1

OV

ER

VI

EW

2

SY

STEM

CONFIGURA

TION

3

SP

ECI

F

IC

A

T

IO

NS

4

PA

R

T

S

N

A

M

E

5

UL,

cU

L

ST

A

N

D

AR

D

S AN

D

E

MC DIRECTIV

E

6

OPT

ION

7

INS

TAL

LA

T

IO

N

8

COMMUNICA

TION

CABL

E

3. SPECIFICATIONS

3.2 Performance Specifications

3 - 3

*1

Bright dots (always lit) and dark dots (unlit) may appear on a liquid crystal display panel due to its characteristics. It is impossible

to completely avoid this symptom, as the liquid crystal display comprises of a great number of display elements. Flickers may be

observed depending on the display color.

Please note that these dots appear due to its characteristic and are not caused by product defect.

Flickers and partial discoloration may be generated on the liquid crystal display panel due to the display contents or the contrast

adjustment. However, please note that these phenomena appear due to its characteristic and are not caused by product defect.

There is a difference in the display brightness and the color tones between liquid crystal display panels. When using multiple

liquid crystal display panels, please note that there is an individual difference between them.

A crosstalk (shadow as an extension of the display) may appear on the liquid crystal display panel. Please note hat it appears due

to its characteristic.

When the display section is seen from the outside of the display angle, the display color seems like it has changed. Please note

that it is due to its characteristic.

Please note that the response time, brightness and color of the liquid crystal display panel may vary depending on the usage

environmental temperature.

(Especially, the response time of liquid crystal display is slower in the lower temperature due to its characteristic. Please use the

display after checking the response time.)

When the same screen is displayed for a long time, an incidental color or partial discoloration is generated on the screen due to

heat damage, and it may not disappear.

To prevent the heat damage, the screen saver function is effective.

For details on the screen saver function, refer to the following.

Just after the GOT is powered off, sometimes an image lag or partial discoloration is generated temporary. However they are

caused by the characteristic of the liquid crystal. (After powering off, they disappear within a few minutes.)

*2

Gradation inversion is a characteristic of liquid crystal displays. Please be forewarned that depending on the displayed color, the

visualization may be difficult even within the described view angle.

*3

The GOT screen saving/backlight off function prevents images from becoming permanently etched on the display screen and

increases the backlight life.

*4

The touch panel is analog resistive film-type. If you touch the panel simultaneously in 2 points or more, the switch that is located

around the center of the touched point, if any, may operate. Do not touch the panel in 2 points or more simultaneously.

Do not press the GOT display section with a pointed material as a pen or driver. Doing so can result in a damage or failure of the

display section.

An analog resistive film-type touch panel does not require adjustment usually. However, misalignment between object position

and actual touched position may be caused as usage time passes. If misalignment between object position and actual touched

position may occur, adjust the touch panel position. Misalignment between object position and actual touched position may

operate an unintended object, which causes unintended operation by mis-output and mis-operation.

*5

ROM in which new data can be written without deleting the written data.

*6

Note that this does not guarantee all user's operation environment. The protection is not applied when the interface environment

protection cover is removed.

In addition, the product may not be used in environments under exposition of oil or chemicals for a long period of time, or in

environments filled with oil-mist.

*7

The USB cable that connects the GOT and a personal computer is connected to the USB interface (device) in the interface

environmental protection cover of the GOT. Since the Handy GOT is used with the interface environment protection cover opened,

it is out of the warranty for protective structure (IP65F).

