4-17

●

Input/output (I/O) specifications

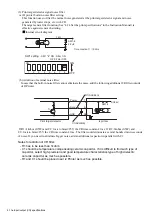

Pulley B

Encoder

Conveyor

Diameter

Pulley A

Example 2: Calculate the diameter ratio (RT) of the pulley when the rotary encoder is connected to the

conveyor through a pair of pulleys.

<Calculation conditions>

●

Dot font

: 5

×

7 dots (horizontal direction 5, vertical direction 7)

●

Inter-character space

: 1 dot (1 scan)

●

Inter-character interval

: 1.8mm [horizontal direction 6 dots (6 scans)]

(inter-character dots 5 + inter-character space 1)

●

Diameter of conveyor pulley : 60mm

●

Resolution of rotary encoder : 1,000PPR

Amount of movement of conveyor per 1 revolution of rotary encoder

60mm

×

3.14=188.4mm/rev

Number of scans which must be executed while conveyor moves 1mm

6 scans/1.8mm=3.33 scans/mm

Necessary number of output pulses (resolution) from rotary encoder

188.4mm/rev

×

3.33 scans/mm=628PPR

Diameter ratio (RT) of pulley

RT=Diameter of pulley B/diameter of pulley A=1,000PPR/628PPR=Approx. 1.6/1

1

2

3

4

Pulley

Diameter

Encoder

Conveyer

Example 3: Calculate the necessary rotary encoder resolution when a pulley is installed to the shaft of the

rotary encoder and this pulley is connected to the conveyor.

<Calculation conditions>

●

Dot font

: 5

×

7 dots (horizontal direction 5, vertical direction 7)

●

Inter-character space

: 1 dot (1 scan)

●

Inter-character interval

: 1.8mm [horizontal direction 6 dots (6 scans)]

(Inter-character dots 5 + inter-character space 1)

●

Diameter of rotary encoder pulley : 95.5mm

Amount of movement of conveyor per 1 revolution of rotary encoder

95.5mm

×

3.14=300mm/rev

Number of scans which must be executed while the conveyor is moving 1mm

6 scans/1.8mm=3.33 scans/mm

Necessary number of output pulses (resolution) from rotary encoder

300mm/rev

×

3.33 scans/mm=1,000PPR

1

2

3