ENGINE - INSPECTION

/

ADJUSTMENT, RUNNING-IN TRIAL AND PERFORMANCE TEST

8 - 6

1.5 Alternative adjustment method

Removing the delivery valve to check and adjust

the fuel injection timing is a sure way to observe

fuel coming out and stop. However, this also

runs the risk of allowing foreign matter to enter

into the system. The following alternative

method can be tried which allows you to check

the fuel injection timing without removing the

delivery valve.

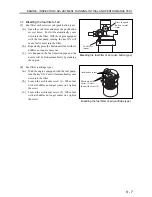

(1)

Disconnect the No. 1 fuel injection pipe at the

nozzle holder end.

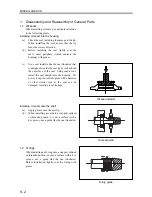

(2)

Slowly rotate the crankshaft clockwise while

observing the open end of the pipe. When fuel

starts to bulge out from the pipe end, check the

location of the IT mark on the crankshaft pulley.

In this case, allow for approx. 1º from the

specified fuel injection timing.

Note:

Bleed the system of air before rotating the

crankshaft.

1.6 Replacing the fuel filter

(1)

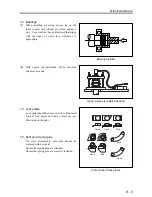

Fuel filter with selector cock

(a)

Close the cock lever. Loosen the ring nut, then

remove the filter element.

(b)

Install a new filter element.

(c)

Using a new O-ring, tighten the ring nut.

(d)

Open the cock lever. Bleed the filter of air.

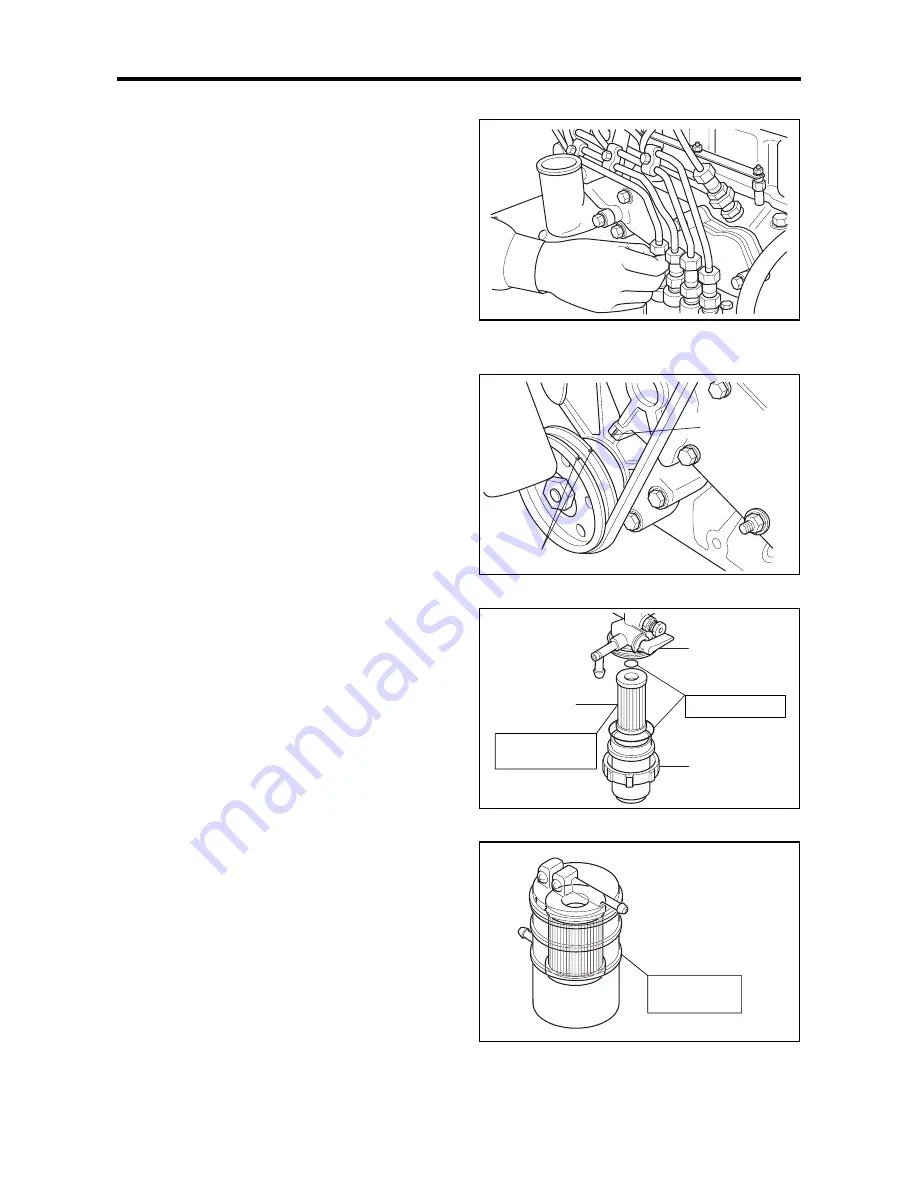

(2)

Fuel filter (cartridge type)

Replace the entire fuel filter assembly. After

replacement, bleed the filter of air.

Removing the No. 1 fuel injection pipe

Timing marks (2)

Counter mark on

gear case

IT mark

Replacing the fuel filter

Replace also when water or sediment has

accumulated inside.

Replace:

every 500 hours

Replace: O-ring

Cock lever

(closed)

Filter element

Ring nut

Replace:

every 500 hours

Replace also when water

or sediment has

accumulated inside.

Summary of Contents for diesel engines

Page 5: ......

Page 33: ...SERVICE STANDARDS 1 20 ...

Page 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Page 37: ...TOOLS LIST 1 24 ...

Page 41: ...OVERHAUL TIMING 1 28 ...

Page 46: ......

Page 47: ......

Page 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Page 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Page 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Page 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Page 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Page 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Page 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Page 150: ......

Page 151: ......

Page 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Page 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Page 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Page 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Page 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Page 207: ...MISCELLANEOUS 9 4 ...