Network Configuration

41

•

•

•

•

•

•

If you do not have a Modbus PLC available to test the Modbus communications, then you

can download the Hardy Modbus Link test software from the Hardy Web site at

http://www.hardysolutions.com. This program can be found currently on the HI 4050

products page under the Docs & Programs tab.

Installing the Hardy Modbus-Link Test Package:

If you do not have a PLC or other

client, Hardy has provided the Hardy Modbus-Link Client to test communications with the

HI 6500 unit. This client package only communicates with the unit and is not a full

communications package. If you have problems with this test, contact Hardy Technical

Support. Double click the Hardy Modbus-Link .exe file to install the software on your PC.

Upon completion, a Hardy Modbus-Link icon appears on your Desktop.

Modbus services are specified by function codes that are elements of MODBUS request /

reply PDUs. MODBUS is implemented for the HI 6500 using TCP/IP over Ethernet. The

Client/Server definitions are as follows:

•

Client - The module asking for data.

•

Server - The module providing the data.

NOTE

MODBUS is positioned at level 7 of the OSI model and is accessed at a reserved system

port 502 on the TCP/IP stack. It will support communication with up to 10 different hosts

(sockets).

Configuring MODBUS

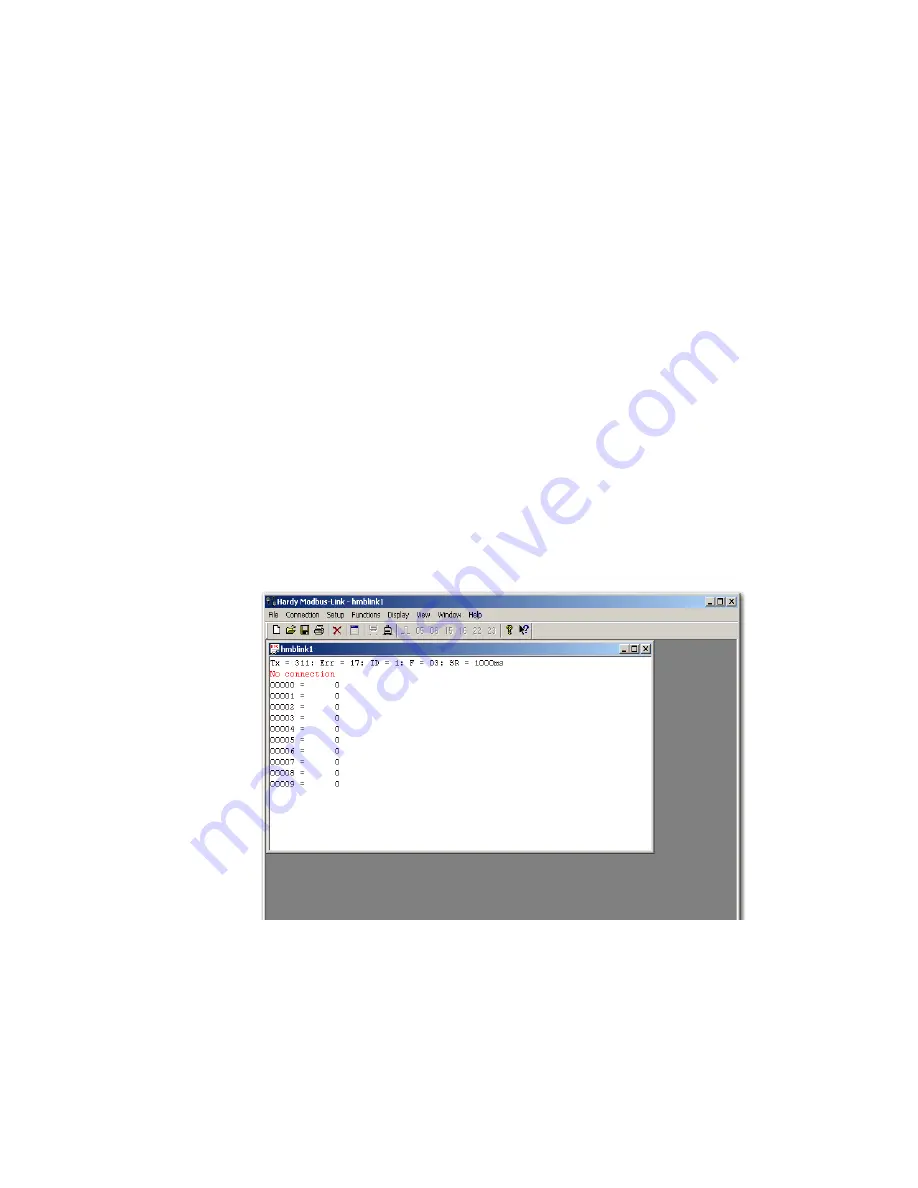

Step 1. Click the Hardy Modbus-Link icon to open the Hardy Modbus-Link display.

Summary of Contents for HI 6500 Series

Page 10: ...viii Contents ...

Page 20: ...10 Chapter 2 ...

Page 72: ...62 Chapter 4 ...

Page 96: ...86 Chapter 5 Profibus DP Commands and Parameters ...

Page 97: ...Instrument Configuration 87 Serial Option Termination ...

Page 126: ...116 Chapter 5 ...

Page 156: ...146 Chapter 8 ...

Page 163: ...Troubleshooting 153 General Troubleshooting Flow Chart Index ...

Page 164: ...154 Chapter 9 A Guideline Instability Electrical and Mechanical review ...

Page 165: ...Troubleshooting 155 A1 Checking for Unstable Components in a Weighing System ...

Page 166: ...156 Chapter 9 B Guidelines for Electrical Mechanical or Configuration Issues ...

Page 167: ...Troubleshooting 157 B1 Guidelines to Verify Electrical Installation ...

Page 168: ...158 Chapter 9 B2 Guidelines to Verify Mechanical Installation ...

Page 170: ...160 Chapter 9 C Integrated Technician and Stability Test Overview ...

Page 171: ...Troubleshooting 161 E Testing for Non Return to Zero System with IT Summing Card ...

Page 173: ...Troubleshooting 163 G Calibration Errors When Performing the Calibration ...

Page 174: ...164 Chapter 9 H Mechanical Installation ...

Page 175: ...Troubleshooting 165 J Electrical Inspection ...

Page 176: ...166 Chapter 9 K Installation Check Points ...

Page 177: ...Troubleshooting 167 M Weight Processor s Front Display is Blank or Locked ...

Page 178: ...168 Chapter 9 N Analog Out HI 6510 Only ...

Page 194: ...184 Appendix A Figure D1 Assembling the Swivel Mount Enclosure on the instrument pedestal ...

Page 196: ...186 Appendix A Dimensions ...

Page 200: ...4 HI 6500 Series USER GUIDE Index ...

Page 201: ......