MDS-E/EH Series Instruction Manual

7 Troubleshooting

394

IB-1501229-F

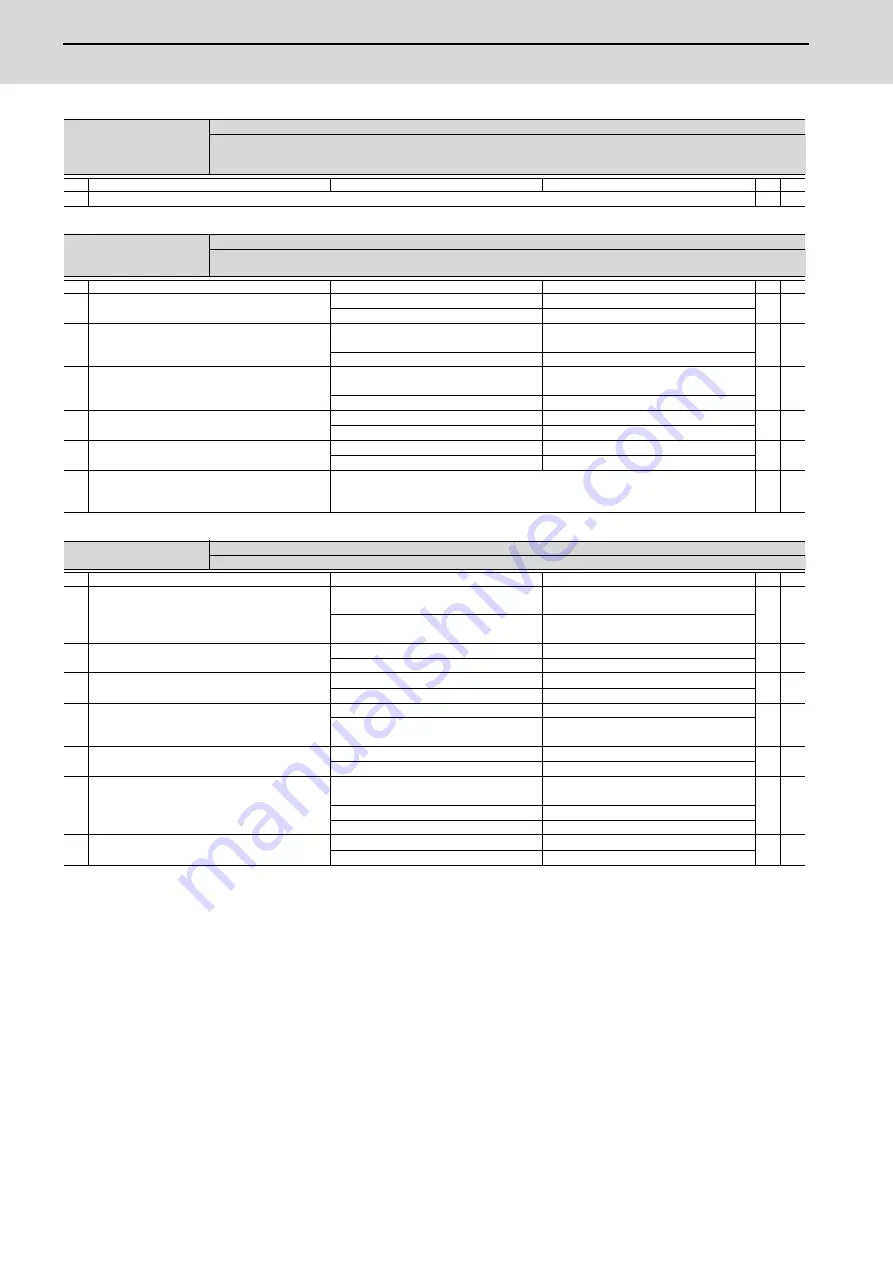

Alarm No.

2E

Main side encoder: Error 4

The motor side encoder (CN2 side) detected an error.

(Note) It includes the linear scale in the case of linear motor.

As details differ for each encoder, refer to section "Encoder alarm".

Investigation details

Investigation results

Remedies

SV SP

1

Check the alarm No. "1B" items.

◯

◯

Alarm No.

2F

Main side encoder: Communication error

An error was detected in communication data with the motor side encoder or with the linear scale of a linear servo system. Or the

communication was interrupted.

Investigation details

Investigation results

Remedies

SV SP

1

Jiggle the encoder connectors (drive unit side and

encoder side) and check if they are disconnected.

The connector is disconnected (or loose).

Correctly install.

◯

◯

The connector is not disconnected.

Check the investigation item No. 2.

2

Is the encoder cable wired in the same conduit as

the motor's power cable, or are the two cables laid

in parallel near each other?

The cables are wired near each other. (Noise

is entering from the power cable.)

Improve the cable wiring.

◯

◯

The wires are sufficiently separated.

