Multiple-Axis Machining | The PLANE function: Tilting the working plane (option 8)

13

HEIDENHAIN | TNC 640 | Conversational Programming User's Manual | 10/2017

607

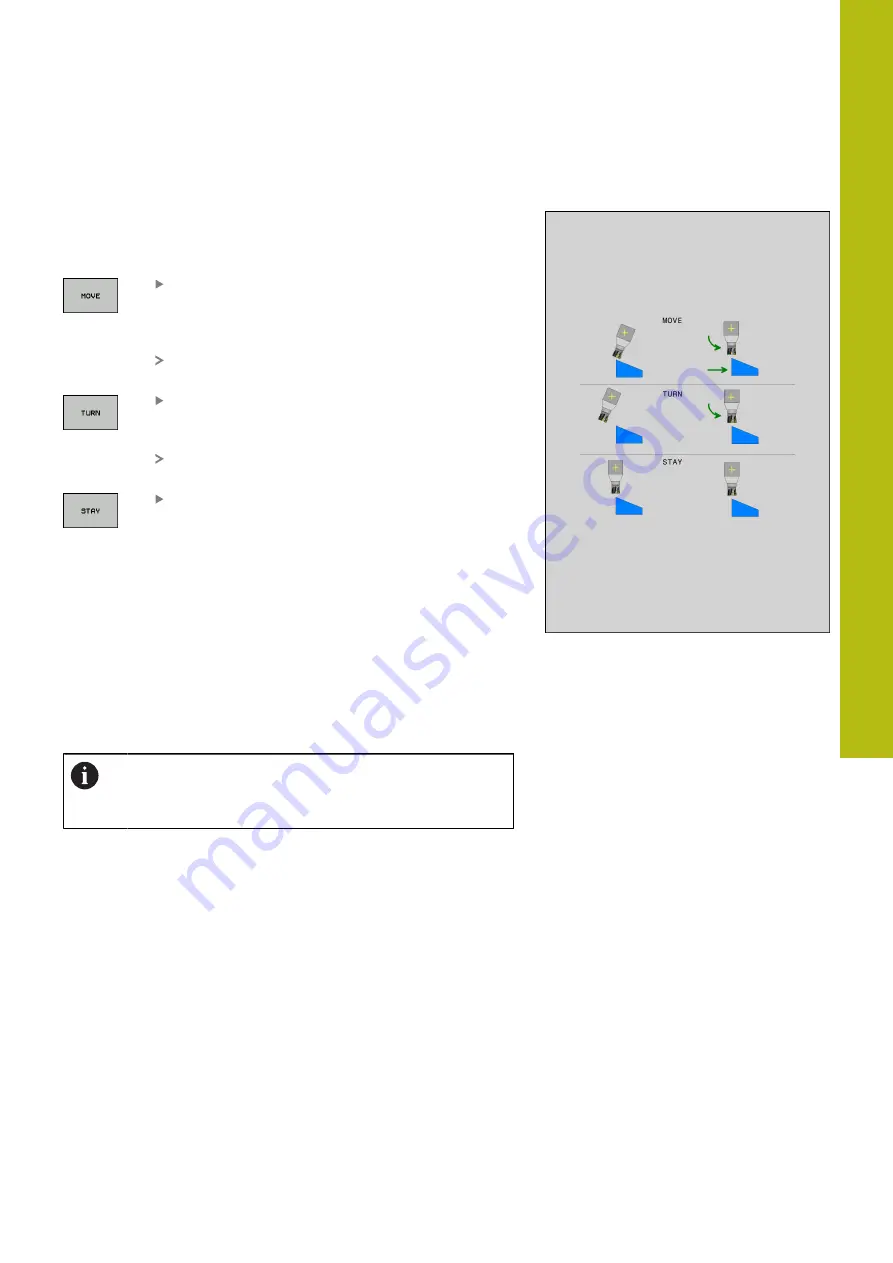

Automatic positioning: MOVE/TURN/STAY (entry is

mandatory)

After you have entered all parameters for the plane definition,

you must specify how the rotary axes will be positioned to the

calculated axis values:

The PLANE function is to automatically position

the rotary axes to the calculated position values.

The position of the tool relative to the workpiece

remains the same.

The control carries out a compensation

movement in the linear axes.

The PLANE function is to automatically position

the rotary axes to the calculated position values,

but only the rotary axes are positioned.

The control does

not

carry out a compensation

movement for the linear axes.

You will position the rotary axes later in a

separate positioning block

If you selected the

MOVE

option (the

PLANE

function is used to

position the axes automatically), the following two parameters:

Dist. tool tip – center of rot.

and

Feed rate? F =

are still to be

defined.

If you selected the

TURN

option (the

PLANE

function is used to

position the axes automatically), the following parameter:

Feed

rate? F =

is still to be defined.

As an alternative to defining a feed rate

F

directly by entering a

numerical value, you can also position the axes with

FMAX

(rapid

traverse) or

FAUTO

(feed rate from the

TOOL CALL

block).

If you use

PLANE

together with

STAY,

you have to

position the rotary axes in a separate block after the

PLANE

function.

Summary of Contents for TNC 640

Page 4: ......

Page 5: ...Fundamentals ...

Page 36: ...Contents 36 HEIDENHAIN TNC 640 Conversational Programming User s Manual 10 2017 ...

Page 67: ...1 First Steps with the TNC 640 ...

Page 90: ......

Page 91: ...2 Introduction ...

Page 130: ......

Page 131: ...3 Operating the Touchscreen ...

Page 144: ......

Page 145: ...4 Fundamentals File Management ...

Page 206: ......

Page 207: ...5 Programming Aids ...

Page 236: ......

Page 237: ...6 Tools ...

Page 281: ...7 Programming Contours ...

Page 333: ...8 Data Transfer from CAD Files ...

Page 355: ...9 Subprograms and Program Section Repeats ...

Page 374: ......

Page 375: ...10 Programming Q Parameters ...

Page 478: ......

Page 479: ...11 Miscellaneous Functions ...

Page 501: ...12 Special Functions ...

Page 584: ......

Page 585: ...13 Multiple Axis Machining ...

Page 650: ......

Page 651: ...14 Pallet Management ...

Page 664: ......

Page 665: ...15 Batch Process Manager ...

Page 673: ...16 Turning ...

Page 713: ...17 Manual Operation and Setup ...

Page 797: ...18 Positioning with Manual Data Input ...

Page 803: ...19 Test Run and Program Run ...

Page 843: ...20 MOD Functions ...

Page 881: ...21 Tables and Overviews ...