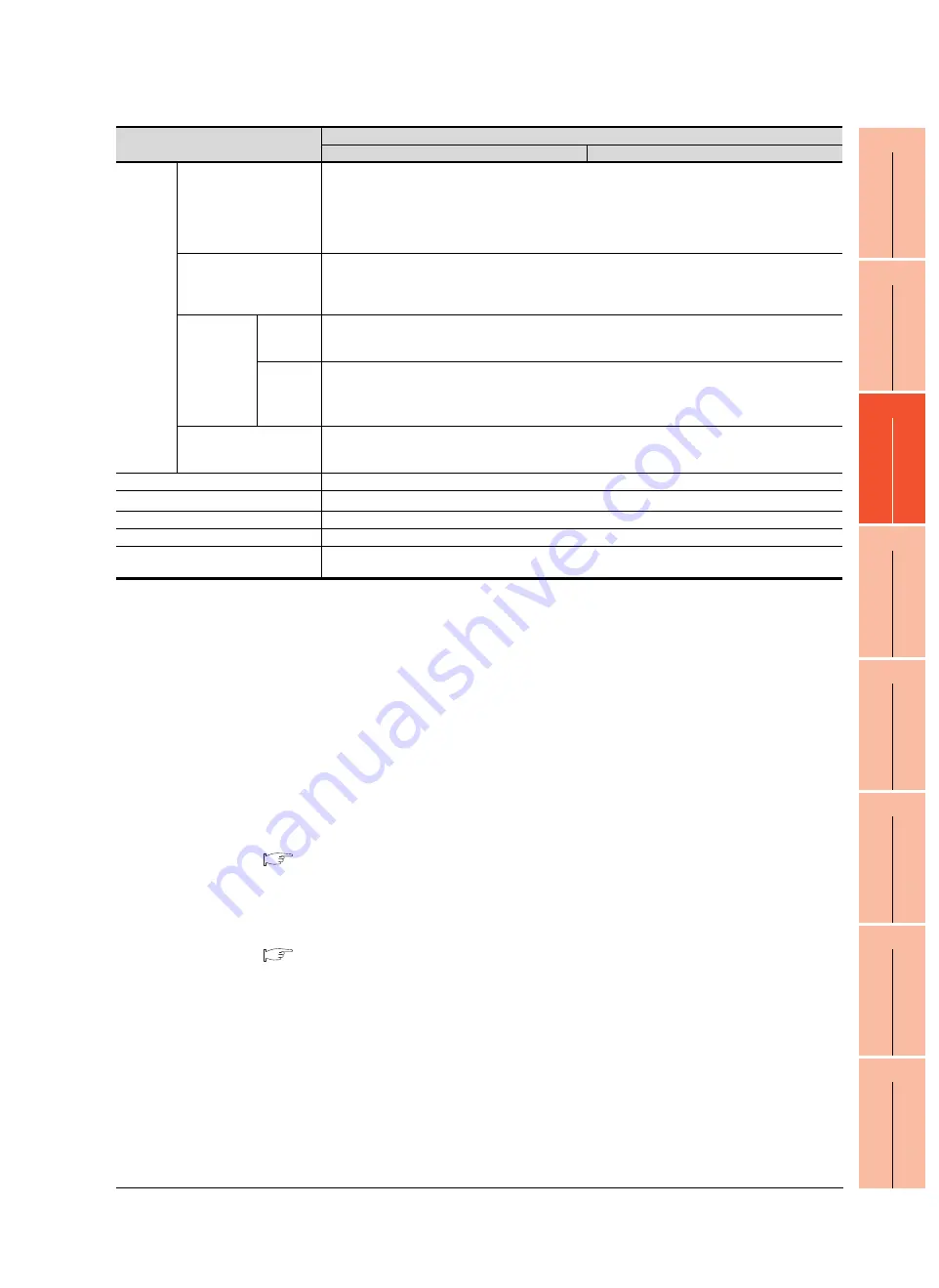

Built-in

interface

RS-232

RS-422

RS-232, RS-422/485, 1ch each (When you use, select any of channels including Ethernet. Ethernet

is set at factory shipment.)

Transmission speed: 115200/57600/38400/19200/9600/4800bps

Connector shape: Round type 32pins (Male)

Application: For communicating with a controller

Terminating resistor: 330

Ω

(Fixed)

Ethernet

Data transfer method: 100BASE-TX, 10BASE-T, 1ch

Connector shape: Round type 32pins (Male)

Application: For communicating with a controller, or using the gateway function, connecting a PC

(project data upload/download, OS installation, FA transparent function)

USB

Host

USB(Full Speed 12Mbps), Host, 1ch

Connector shape: TYPE-A

Application: Data transfer, data storage

Device

USB(Full Speed 12Mbps), device 1ch

Connector shape: Mini-B

Application: For connecting a personal computer (Project data upload/download, OS installation, FA

transparent function

*7

)

SD card

SD standard, 1ch

Supported memory card: SDHC memory card, SD memory card

Application: For uploading/downloading project data, OS installation, storing logging data

Buzzer output

Single tone (tone length adjustable)

Protective structure

*6

IP65f (valid when the external cable is connected, except for the connector conversion box side)

External dimensions

145 (W) × 185 (H) × 79.3 (D) [mm]

Weight

Approx. 0.79kg (GT14 Handy main unit only)

Compatible software package

(GT Designer3 version)

Version1.71Z or later

Item

Specifications

GT1455HS-QTBDE

GT1450HS-QMBDE

Summary of Contents for GT14

Page 1: ......

Page 2: ......

Page 34: ...A 32 ...

Page 46: ...1 4 1 OVERVIEW 1 1 Features ...

Page 60: ...3 6 3 SPECIFICATIONS 3 4 Battery specifications ...

Page 72: ...5 8 5 UL cUL STANDARDS AND EMC DIRECTIVE 5 2 EMC Directive ...

