SERVICE STANDARDS

1 - 16

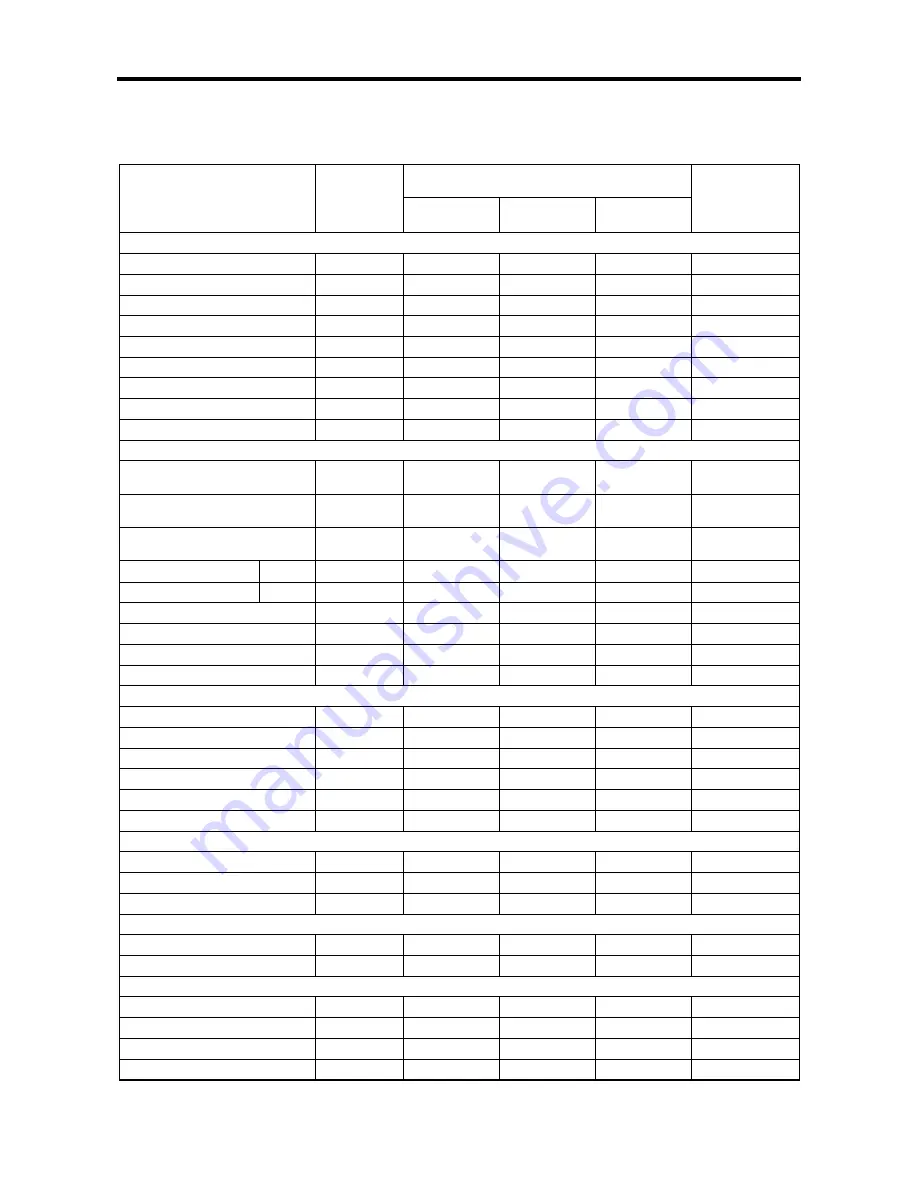

2. Tightening Torques Table

2.1 Major Bolts and Nuts

Tightening torque

Fittings

Thread

diameter

×

pitch

(mm)

N

・

m kgf

・

m lbf

・

ft

Remarks

Engine proper

Cylinder head bolt

M10

×

1.75

83.4 to 93.2

8.5 to 9.5

61.5 to 68.7

Rocker cover bolt

M8

×

1.25

9.81 to 12.7

1.0 to 1.3

7.2 to 9.4

Rocker shaft bracket bolt

M8

×

1.25

9.81 to 19.6

1.0 to 2.0

7.2 to 14.5

Thrust plate bolt

M8

×

1.25

9.8 to 11.8

1.0 to 1.2

7.2 to 8.7

Main bearing cap bolt

M10

×

1.25

49.0 to 53.9

5.0 to 5.5

36.2 to 39.8

Connecting rod cap nut

M9

×

1.0

32.4 to 37.3

3.3 to 3.8

23.9 to 27.5

Flywheel bolt

M12

×

1.25

127 to 137

13.0 to 14.0

94.0 to 101.3

Crankshaft pulley nut

M18

×

1.5

147 to 196

15.0 to 20.0

108.5 to 144.6

Rear plate mounting bolt

M12

×

1.25

53.9 to 73.5

5.5 to 7.5

39.8 to 54.2

Equivalent to 7T

Fuel system

Hollow screw

(fuel injection pump)

