52

Chapter

4

•

•

•

•

•

•

allocation list, and the bus parameters for all connected stations. A master uses this

information to set up communication with each slave during startup. Slaves can only

acknowledge the messages they receive or transfer messages to a master when the latter

requests a slave to do so. Slaves are also designated as passive nodes.

Refer to the section, “

I/O Tables For Communications to PLCs,”

earlier in this chapter for

an understanding of the data and format for the Profibus communications.

For a full list of command parameters, please see the "

Default Parameter IDs and Values

"

at the end of Chapter 5.

NOTE

Profibus-DP provides a very flexible network solution. In addition to the basic guideline

provided in this manual, your installation could require procedures that are beyond the

scope of this manual. For more information and to locate lists of links to other sources of

Profibus-DP information, check the Profibus website at

.

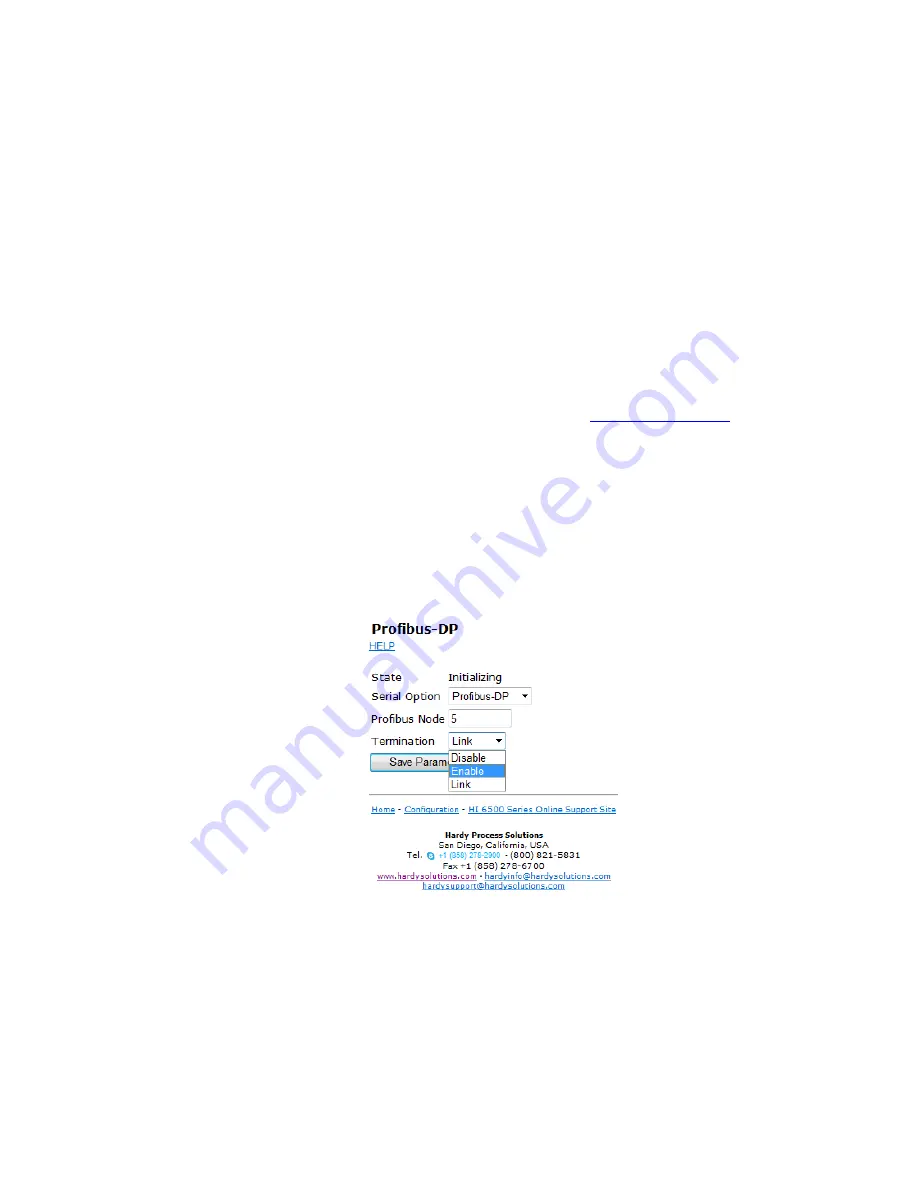

Configuring PROFIBUS From the Web Interface

Step 1. Step 1. From the Configuration menu select Options to open the Options menu;

then Click on Profibus Card. to open then Click on Profibus Card form. Double

click in the Node text field to highlight the current entry. Type in the HI 6500 OR

HI 6510 Node address. Range:1-125 (default 5) Our example uses the default

address #5.

NOTE

Profibus Node Address #5 is the lowest number that can be used by a slave device.

Summary of Contents for HI 6500 Series

Page 10: ...viii Contents ...

Page 20: ...10 Chapter 2 ...

Page 72: ...62 Chapter 4 ...

Page 96: ...86 Chapter 5 Profibus DP Commands and Parameters ...

Page 97: ...Instrument Configuration 87 Serial Option Termination ...

Page 126: ...116 Chapter 5 ...

Page 156: ...146 Chapter 8 ...

Page 163: ...Troubleshooting 153 General Troubleshooting Flow Chart Index ...

Page 164: ...154 Chapter 9 A Guideline Instability Electrical and Mechanical review ...

Page 165: ...Troubleshooting 155 A1 Checking for Unstable Components in a Weighing System ...

Page 166: ...156 Chapter 9 B Guidelines for Electrical Mechanical or Configuration Issues ...

Page 167: ...Troubleshooting 157 B1 Guidelines to Verify Electrical Installation ...

Page 168: ...158 Chapter 9 B2 Guidelines to Verify Mechanical Installation ...

Page 170: ...160 Chapter 9 C Integrated Technician and Stability Test Overview ...

Page 171: ...Troubleshooting 161 E Testing for Non Return to Zero System with IT Summing Card ...

Page 173: ...Troubleshooting 163 G Calibration Errors When Performing the Calibration ...

Page 174: ...164 Chapter 9 H Mechanical Installation ...

Page 175: ...Troubleshooting 165 J Electrical Inspection ...

Page 176: ...166 Chapter 9 K Installation Check Points ...

Page 177: ...Troubleshooting 167 M Weight Processor s Front Display is Blank or Locked ...

Page 178: ...168 Chapter 9 N Analog Out HI 6510 Only ...

Page 194: ...184 Appendix A Figure D1 Assembling the Swivel Mount Enclosure on the instrument pedestal ...

Page 196: ...186 Appendix A Dimensions ...

Page 200: ...4 HI 6500 Series USER GUIDE Index ...

Page 201: ......