Network Configuration

59

•

•

•

•

•

•

Printer (over RS-232)

The HI 6500 series can transmit Gross, Net, Count, Tare values to a serial printer over RS-

232. The printer Baud rate is user selectable at 600, 1200, 2400, 4800, 9600, or 19200

(default is 9600).

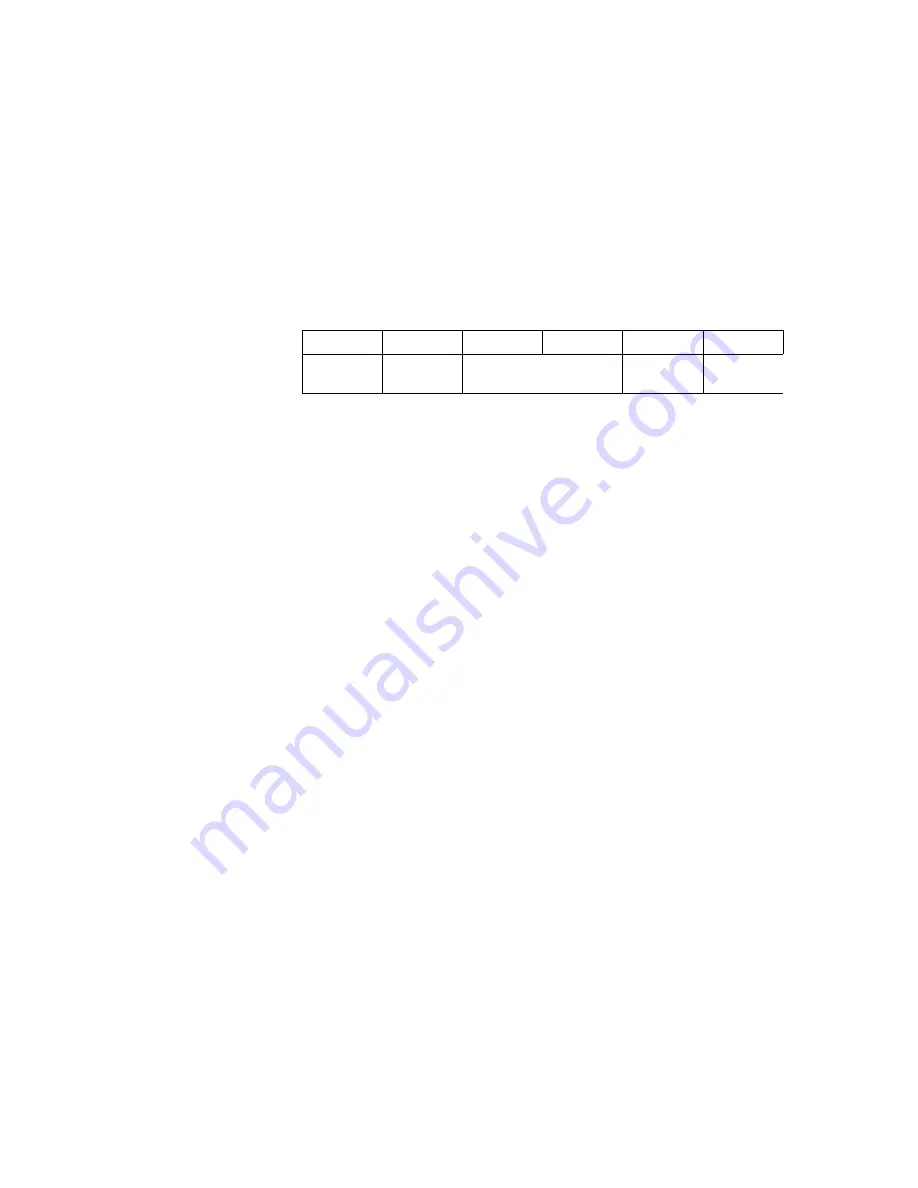

The RS-232 printer pinout is:

A sample wiring connection from the HI 6500 series

to the printer port is shown above.

The printer parameters can be configured through the web interface or the display panel.

Step 1.

Set the baud rate for the RS232 printer, default is 9600.

Step 2.

Set the parity bit, default is EVEN

Step 3.

Select what values to transmit over the serial interface to the printer using the

printer mode, default is disabled.

a. Gross Weight

b. Net Weight

c. Tare Weight

d. Unit Count

e. All – Gross, Net, Tare, and Count (if Count enabled) values

f. OFF, Printer disabled.

USB Memory Stick

The HI 6500 series provides an interface to an external USB memory stick that allows

HI 6500 parameters to be saved, restored. or copied to another instrument.

NOTE

The HI 6500 series does not include a USB memory stick port when used in a Swivel Mount

Enclosure. See Appendix A for further information.

The USB memory stick commands can be activated through the web interface or the

display panel.

To access the USB Menu, from the front keypad, select Configuration > Enter,

Communications > Enter, USB >Enter, UP or DOWN arrow to Save or Restore > Enter.

On the

Web page

: Configuration; communications; USB; save/restore.

GND

DNC

TR+

TR-

PrtRX

PrtTX

Signal

Ground

DO Not

Connect

RS485 Pins Not Used Printer RX Printer TX

Summary of Contents for HI 6500 Series

Page 10: ...viii Contents ...

Page 20: ...10 Chapter 2 ...

Page 72: ...62 Chapter 4 ...

Page 96: ...86 Chapter 5 Profibus DP Commands and Parameters ...

Page 97: ...Instrument Configuration 87 Serial Option Termination ...

Page 126: ...116 Chapter 5 ...

Page 156: ...146 Chapter 8 ...

Page 163: ...Troubleshooting 153 General Troubleshooting Flow Chart Index ...

Page 164: ...154 Chapter 9 A Guideline Instability Electrical and Mechanical review ...

Page 165: ...Troubleshooting 155 A1 Checking for Unstable Components in a Weighing System ...

Page 166: ...156 Chapter 9 B Guidelines for Electrical Mechanical or Configuration Issues ...

Page 167: ...Troubleshooting 157 B1 Guidelines to Verify Electrical Installation ...

Page 168: ...158 Chapter 9 B2 Guidelines to Verify Mechanical Installation ...

Page 170: ...160 Chapter 9 C Integrated Technician and Stability Test Overview ...

Page 171: ...Troubleshooting 161 E Testing for Non Return to Zero System with IT Summing Card ...

Page 173: ...Troubleshooting 163 G Calibration Errors When Performing the Calibration ...

Page 174: ...164 Chapter 9 H Mechanical Installation ...

Page 175: ...Troubleshooting 165 J Electrical Inspection ...

Page 176: ...166 Chapter 9 K Installation Check Points ...

Page 177: ...Troubleshooting 167 M Weight Processor s Front Display is Blank or Locked ...

Page 178: ...168 Chapter 9 N Analog Out HI 6510 Only ...

Page 194: ...184 Appendix A Figure D1 Assembling the Swivel Mount Enclosure on the instrument pedestal ...

Page 196: ...186 Appendix A Dimensions ...

Page 200: ...4 HI 6500 Series USER GUIDE Index ...

Page 201: ......