●

Input/output (I/O) specifications 4-16

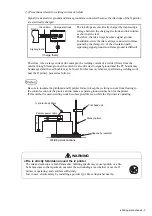

t1 5μs min.(f=200 kHz max)

t2

OFF

ON

Duty

t2

t1

×100

%

=

See that the duty is between 30% and 70%.

Encoder signal

t3 2 μs min.

ON

Flat period of encoder signal (t3) : 2 μs min.

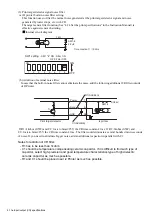

Encoder

Diameter

Conveyor

(5) When a rotary encoder is used, the print character width cannot be changed by changing the IJ printer character

width set value.

When the print character width must be changed, a device (timing belt, pulley, etc.) which varies the conveyor

speed and rotary encoder speed synch signal pulse frequency ratio must be installed.

(6) Restriction of the speed synchronization signal pulse frequency from the rotary encoder

(7) Rotary encoder selection method and calculation method

The print character width when the product speed matching function is used is determined by the amount of

movement of the product per encoder pulse.

Several examples are introduced below.

Example 1: Calculate the resolution of the rotary encoder when the rotary encoder is connected directly to the

conveyor shaft.

<Calculation conditions>

●

Dot font

: 5

×

7 dots (horizontal direction 5, vertical direction 7)

●

Inter-character space

: 1 dot (1 scan)

●

Inter-character interval

: 1.8mm [horizontal direction 6 dots (6 scans)]

(Inter-character dots 5 + inter-characters space 1)

●

Diameter of conveyor pulley : 60mm

Distance the conveyor moves per 1 revolution of the rotary encoder

60mm

×

3.14=188.4mm/rev

Number of scans which must be executed while the conveyor is moving 1mm

6 scans/1.8mm=3.33 scans/mm

Required resolution of the rotary encoder (number of output pulses per 1 revolution of

the rotary encoder)

188.4mm/rev

×

3.33 scans/mm=628PPR ( 2500PPR, Division factor=4)

1

2

3

=

.

.

Arrange for encoder signal cycle time (t1) to be at least 5

μ

s.