ENGINE MAIN PARTS - INSPECTION AND CORRECTION

2 - 19

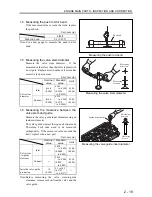

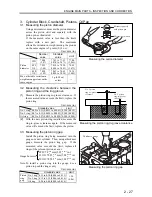

1.4 Measuring the push rod for bend

If the measured value exceeds the limit, replace

the push rod.

Unit: mm (in.)

Limit

Push rod bend

0.3 (0.012)

Note: Use a dial gauge to measure the push rod for

bend.

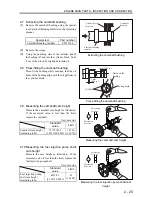

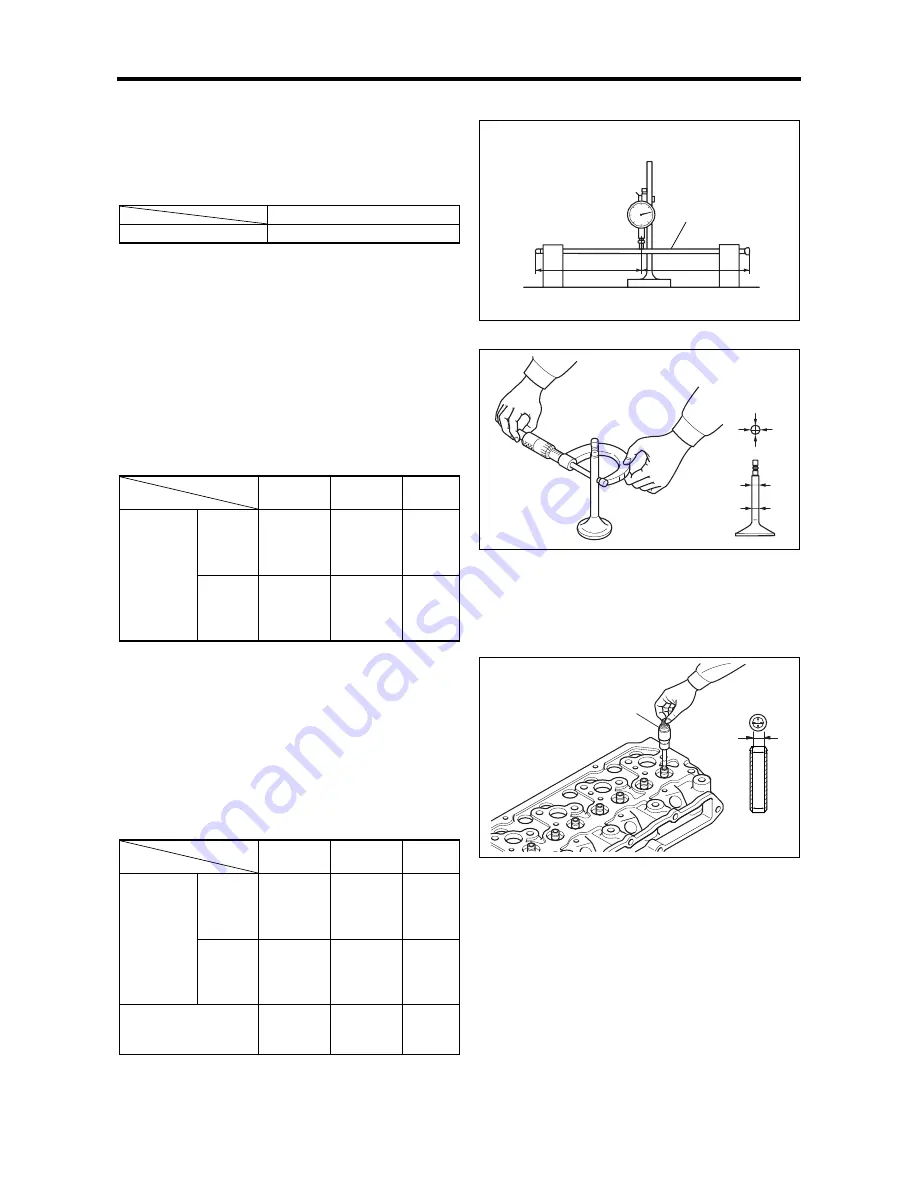

1.5 Measuring the valve stem diameter

Measure the valve stem diameter. If the

measured value is less than the limit, replace with

a new part. Replace also when the valve stem has

excessively uneven wear.

Unit: mm (in.)

Nominal

value

Standard

value

Limit

Inlet

φ

6.6

(0.260)

6.565

to 6.580

(0.2586

to 0.2592)

6.500

(0.256)

Valve stem

diameter

Exhaust

φ

6.6

(0.260)

6.530

to 6.550

(0.2572

to 0.2580)

6.500

(0.256)

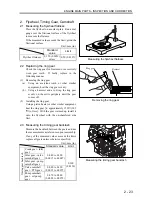

1.6 Measuring the clearance between the

valve stem and guide

Measure the valve guide inner diameter using an

inside micrometer.

The valve guide wears at the top and bottom ends.

Therefore, both ends need to be measured

orthogonally. If the measured value exceeds the

limit, replace with a new part.

Unit: mm (in.)

Nominal

value

Standard

value

Limit

Inlet

―

0.020

to 0.050

(0.0008

to 0.002)

0.100

(0.004)

Valve stem

-to-guide

clearance

Exhaust

―

0.050

to 0.085

(0.002

to 0.003)

0.150

(0.006)

Installed valve guide

protrusion

10

(0.394)

9.5 to 10.5

(0.3743

to 0.4137)

―

Note:

Before measuring the valve stem-to-guide

clearance, remove carbon from the valve and the

valve guide.

Measuring the valve stem diameter

Measuring the push rod bend

1/2

1/2

Push rod

Measuring the valve guide inner diameter

Measuring

direction

Measuring

location

Inside micrometer

Measuring

direction

Measuring

location

Summary of Contents for diesel engines

Page 5: ......

Page 33: ...SERVICE STANDARDS 1 20 ...

Page 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Page 37: ...TOOLS LIST 1 24 ...

Page 41: ...OVERHAUL TIMING 1 28 ...

Page 46: ......

Page 47: ......

Page 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Page 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Page 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Page 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Page 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Page 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Page 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Page 150: ......

Page 151: ......

Page 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Page 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Page 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Page 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Page 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Page 207: ...MISCELLANEOUS 9 4 ...