ELECTRICAL SYSTEM - DISASSEMBLY, INSPECTION AND REASSEMBLY

7 - 17

(3)

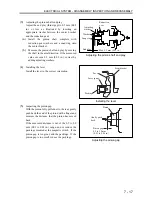

Adjusting the pinion shaft end play

Adjust the end play (thrust gap) to 0.5 mm (0.02

in.) or less as illustrated by inserting an

appropriate washer between the center bracket

and the reduction gear.

(a)

Install the pinion shaft complete with

reduction gear washers and a snap ring onto

the center bracket.

(b)

Measure the pinion shaft end play by moving

the shaft in the axial direction. If the measured

value exceeds 0.5 mm (0.02 in.), correct by

adding adjusting washers.

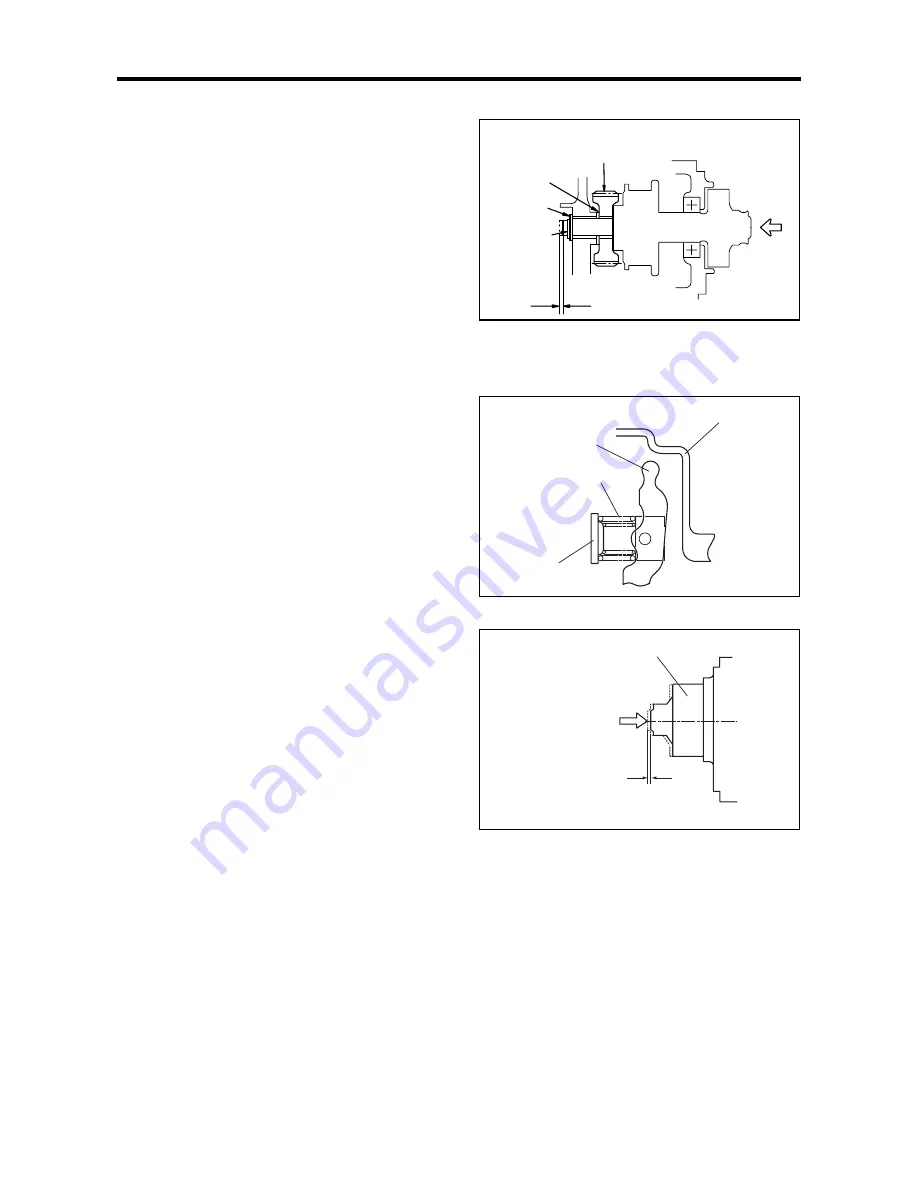

(4)

Installing

the

lever

Install the lever in the correct orientation.

(5)

Inspecting the pinion gap

With the pinion fully pulled out to the rear, gently

push back the end of the pinion with a finger and

measure the distance that the pinion has moved

back.

If the measured distance is out of the 0.5 to 2.0

mm (0.02 to 0.08 in.) range, add or reduce the

packings mounted at the magnetic switch. If the

pinion gap is too great, add the packings. If the

pinion gap is too small, reduce the packings.

Adjusting the pinion shaft end play

Installing the lever

Adjusting the pinion gap

Max. 0.5 mm (0.02 in.)

End play

Snap ring

Washer

Adjusting

washer

Reduction

gear

Front bracket

Lever

Lever spring

Packing

Gently push

back.

Pinion gap

0.5 to 2.0 mm

(0.02 to 0.08 in.)

Pinion

Summary of Contents for diesel engines

Page 5: ......

Page 33: ...SERVICE STANDARDS 1 20 ...

Page 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Page 37: ...TOOLS LIST 1 24 ...

Page 41: ...OVERHAUL TIMING 1 28 ...

Page 46: ......

Page 47: ......

Page 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Page 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Page 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Page 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Page 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Page 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Page 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Page 150: ......

Page 151: ......

Page 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Page 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Page 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Page 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Page 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Page 207: ...MISCELLANEOUS 9 4 ...