OIL SYSTEM - DISASSEMBLY, INSPECTION AND REASSEMBLY

4 - 7

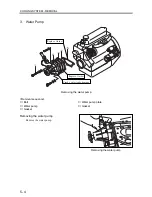

3. Oil Pressure Switch

Inspecting the oil pressure switch

(1)

Connect a tester (ohm meter) between the oil

pressure switch terminal and the switch body.

The tester should indicate continuity. If not,

replace the switch.

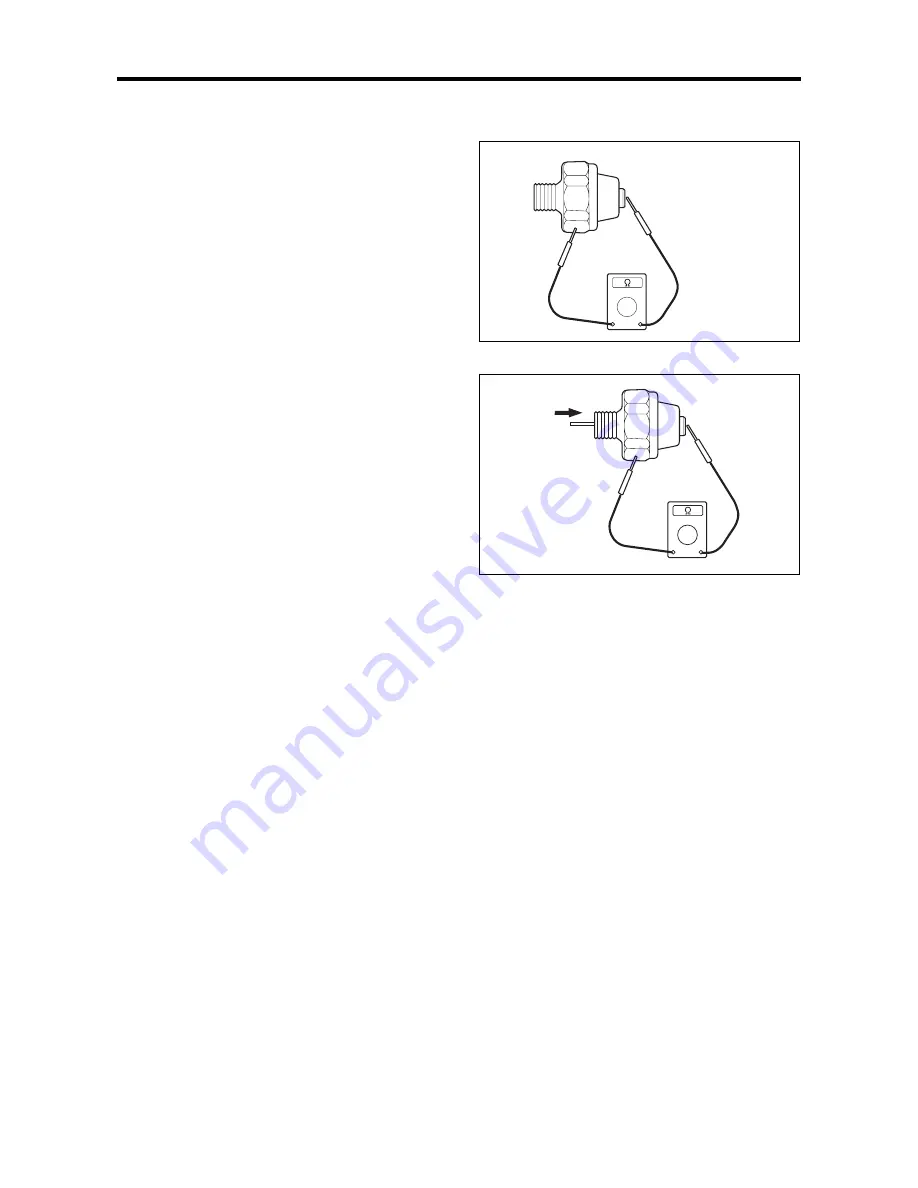

(2)

With the tester still installed, insert a thin rod into

the oil hole and gently press the rod. The tester

should indicate no continuity. If continuity is

indicated, replace the switch.

(3)

With the tester still installed, apply an air

pressure of 0.05 MPa (0.5 kgf/cm

2

) [7 psi] into

the oil hole. The tester should indicate no

continuity.

Check also for any air leakage. If air is leaking,

the diaphragm is broken. Replace the switch.

Inspecting the oil pressure switch (1)

Inspecting the oil pressure switch (2)

Check for continuity

Thin rod

Summary of Contents for diesel engines

Page 5: ......

Page 33: ...SERVICE STANDARDS 1 20 ...

Page 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Page 37: ...TOOLS LIST 1 24 ...

Page 41: ...OVERHAUL TIMING 1 28 ...

Page 46: ......

Page 47: ......

Page 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Page 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Page 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Page 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Page 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Page 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Page 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Page 150: ......

Page 151: ......

Page 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Page 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Page 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Page 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Page 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Page 207: ...MISCELLANEOUS 9 4 ...