SERVICE STANDARDS

1 - 13

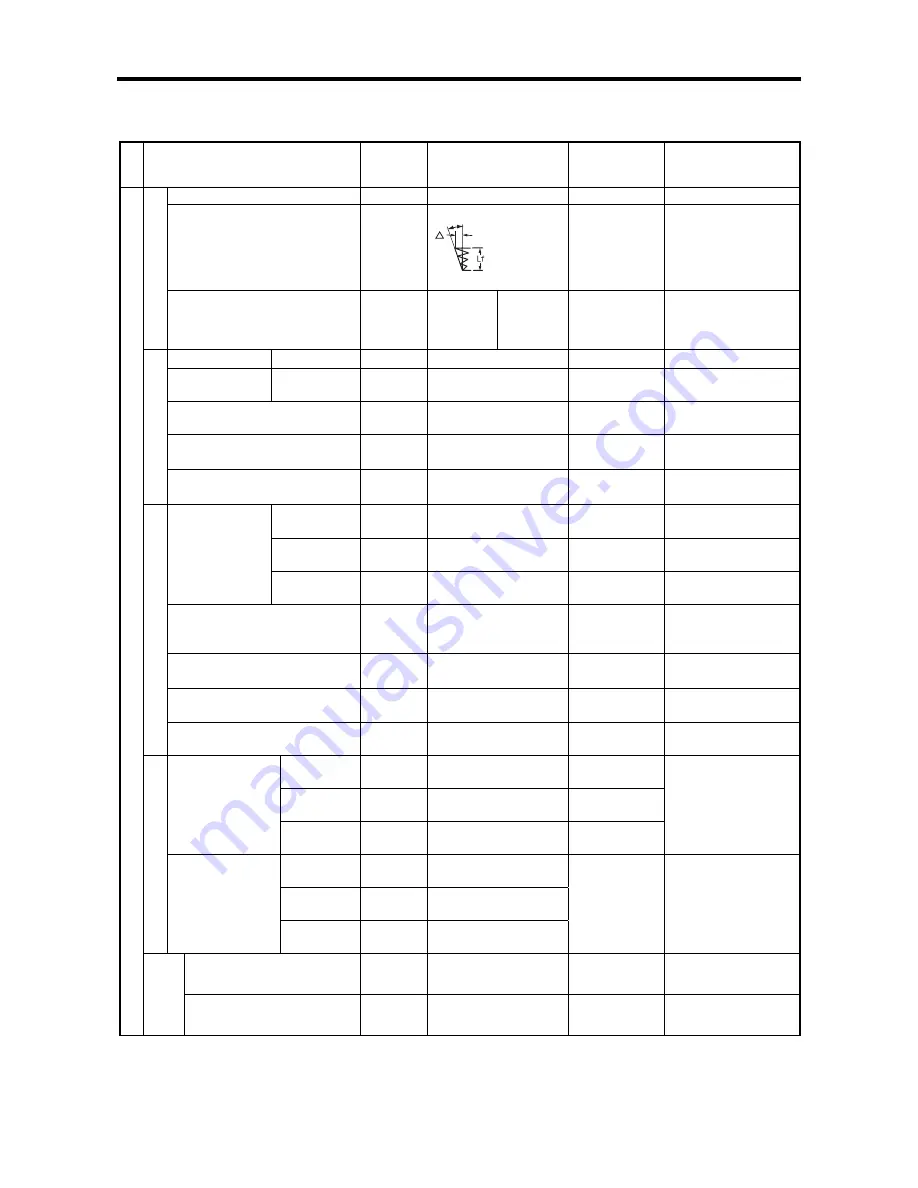

Unit: mm (in.)

Gro

up

Item

Nominal

value

Standard value

Limit

Remarks

Free length

47 (1.85)

46 (1.81)

Squareness

θ

=2.0°

Δ

=0.2

(0.0079)

Lf=47

(1.8518)

△

= 0.5

(0.0197)

across the

entire length

V

al

ve s

pri

ng

Installed length

/

load

mm (in.)/N (kgf) [lbf]

39.0 (1.536)/

131 to 145

(13.3 to 14.7)

[29 to 33]

30.1 (1.185)/

279 to 309

(28.5 to 31.5)

[63 to 69]

-15 %

Push rod

Bend

―

0.3 (0.011)

Replace

Cylinder head

Bottom face

distortion

0.05 (0.002)

or less

0.10 (0.004)

Correct

Cylinder block top face

distortion

0.05 (0.002)

or less

0.10 (0.004)

Correct

Bore

φ

78

(3.07)

78.0

+0.03

0

(3.07

+0.0012

0

)

78.2 (3.08)

Bore or replace

C

yl

inde

r

Out of roundness

±

0.01 (0.0004)

or less

―

STD

78.00

(3.07)

77.93 to 77.95

(3.070 to 3.071)

77.80

(3.065)

0.25 OS

78.25

(3.08)

78.18 to 78.20

(3.080 to 3.081)

78.05

(3.075)

Diameter

0.50 OS

78.50

(3.09)

78.43 to 78.45

(3.090 to 3.090)

78.30

(3.085)

Max. allowable variation in

weight among pistons on the

same engine

±

5 g (0.177 oz)

or less

―

Piston pin diameter

φ

23

(0.9062)

22.944 to 23.000

(0.9039 to 0.9062)

―

Piston pin-to-boss clearance

0.006 to 0.018

(0.0002 to 0.0007)

0.050

(0.002)

Pi

st

on

Piston-to-cylinder clearance

0.035 to 0.086

(0.0014 to 0.0034)

0.300

(0.012)

Bore or replace

No. 1 ring

0.09 to 0.11

(0.0035 to 0.0043)

0.300

(0.012)

No. 2 ring

0.07 to 0.11

(0.0028 to 0.0043)

0.200

(0.008)

Piston

ring-to-groove

clearance

Oil ring

0.03 to 0.07

(0.0012 to 0.0028)

0.200

(0.008)

Replace piston ring

No. 1 ring

0.15 to 0.30

(0.006 to 0.012)

No. 2 ring

0.15 to 0.35

(0.006 to 0.014)

Piston ring

Piston ring gap

Oil ring

0.20 to 0.40

(0.008 to 0.016)

1.50

(0.06)

Replace

Bend and twist

0.05/100

(0.002/3.940)

0.15/100

(0.006/3.940)

Engine mai

n

p

a

rt

s

Co

nn

ecting

ro

d

End play

0.10 to 0.35

(0.004 to 0.014)

0.50

(0.020)

Replace connecting

rod

θ

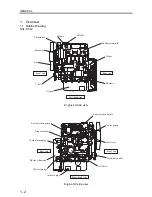

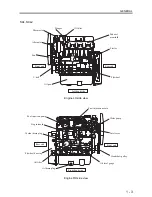

Summary of Contents for diesel engines

Page 5: ......

Page 33: ...SERVICE STANDARDS 1 20 ...

Page 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Page 37: ...TOOLS LIST 1 24 ...

Page 41: ...OVERHAUL TIMING 1 28 ...

Page 46: ......

Page 47: ......

Page 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

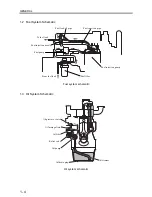

Page 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Page 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

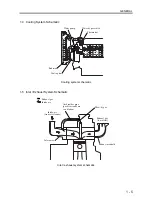

Page 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Page 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Page 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Page 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Page 150: ......

Page 151: ......

Page 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Page 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Page 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Page 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Page 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Page 207: ...MISCELLANEOUS 9 4 ...