Chapter 7 Explanation of Functions

7 - 33

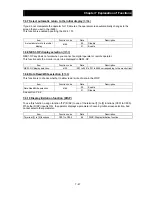

7.5.17 V/f gain setting

[A045/A245]

The V/f gain setting function allows you to change the inverter output voltage by specifying the rate of the

output voltage to the voltage (100%) selected with the AVR voltage select function (A082).

If the motor operation is cranky, try to decrease the gain setting.

Item

Function code

Range of data

Description

V/f gain setting

A045/A245

20. to 100. (%)

Setting of the rate of reducing the output voltage

AVR voltage

select (100%)

Base

frequency

Maximum

frequency

A045/A245

A082/A282 (100%)

A082/A282 * A045/A245 (%)

Summary of Contents for NES1-002LB

Page 9: ......

Page 21: ......

Page 25: ......

Page 28: ...Chapter 3 Exterior Views 3 3 ...

Page 30: ......

Page 35: ......

Page 53: ......

Page 75: ......

Page 154: ......

Page 196: ......

Page 203: ...Chapter 10 Troubleshooting This chapter describes the troubleshooting methods ...

Page 204: ......

Page 211: ......

Page 219: ......

Page 229: ......

Page 289: ...Appendix Appendix A Appendix A 1 ...

Page 290: ......

Page 292: ...Appendix Appendix 2 ...