●

Print head air purge 3-1

3.1 Print head air purge

If the makeup remains in the electrode section after cleaning or if you use the IJ

printer at a high humidity, moisture condensation may occur within the print head,

causing leakage from the deflection electrode section. It is also important to

remember that dust or splashed ink accumulation on the deflection electrode

section may cause leakage. Performing the following air purge procedure for the

print head interior is effective in preventing such leakage.

3. INSTALLATION CHECK ITEMS

If the air-purge amount is excessive, print irregularities may occur.

After air-purge pressure adjustment, be sure to perform a printing test to

verify the printing results.

(1) Situations requiring an air purge

When the printer is used in a highly humid place such as a beer or other beverage can line

(If you use the printer in an environment in which the relative humidity is 85% or higher,

complete the print head air-purge procedure).

When a water drainage blow sequence is performed before printing.

When the printer is used in a place where a considerable amount of paper powder or other dust

exists.

When the printing distance is short so that the end of the print head is splashed with ink.

When you use inks that are indicated on the handling guidance of each ink to complete

air-purge procedure.

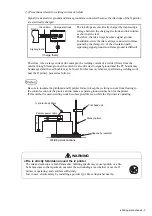

(2) Air-purging procedure

Introduce clean dry air into the print head air purge connection port (Rc 1/8 (PT 1/8)×screw) in

the rear of the printer main body at a pressure of about 0.1 to 0.3 MPa. If it is possible that the

employed air tanks oil or water, turn it into clean dry air with an air filter, micro-mist separator, or

the like before introducing it into the printer main body.

1

2

3

4

5

NOTICE

Max. tightening torque:1.5N m

Back of body

Print head air purge

connection port

Made of resin. Be careful not to

tighten too tightly when connecting

with a metal joint.

Air source

(clean dry air)

(capacity: Approx. 1L/min)

Pressure reducing valve

Pressure gauge

0.1

0.3MPa

~

・