M14

×

1.5

19.6 to 24.5

2.0 to 2.5

14.5 to 18.1

Delivery valve holder

(fuel injection pump)

―

39.2 to 49.0

4.0 to 5.0

28.9 to 36.1

Air bleeder plug

(fuel injection pump)

M8

×

1.25

9.81 to 13.7

1.0 to 1.4

7.2 to 10.1

Nozzle retaining nut

IDI

M16

×

0.75

34.3 to 39.2

3.5 to 4.0

25.3 to 28.9

Nozzle holder

IDI

M20

×

1.5

49.0 to 58.8

5.0 to 6.0

36.2 to 43.4

Fuel injection pipe nut

M12

×

1.5

24.5 to 34.3

2.5 to 3.5

18.1 to 25.3

Fuel leak-off pipe nut

M12

×

1.5

20.6 to 24.5

2.1 to 2.5

15.2 to 18.1

Sliding sleeve shaft

M10

×

1.25

29.4 to 41.2

3.0 to 4.2

21.7 to 30.4

Torque spring set special nut

M12

×

1.0

14.7 to 24.5

1.5 to 2.5

10.8 to 18.1

Oil system

Oil relief valve

M22

×

1.5

44.1 to 53.9

4.5 to 5.5

32.5 to 39.8

Oil pan drain plug

M14

×

1.5

34.3 to 44.1

3.5 to 4.5

25.3 to 32.5

Oil filter

M20

×

1.5

10.8 to 12.7

1.1 to 1.3

8.0 to 9.4

Oil pressure switch

PT1/8

7.85 to 11.8

0.8 to 1.2

5.8 to 8.7

Oil pan mounting bolt

M8

×

1.25

9.80 to 12.7

1.0 to 1.3

7.2 to 9.4

Equivalent to 4T

Oil strainer nut

M16

×

1.5

24.5 to 29.4

2.5 to 3.0

18.1 to 21.7

Cooling system

Thermoswitch

M16

×

1.5

18.6 to 26.5

1.9 to 2.7

13.7 to 19.6

Thermostat cover bolt

M8

×

1.25

16 to 20

1.6 to 2.0

11.8 to 14.8

Thermo case bolt

M16

×

1.5

39.2 to 49.0

4.0 to 5.0

28.9 to 36.1

Inlet and exhaust systems

Inlet cover bolt

M8

×

1.25

14.7 to 21.6

1.5 to 2.2

10.8 to 15.9

Exhaust manifold bolt

M8

×

1.25

14.7 to 21.6

1.5 to 2.2

10.8 to 15.9

Electrical system

Starter terminal B

M8

×

1.25

9.81 to 11.8

1.0 to 1.2

7.2 to 8.7

Stop solenoid fixing nut

M30

×

1.5

39.2 to 49.0

4.0 to 5.0

28.9 to 36.1

Stop solenoid blind plug

M30

×

1.5

39.2 to 49.0

4.0 to 5.0

28.9 to 36.1

Glow plug

M10

×

1.25

14.7 to 19.6

1.5 to 2.0

10.8 to 14.5

Summary of Contents for diesel engines

Page 5: ......

Page 33: ...SERVICE STANDARDS 1 20 ...

Page 34: ...1 General Tools 1 22 2 Special Tools 1 23 TOOLS LIST ...

Page 37: ...TOOLS LIST 1 24 ...

Page 41: ...OVERHAUL TIMING 1 28 ...

Page 46: ......

Page 47: ......

Page 61: ...ENGINE MAIN PARTS DISASSEMBLY 2 16 ...

Page 99: ...FUEL SYSTEM REMOVAL 3 8 ...

Page 115: ...FUEL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 3 24 ...

Page 119: ...FUEL SYSTEM INSTALLATION 3 28 2 Governor Installing the governor Installation sequence ...

Page 123: ...FUEL SYSTEM INSTALLATION 3 32 ...

Page 131: ...OIL SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 4 8 ...

Page 143: ...COOLING SYSTEM DISASSEMBLY INSPECTION AND REASSEMBLY 5 8 ...

Page 150: ......

Page 151: ......

Page 153: ...INLET AND EXHAUST SYSTEMS REMOVAL 6 4 ...

Page 159: ...INLET AND EXHAUST SYSTEMS INSTALLATION 6 10 ...

Page 160: ...1 Starter 7 2 2 Alternator 7 3 3 Stop Solenoid 7 4 4 Glow Plug 7 5 ELECTRICAL SYSTEM REMOVAL ...

Page 165: ...ELECTRICAL SYSTEM REMOVAL 7 6 ...

Page 189: ...ELECTRICAL SYSTEM INSTALLATION 7 30 ...

Page 207: ...MISCELLANEOUS 9 4 ...