17

INST

ALLA

TION O

F

CO

REOS

, BO

OT

O

S AND

ST

AND

ARD M

O

NIT

O

R OS

18

DRA

WING

SO

FTW

A

RE

SE

TTI

N

GS

19

MAINTENANCE AND

INS

P

E

CT

IO

N

20

T

ROUBL

ESHOOTI

NG

21

DIRECT

CONNECTION

T

O

CP

U

22

CO

M

P

U

T

E

R

L

INK

C

O

NNECTION

23

ETHERNET

CONNECTION

24

CC-Link

CONNECTION

(V

ia G

4)

23. ETHERNET CONNECTION

23.4 PLC Side Setting

23 - 53

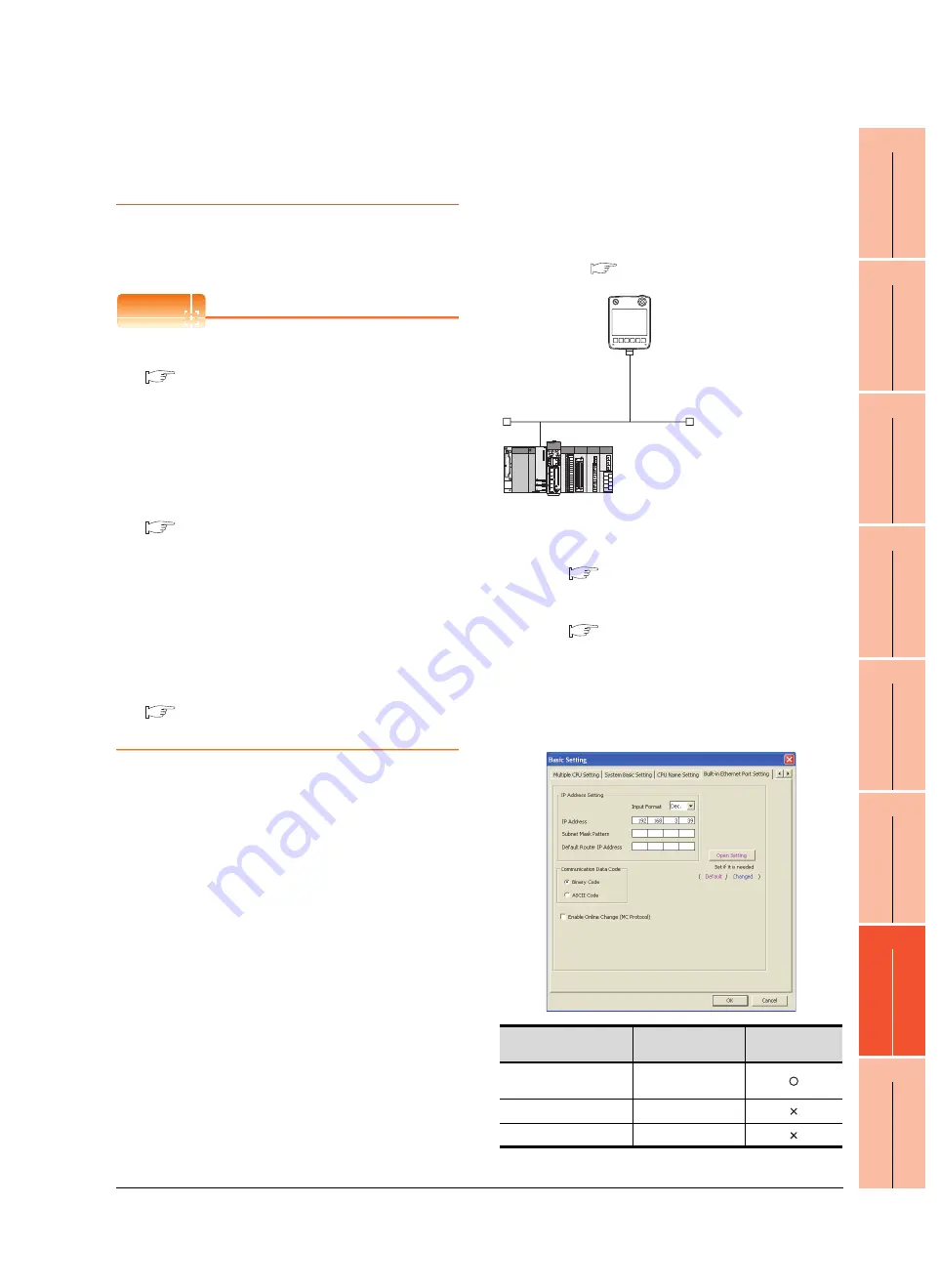

23.4.15 Connecting to PERIPHERAL I/

F (Built-in Ethernet port Motion

Controller CPU)

This section describes the settings of the GOT and Built-in

Ethernet port motion controller CPU in the following case of

system configuration.

POINT

POINT

POINT

(1) GOT type setting

For details, refer to the following.

GOT1000 Series Connection Manual for GT

Works3

1.1.1 Setting connected equipment (Channel

setting)

(2) Setting [Controller Type]

(2) CPU No. specification of Q170MCPU

Set whether to monitor the PLC CPU area or the

Motion CPU area of Q170MCPU, in the CPU No.

specification. For details, refer to the following.

(3) PLC type of GX Works2/GX Developer

When creating a program, set the following PLC

type:

• For Q173D(S)CPU/Q172D(S)CPU

QnUD(E)(H)CPU

• For Q170MCPU

Q03UDCPU

(4) Built-in Ethernet port CPU

For details of Built-in Ethernet port CPU, refer to

the following manual.

User's Manual of Q173D(S)CPU/

Q172D(S)CPU, and Q170MCPU

System configuration

Leave the Built-in Ethernet port Motion Controller CPU

settings as default in the following system

configuration. Set [Ethernet] for [Controller Setting] on

GT Designer3, and then connect Built-in Ethernet port

QCPU to the GOT.

*1

For the settings when using system devices including a hub

