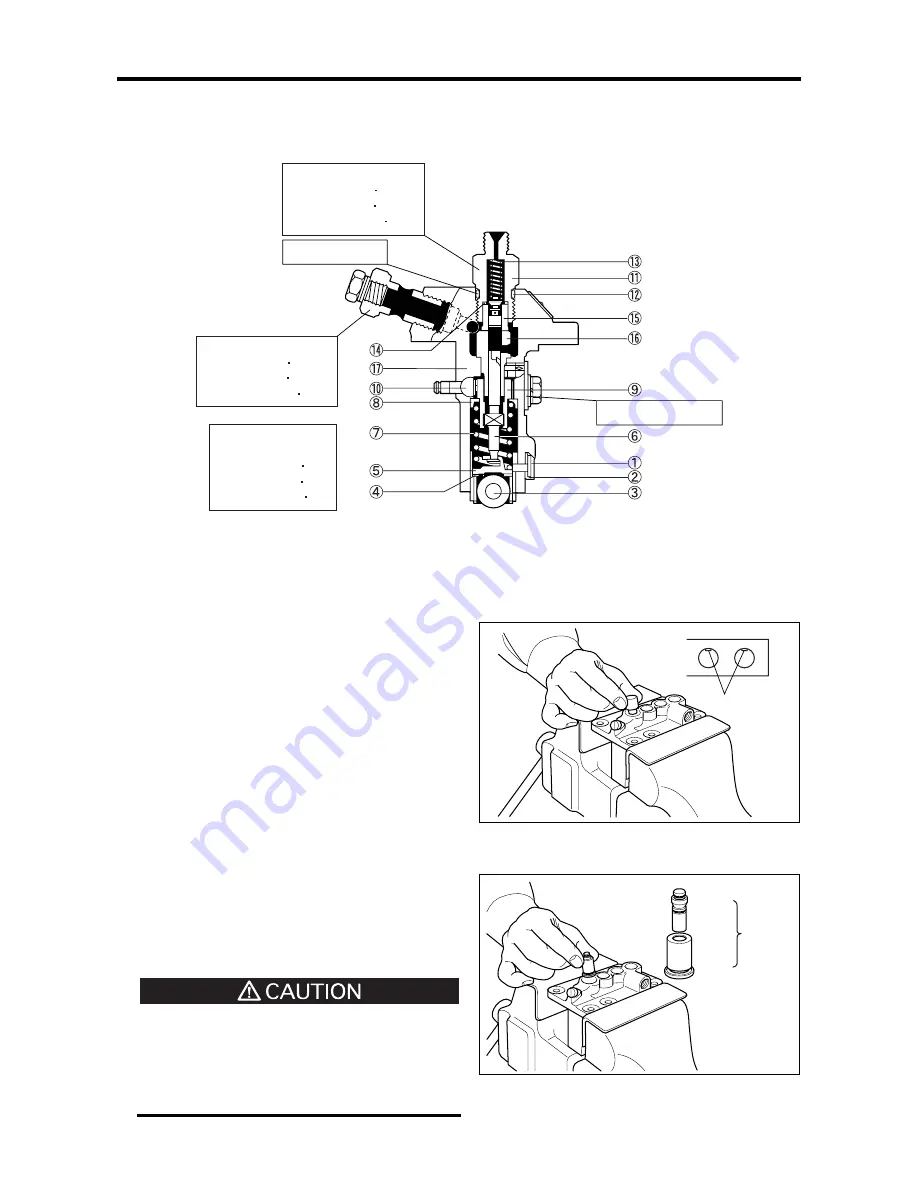

2.4 Reassembling the fuel injection pumps

Air bleed plug

Tightening torque:

9.81 to 13.7 N m

(1.0 to 1.4 kgf m)

[7.2 to 10.1 lbf ft]

Replace: O-ring

Replace: Lock plate

Tightening torque:

39.2 to 49.0 N m

(4.0 to 5.0 kgf m)

[28.9 to 36.2 lbf ft]

Tightening torque:

19.6 to 24.5 N m

(2.0 to 2.5 kgf m)

[14.5 to 18.1 lbf ft]

Reassembly of the fuel injection pumps

To reassembly, follows the disassembly sequence in reverse and do the following steps.

(1)

Inserting the plunger barrels

Ensure that the plunger barrel groove is aligned

with the knock pin of the pump housing.

Note: If the plunger barrel groove is not aligned with

the knock pin, the O-ring will not seat properly in

the pump housing when the delivery valve holder

is being loosely tightened in the next operation.

(2)

Installing the delivery valves

Install the delivery valve, gasket, spring and

O-ring. Loosely tighten the delivery valve

holder.

(a) Discard the old O-ring. Replace with a new

part.

(b) While reassembling, take care not to cut the

O-ring with the threaded portion of the valve

holder.

Inserting the plunger barrel

Installing the delivery valve

Knock pin

Valve

Valve

seat

Delivery

valve

Summary of Contents for diesel engines

Page 5: ......

Page 33: ...SERVICE STANDARDS 1 20 ...

Page 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Page 37: ...TOOLS LIST 1 24 ...

Page 41: ...OVERHAUL TIMING 1 28 ...

Page 46: ......

Page 47: ......

Page 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Page 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Page 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Page 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Page 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Page 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Page 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Page 150: ......

Page 151: ......

Page 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Page 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Page 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Page 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Page 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Page 207: ...MISCELLANEOUS 9 4 ...