Chapter 7

Appendix

201

7.2 Stopping method and Recovery

7.2.1 Stopping method

Actuator operation can be stopped in two methods: normal operation stop and emergency

stop.

1) Normal operation stop

Normal position control is active: Set a deceleration operation plan and cause the

actuator to decelerate to a stop, according to the plan,

under normal position control

2) Emergency stop (stop with immediate servo-OFF)

Cancel the operation plan and immediately turn OFF the servo (power supply to the motor

is cut off).

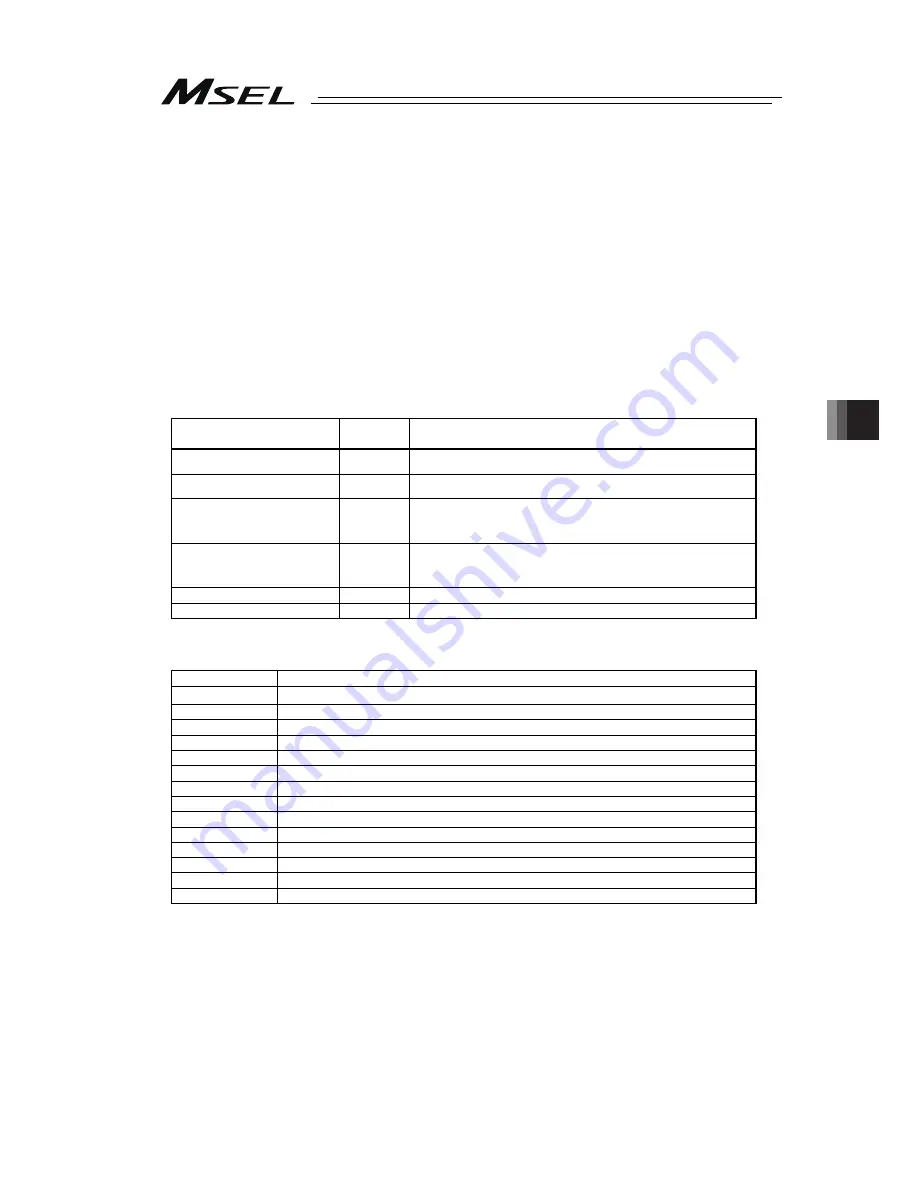

How operation is stopped in each condition is explained below.

Stop command,

Condition

Stopping

method

Remarks

Pause

1)

Servo OFF

1)

Emergency stop

1)

Since the motor drive source is cut off by hardware means,

the deceleration operation plan may have to be forcibly

stopped beforehand.

SEL program command

1)

Stop is made when the following four commands are

issued.

HOLD, CANC, STOP, ABPG

Errors not described in list

1)

Errors in list

2)

Error of stop with immediate servo OFF in 2)

Error No.

Error name

614

Driver synchronizing communication LRC error

6BB

Deviation overflow error (home return not yet complete)

6BC

Stop deviation overflow error (home return not yet complete)

B05

Estimate stroke exceeded during home return

B11

Home position sensor escape timeout error

C6B

Deviation overflow error

C99

Home position undetected error

CA5

Stop deviation overflow error

CC6

Driver error initial detection

D0A

Driver overload error

D10

IPM error (POE0)

D15

Driver CPU down status error

D17

Main CPU alarm status error

F00 to FBF

All system-down level errors

Summary of Contents for MSEL

Page 1: ...MSEL Controller Instruction Manual Fifth Edition ...

Page 2: ......

Page 4: ......

Page 30: ...22 ...

Page 44: ...Chapter 1 Specifications Check 36 ...

Page 102: ...Chapter 4 Home Return Absolute Reset 94 ...

Page 232: ......

Page 233: ......