and a transceiver, refer to the following.

23.4.6 Connecting to Built-in Ethernet port CPU

(multiple connection)

*2

These setting items do not exist on the PLC side. However,

the virtual values must be set on the GOT side.

[Controller Setting] and [Ethernet] of GT

Basic setting of MT Works2

Use the default values of the basic setting for the system

configuration above.

(1) Built-in Ethernet Port Setting

Item

Set value

Setting necessity

at GOT connection

IP Address

192.168.3.39

(Default)

Subnet Mask Pattern

-

Default Router IP Address

-

<GOT>

(The settings other than the

following are set to the default)

*1

*2

*2

Network No.

: 1

PLC No.

: 1

IP address

: 192.168.3.1

Port No.

: 5001

Communication

format

: UDP (fixed)

Network No.

: 1 (virtual)

PLC No.

: 2 (virtual)

IP address

: 192.168.3.39

Open system

: MELSOFT connection (fixed)

<Connecting to Built-in Ethernet port CPU>

(The following settings are set to the default)

[Controller Setting] and [Ethernet] of GT Designer3

Summary of Contents for GT14

Page 1: ......

Page 2: ......

Page 34: ...A 32 ...

Page 46: ...1 4 1 OVERVIEW 1 1 Features ...

Page 60: ...3 6 3 SPECIFICATIONS 3 4 Battery specifications ...

Page 72: ...5 8 5 UL cUL STANDARDS AND EMC DIRECTIVE 5 2 EMC Directive ...

Page 108: ...6 36 6 OPTION 6 7 With wall mounting Attachment ...

Page 124: ...8 10 8 COMMUNICATION CABLE 8 2 External Cable Relay Cable ...

Page 172: ...11 16 11 COMMUNICATION INTERFACE SETTING COMMUNICATION SETTING 11 3 Ethernet Setting ...

Page 200: ...12 28 12 DISPLAY AND OPERATION SETTINGS GOT SET UP 12 6 License Management ...

Page 296: ...14 92 14 FILE DISPLAY AND COPY PROGRAM DATA CONTROL 14 2 Various Data Control ...