Check the investigation item No. 3.

3

Is the motor FG wire connected only to the drive unit

which drives it?

(Is the motor grounded to one point?)

The motor FG wire is grounded on the motor

side.

Ground the motor to one point, connecting

the wires together on the drive unit side.

◯

◯

The motor is grounded to one point.

Check the investigation item No. 4.

4

Turn the power OFF, and check the encoder cable

connection with a tester. (Is the cable shielded?)

The connection is faulty.

Replace the encoder cable.

◯

◯

The connection is normal.

Check the investigation item No. 5.

5

Replace with another unit, and check whether the

fault is on the unit side or encoder side.

The alarm is on the drive unit side.

Replace the drive unit.

◯

◯

The alarm is on the encoder side.

Check the investigation item No. 6.

6

Check if there is any abnormality in the encoder's

ambient environment.

(Ex. Ambient temperature, noise, grounding)

Take remedies according to the causes of the abnormality in the ambient environment.

◯

◯

Alarm No.

30

Over regeneration:

Over-regeneration detection level became over 100%. The regenerative resistor is overloaded.

Investigation details

Investigation results

Remedies

SV SP

1

Check if the regenerative capacity exceeds the

regenerative resistor tolerable capacity.

The regenerative capacity exceeds the

regenerative resistor tolerable capacity.

Add the option regenerative resistor or

replace it.

◯

◯

The regenerative resistor selection is

appropriate.

Check the investigation item No. 2.

2

Check if the parameter is set incorrectly, and check

the values of sv036 and sp032.

The parameters are set incorrectly.

Change the parameters.

◯

◯

The parameters are correct.

Check the investigation item No. 3.

3

Is an external regenerative resistor used?

An external regenerative resistor is used.

Check the investigation item No. 5.

◯

A built-in regenerative resistor is used.

Check the investigation item No. 4.

4

Is the short wire connected between P and D

terminal? Are there any problems with the

connection condition?

The wire is not connected.

Connect the wire.

◯

The connector is disconnected.

The connector has a contact fault.

Reconnect the connector.

Replace the connector.

5

Is the connection of the regenerative resistor or

regeneration resistor cable correct?

The connection is incorrect.

Rewire.

◯

◯

The connection is correct.

Check the investigation item No. 6.

6

Is the regeneration resistor or the regeneration

resistor cable broken? Disconnect the regenerative

resistor terminal and check the resistance value

with a tester.

The regeneration resistor is broken. Or the

resistance value is large.

Replace the regenerative resistor.

◯

◯

The regeneration resistor cable is broken.

Replace the cable.

The resistance value is normal.

Check the investigation item No. 7.

7

Check if the power supply voltage is too high.

The power supply voltage exceeded 253V.

Review the power supply.

◯

◯

The power supply voltage is normal.

Replace the drive unit.

Summary of Contents for MDS-E

Page 1: ......

Page 3: ......

Page 15: ......

Page 17: ......

Page 19: ......

Page 21: ......

Page 31: ......

Page 32: ...1 IB 1501229 F 1 Installation ...

Page 76: ...45 IB 1501229 F 2 Wiring and Connection ...

Page 132: ...101 IB 1501229 F 3 Safety Function ...

Page 142: ...111 IB 1501229 F 4 Setup ...

Page 277: ...MDS E EH Series Instruction Manual 4 Setup 246 IB 1501229 F ...

Page 278: ...247 IB 1501229 F 5 Servo Adjustment ...

Page 351: ...MDS E EH Series Instruction Manual 5 Servo Adjustment 320 IB 1501229 F ...

Page 352: ...321 IB 1501229 F 6 Spindle Adjustment ...

Page 404: ...373 IB 1501229 F 7 Troubleshooting ...

Page 455: ...MDS E EH Series Instruction Manual 7 Troubleshooting 424 IB 1501229 F ...

Page 456: ...425 IB 1501229 F 8 Maintenance ...

Page 475: ...MDS E EH Series Instruction Manual 8 Maintenance 444 IB 1501229 F ...

Page 476: ...445 IB 1501229 F 9 Power Backup System ...

Page 494: ...463 IB 1501229 F 10 Appx 1 Cable and Connector Assembly ...

Page 504: ...473 IB 1501229 F 11 Appx 2 D A Output Specifications for Drive Unit ...

Page 514: ...483 IB 1501229 F 12 Appx 3 Protection Function ...

Page 523: ...MDS E EH Series Instruction Manual 12 Appx 3 Protection Function 492 IB 1501229 F ...

Page 524: ...493 IB 1501229 F 13 Appx 4 Compliance to EC Directives ...

Page 528: ...497 IB 1501229 F 14 Appx 5 EMC Installation Guidelines ...

Page 540: ...509 IB 1501229 F 15 Appx 6 Higher Harmonic Suppression Measure Guidelines ...

Page 550: ......

Page 554: ......