ENGINE MAIN PARTS - REASSEMBLY

2 - 38

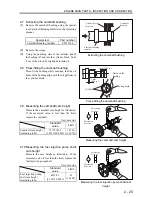

1.8 Installing the connecting rod caps

(1)

While pressing the top of piston down to keep

the connecting rod large end attached to the

crank pin, rotate the crankshaft 180°.

(2)

Install the connecting rod bearing (lower) onto

the connecting rod cap, ensuring that the lug

engages with the lug groove.

(3)

Install the bearing cap onto the connecting rod,

observing the mating marks made during

disassembly.

Note: If a new connecting rod without mating marks is

being installed, ensure that the lug grooves,

designed to prevent the bearings from turning,

are assembled on the same side.

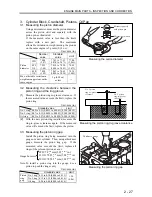

(4)

Tighten the connecting rod cap nuts alternately

in several steps, and finally to the specified

torque.

(5)

Check the connecting rod end play.

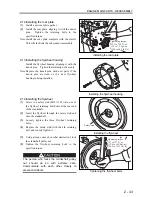

1.9 Installing the oil strainer

(1)

Position the cylinder block with the oil pan

mounting face up.

(2)

Install the oil strainer so that the tip of the

strainer will not contact the oil pan when

installed. Tighten the nut to the specified

torque.

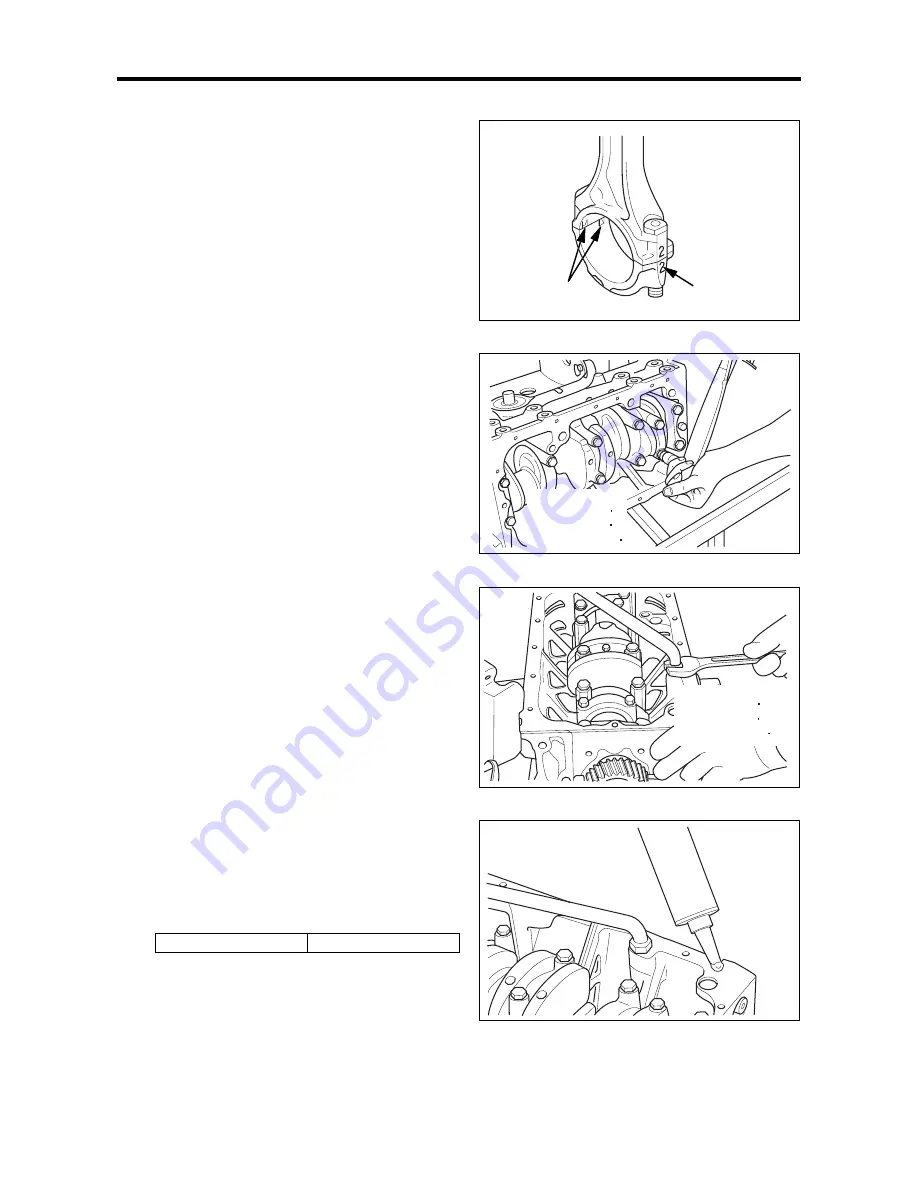

1.10 Installing the oil pan

(1) Clean the mating faces of the cylinder block and

the oil pan.

Apply sealant to the entire periphery of the oil

pan mounting face of the cylinder block.

Sealant ThreeBond

1207C

Installing the connecting rod cap

Tightening the connecting rod cap nuts

Installing the oil strainer

Applying sealant to the oil pan mounting face

of the cylinder block

Lug groove

Cylinder No.

Tightening torque:

32.4 to 37.3 N m

(3.3 to 3.8 kgf m)

[23.9 to 27.5 lbf ft]

Tightening torque:

24.5 to 29.4 N m

(2.5 to 3.0 kgf m)

[18.1 to 21.7 lbf ft]

Summary of Contents for diesel engines

Page 5: ......

Page 33: ...SERVICE STANDARDS 1 20 ...

Page 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Page 37: ...TOOLS LIST 1 24 ...

Page 41: ...OVERHAUL TIMING 1 28 ...

Page 46: ......

Page 47: ......

Page 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Page 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Page 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Page 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Page 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Page 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Page 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Page 150: ......

Page 151: ......

Page 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Page 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Page 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Page 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Page 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Page 207: ...MISCELLANEOUS 9 4 ...