Page 108: ...6 36 6 OPTION 6 7 With wall mounting Attachment ...

Page 124: ...8 10 8 COMMUNICATION CABLE 8 2 External Cable Relay Cable ...

Page 172: ...11 16 11 COMMUNICATION INTERFACE SETTING COMMUNICATION SETTING 11 3 Ethernet Setting ...

Page 200: ...12 28 12 DISPLAY AND OPERATION SETTINGS GOT SET UP 12 6 License Management ...

Page 296: ...14 92 14 FILE DISPLAY AND COPY PROGRAM DATA CONTROL 14 2 Various Data Control ...

Page 320: ...15 24 15 GOT SELF CHECK DEBUG AND SELF CHECK 15 4 GOT start time ...

Page 322: ...16 2 16 CLEANING DISPLAY SECTION CLEAN ...

Page 336: ...17 14 17 INSTALLATION OF COREOS BOOTOS AND STANDARD MONITOR OS 17 5 CoreOS ...

Page 360: ...19 8 19 MAINTENANCE AND INSPECTION 19 5 Backlight Shutoff Detection ...

Page 382: ......

Page 450: ...22 34 22 COMPUTER LINK CONNECTION 22 6 Precautions ...

Page 508: ...23 58 23 ETHERNET CONNECTION 23 5 Precautions ...

Page 526: ......

Page 592: ...26 22 26 SERVO AMPLIFIER CONNECTION 26 7 Precautions ...

Page 598: ...27 6 27 ROBOT CONTROLLER CONNECTION 27 6 Precautions ...

Page 607: ...MULTIPLE GOT CONNECTION FUNCTION 29 MULTIPLE GOT CONNECTION FUNCTION 29 1 ...

Page 608: ......

Page 619: ...MULTI CHANNEL FUNCTION 30 MULTI CHANNEL FUNCTION 30 1 ...

Page 620: ......

Page 635: ...FA TRANSPARENT FUNCTION 31 FA TRANSPARENT FUNCTION 31 1 ...

Page 636: ......

Page 688: ...31 52 31 FA TRANSPARENT FUNCTION 31 7 Precautions ...

Page 698: ...App 10 APPENDICES Appendix 2 Usage Condition of Utility Function ...

Page 703: ......

Page 704: ......

Page 705: ......

Page 706: ......

Page 738: ...A 32 ...

Page 748: ......

Page 820: ...33 44 33 CONNECTION TO OMRON PLC 33 4 Device Range that Can Be Set ...

Page 834: ...34 14 34 CONNECTION TO OMRON TEMPERATURE CONTROLLER 34 7 Precautions ...

Page 912: ...37 22 37 CONNECTION TO JTEKT PLC 37 7 Precautions ...

Page 930: ...38 18 38 CONNECTION TO SHARP PLC 38 6 Device Range that Can Be Set ...

Page 980: ...41 16 41 CONNECTION TO TOSHIBA PLC 41 4 Device Range that Can Be Set ...

Page 996: ...43 8 43 CONNECTION TO PANASONIC SERVO AMPLIFIER 43 7 Precautions ...

Page 1052: ...46 10 46 CONNECTION TO HITACHI PLC 46 6 Device Range that Can Be Set ...

Page 1092: ...47 40 47 CONNECTION TO FUJI PLC 47 5 Precautions ...

Page 1108: ...48 16 48 CONNECTION TO FUJI TEMPERATURE CONTROLLER 48 7 Precautions ...

Page 1142: ...49 34 49 CONNECTION TO YASKAWA PLC 49 4 Device Range that Can Be Set ...

Page 1332: ...55 28 55 CONNECTION TO GE PLC 55 7 Precautions ...

Page 1348: ...56 16 56 CONNECTION TO LS INDUSTRIAL SYSTEMS PLC 56 6 Device Range that Can Be Set ...

Page 1352: ...57 4 57 CONNECTION TO SICK SAFETY CONTROLLER 57 5 Device Range that Can Be Set ...

Page 1368: ...58 16 58 CONNECTION TO SIEMENS PLC 58 4 Device Range that Can Be Set ...

Page 1370: ...59 2 59 CONNECTION TO HIRATA CORPORATION HNC CONTROLLER ...

Page 1372: ...60 2 60 CONNECTION TO MURATEC CONTROLLER ...

Page 1374: ......

Page 1515: ...MODBUS CONNECTIONS 63 MODBUS R RTU CONNECTION 63 1 64 MODBUS R TCP CONNECTION 64 1 ...

Page 1516: ......

Page 1537: ...CONNECTIONS TO PERIPHERAL EQUIPMENT 65 VNC R SERVER CONNECTION 65 1 ...

Page 1538: ......

Page 1545: ......

Page 1546: ......