Page 320: ...15 24 15 GOT SELF CHECK DEBUG AND SELF CHECK 15 4 GOT start time ...

Page 322: ...16 2 16 CLEANING DISPLAY SECTION CLEAN ...

Page 336: ...17 14 17 INSTALLATION OF COREOS BOOTOS AND STANDARD MONITOR OS 17 5 CoreOS ...

Page 360: ...19 8 19 MAINTENANCE AND INSPECTION 19 5 Backlight Shutoff Detection ...

Page 382: ......

Page 450: ...22 34 22 COMPUTER LINK CONNECTION 22 6 Precautions ...

Page 508: ...23 58 23 ETHERNET CONNECTION 23 5 Precautions ...

Page 526: ......

Page 592: ...26 22 26 SERVO AMPLIFIER CONNECTION 26 7 Precautions ...

Page 598: ...27 6 27 ROBOT CONTROLLER CONNECTION 27 6 Precautions ...

Page 607: ...MULTIPLE GOT CONNECTION FUNCTION 29 MULTIPLE GOT CONNECTION FUNCTION 29 1 ...

Page 608: ......

Page 619: ...MULTI CHANNEL FUNCTION 30 MULTI CHANNEL FUNCTION 30 1 ...

Page 620: ......

Page 635: ...FA TRANSPARENT FUNCTION 31 FA TRANSPARENT FUNCTION 31 1 ...

Page 636: ......

Page 688: ...31 52 31 FA TRANSPARENT FUNCTION 31 7 Precautions ...

Page 698: ...App 10 APPENDICES Appendix 2 Usage Condition of Utility Function ...

Page 703: ......

Page 704: ......

Page 705: ......

Page 706: ......

Page 738: ...A 32 ...

Page 748: ......

Page 820: ...33 44 33 CONNECTION TO OMRON PLC 33 4 Device Range that Can Be Set ...

Page 834: ...34 14 34 CONNECTION TO OMRON TEMPERATURE CONTROLLER 34 7 Precautions ...

Page 912: ...37 22 37 CONNECTION TO JTEKT PLC 37 7 Precautions ...

Page 930: ...38 18 38 CONNECTION TO SHARP PLC 38 6 Device Range that Can Be Set ...

Page 980: ...41 16 41 CONNECTION TO TOSHIBA PLC 41 4 Device Range that Can Be Set ...

Page 996: ...43 8 43 CONNECTION TO PANASONIC SERVO AMPLIFIER 43 7 Precautions ...

Page 1052: ...46 10 46 CONNECTION TO HITACHI PLC 46 6 Device Range that Can Be Set ...

Page 1092: ...47 40 47 CONNECTION TO FUJI PLC 47 5 Precautions ...

Page 1108: ...48 16 48 CONNECTION TO FUJI TEMPERATURE CONTROLLER 48 7 Precautions ...

Page 1142: ...49 34 49 CONNECTION TO YASKAWA PLC 49 4 Device Range that Can Be Set ...

Page 1332: ...55 28 55 CONNECTION TO GE PLC 55 7 Precautions ...

Page 1348: ...56 16 56 CONNECTION TO LS INDUSTRIAL SYSTEMS PLC 56 6 Device Range that Can Be Set ...

Page 1352: ...57 4 57 CONNECTION TO SICK SAFETY CONTROLLER 57 5 Device Range that Can Be Set ...

Page 1368: ...58 16 58 CONNECTION TO SIEMENS PLC 58 4 Device Range that Can Be Set ...

Page 1370: ...59 2 59 CONNECTION TO HIRATA CORPORATION HNC CONTROLLER ...

Page 1372: ...60 2 60 CONNECTION TO MURATEC CONTROLLER ...

Page 1374: ......

Page 1515: ...MODBUS CONNECTIONS 63 MODBUS R RTU CONNECTION 63 1 64 MODBUS R TCP CONNECTION 64 1 ...

Page 1516: ......

Page 1537: ...CONNECTIONS TO PERIPHERAL EQUIPMENT 65 VNC R SERVER CONNECTION 65 1 ...

Page 1538: ......

Page 1545: ......

Page 1546: ......