OVERHAUL TIMING

1 - 27

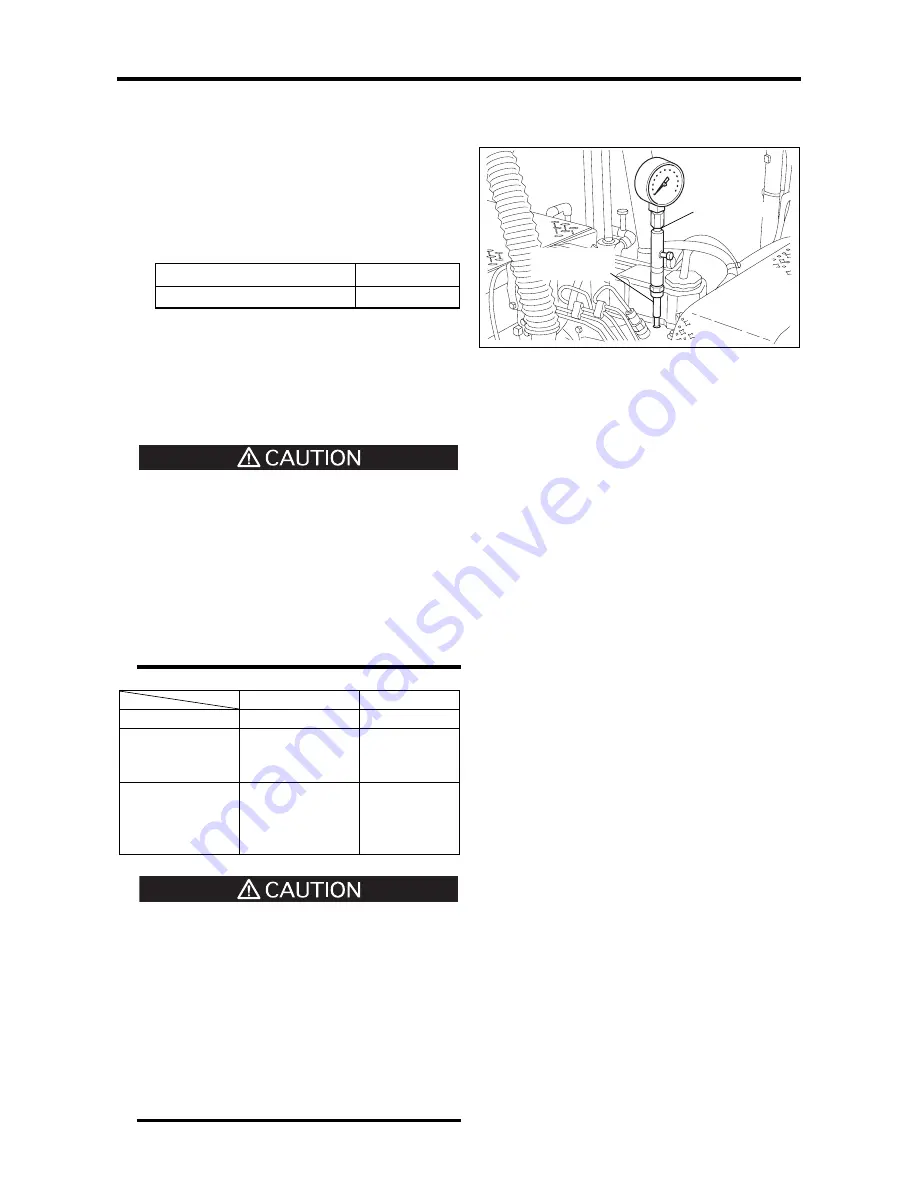

2. Measuring the Compression Pressure

(1)

Move the control lever to STOP position.

(2)

Remove the glow plugs from all cylinders.

Install the special tool Compression Gauge

Adapter and a compression gauge onto the

cylinder being measured.

Special tool

Part number

Compression Gauge Adapter

ST332270

(3)

While cranking the engine with the starter, read

the compression gauge. Note the reading at

which the gauge needle stabilizes.

(4)

If the measured value is at or below the limit,

overhaul the engine.

(a)

Measure all cylinders for compression

pressure. Do not measure only one

cylinder and make assumption about the

other cylinders as this will lead to a wrong

conclusion.

(b)

Compression pressure varies depending

on the engine speed. Keep the specified

engine speed when measuring the

compression pressure.

Standard

value

Limit

Engine speed

290 min

-1

Compression

pressure

2.9 MPa

(30 kgf/cm

2

)

[421 psi]

2.6 MPa

(27 kgf/cm

2

)

[377 psi]

Tolerable

difference

between

cylinders

0.29 MPa

(3.0 kgf/cm

2

)

[42 psi]

or less

It is important to regularly check the

compression pressure so that you can tell the

difference.

・

New or overhauled engines have slightly

higher compression pressure.

・

The compression pressure settles to the

standard value as the piston rings and

valve seats fit in.

・

As wear progresses further, the

compression pressure drops.

Compression

gauge adapter

Compression

gauge

Measuring the compression pressure

Summary of Contents for diesel engines

Page 5: ......

Page 33: ...SERVICE STANDARDS 1 20 ...

Page 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Page 37: ...TOOLS LIST 1 24 ...

Page 41: ...OVERHAUL TIMING 1 28 ...

Page 46: ......

Page 47: ......

Page 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Page 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Page 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Page 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Page 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Page 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Page 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Page 150: ......

Page 151: ......

Page 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Page 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Page 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Page 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Page 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Page 207: ...MISCELLANEOUS 9 4 ...