226

Paper Problems

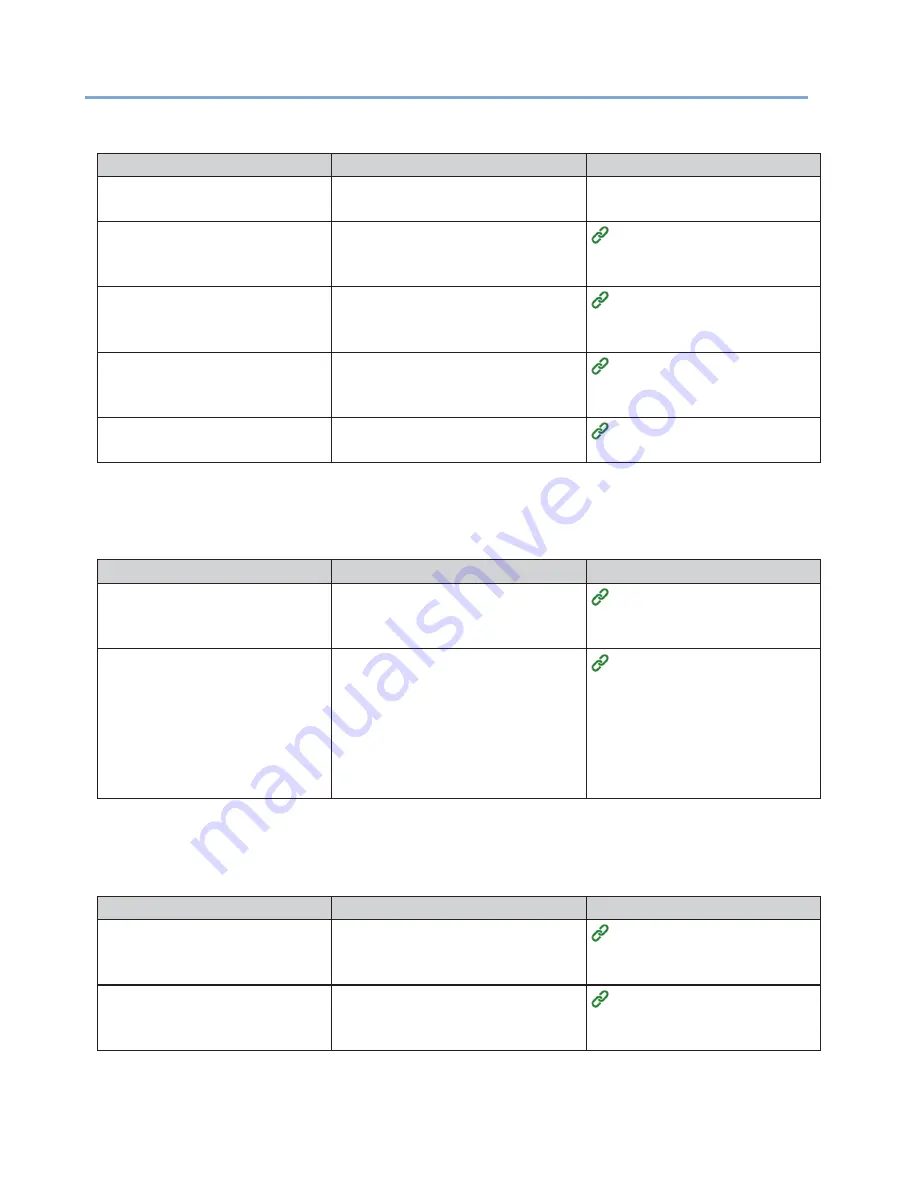

Paper Jams Frequently Occur/The Paper Is Pulled in at an Angle

Cause

Remedy

Reference

The machine is not level.

Install the machine in a flat and

stable location.

-

The paper is too light or too

heavy.

The paper is too light or too heavy.

Use paper that is suitable for the

machine.

Loading Paper

The paper contains humidity or

has an electrostatic charge.

Use paper that is stored in

an environment with suitable

temperature and humidity.

Loading Paper

The paper is wrinkled or warped.

Use paper that is suitable for the

machine. If the paper is warped, fix

it.

Loading Paper

The paper is not loaded straight.

Align the paper guide with the paper.

Loading Paper

The Machine Does Not Recover When the Paper Jam Is Removed

Cause

Remedy

Reference

The machine may not recover

unless the top cover or feeder

cover is opened and closed.

Open and close the top cover or

feeder cover.

Names of Components

The combination of the cut type

setting and paper sensor position

of the machine does not match.

Change the position of the top

sensor and bottom sensor so that

they do not overlap if their positions

were matching.

Change the position of the top sensor

and bottom sensor so that they

match if they were not overlapping.

Setting the Paper Sensors

The Paper Curls/The Paper Wrinkles

Cause

Remedy

Reference

The paper contains humidity or

has an electrostatic charge.

Use paper that is stored in

an environment with suitable

temperature and humidity.

Loading Paper

Light paper is being used.

Set [MENUS] > [FEEDER CONFIG]

> [MEDIAWEIGHT] to a lighter value

on the operation panel.

Loading Paper

Summary of Contents for 360C

Page 1: ...360C Operator s Manual 880076 0101 Rev 2 ...

Page 17: ...17 Unpacking How to Unpack the Machine Checking the Accessories Installing Consumables 2 ...

Page 24: ...24 ...

Page 36: ...35 7 Tighten the screws x 2 8 Connect the connector ...

Page 37: ...36 9 Attach the Cover Cable PSNT 10 Attach the Cap Cover PSNT x 2 ...

Page 50: ...49 ...

Page 91: ...90 ...

Page 147: ...146 ...

Page 156: ...155 8 Remove the cover toner 9 Close the top cover 10 Open the toner cartridge cover ...

Page 167: ...166 8 Close the top cover ...

Page 178: ...177 15 Close the feeder cover until it clicks ...

Page 179: ...178 ...

Page 198: ...197 4 Close the feeder cover until it clicks ...

Page 233: ...232 ...

Page 244: ...243 The settings of the machine can be changed from the Admin Setup tab ...

Page 280: ...279 11 Confirm the setting results and click Back ...

Page 289: ...288 ...

Page 296: ......

Page 297: ......