Multiple-Axis Machining | Miscellaneous functions for rotary axes

13

620

HEIDENHAIN | TNC 640 | Conversational Programming User's Manual | 10/2017

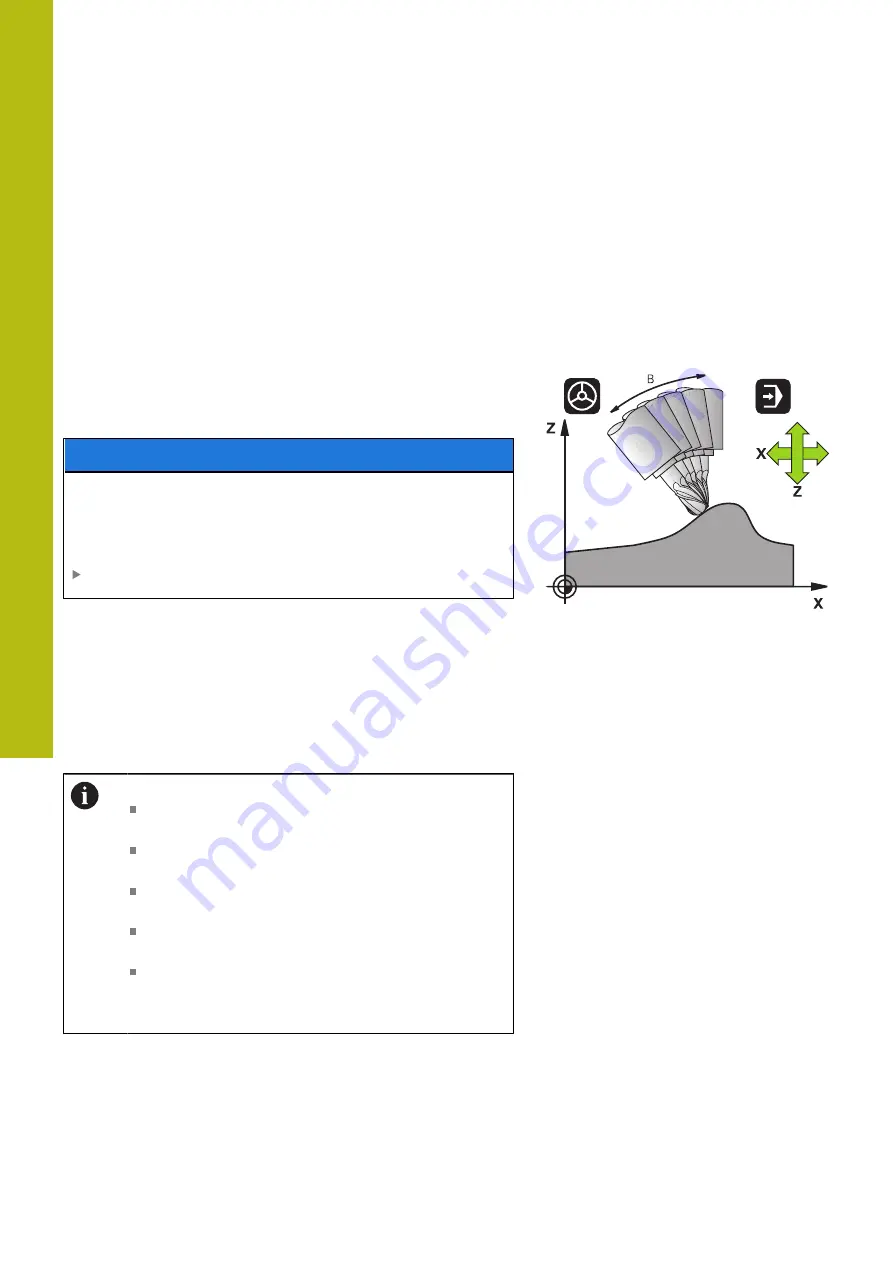

Maintaining the position of the tool tip when

positioning with tilted axes (TCPM): M128 (option 9)

Standard behavior

If the inclination angle of the tool changes this results in an offset

of the tool tip compared to the nominal position. The control does

not compensate this offset. If the operator does not take this

deviation into account in the NC program, offset machining is

executed.

Behavior with M128 (TCPM: Tool Center Point Management)

If the position of a controlled tilted axis changes in the program,

the position of the tool tip in relation to the workpiece remains the

same during the tilting process.

NOTICE

Danger of collision!

Rotary axes with Hirth coupling must move out of the coupling

to enable tilting. There is a danger of collision while the axis

moves out of the coupling and during the tilting operation.

Tool retracted before the position of the tilting axis is changed

After

M128

, you can program a feed rate at which the control will

carry out the compensation movements in the linear axes.

If you want to change the position of the tilting axis with the

handwheel during the program run, use

M128

along with

M118

.

Superimposing handwheel positioning is implemented with active

M128

, depending on the setting in the 3D-ROT menu of the

Manual

operation

operating mode, in the active coordinate system or in

the non-tilted coordinate system.

Programming notes:

Before positioning axes with

M91

or

M92

and before

a

TOOL CALL

block, reset the

M128

function

To avoid contour damage, you must use only

spherical cutters with

M128

.

The tool length must refer to the spherical center of

the tool tip.

If

M128

is active, the control shows the

TCPM

symbol in the status display

The

TCPM

or

M128

function cannot be used in

conjunction with the

Dynamic Collision Monitoring

(DCM)

function and the additional

M118

function

Summary of Contents for TNC 640

Page 4: ......

Page 5: ...Fundamentals ...

Page 36: ...Contents 36 HEIDENHAIN TNC 640 Conversational Programming User s Manual 10 2017 ...

Page 67: ...1 First Steps with the TNC 640 ...

Page 90: ......

Page 91: ...2 Introduction ...

Page 130: ......

Page 131: ...3 Operating the Touchscreen ...

Page 144: ......

Page 145: ...4 Fundamentals File Management ...

Page 206: ......

Page 207: ...5 Programming Aids ...

Page 236: ......

Page 237: ...6 Tools ...

Page 281: ...7 Programming Contours ...

Page 333: ...8 Data Transfer from CAD Files ...

Page 355: ...9 Subprograms and Program Section Repeats ...

Page 374: ......

Page 375: ...10 Programming Q Parameters ...

Page 478: ......

Page 479: ...11 Miscellaneous Functions ...

Page 501: ...12 Special Functions ...

Page 584: ......

Page 585: ...13 Multiple Axis Machining ...

Page 650: ......

Page 651: ...14 Pallet Management ...

Page 664: ......

Page 665: ...15 Batch Process Manager ...

Page 673: ...16 Turning ...

Page 713: ...17 Manual Operation and Setup ...

Page 797: ...18 Positioning with Manual Data Input ...

Page 803: ...19 Test Run and Program Run ...

Page 843: ...20 MOD Functions ...

Page 881: ...21 Tables and Overviews ...