8 – 2

Section 8

•

Timers

Vission 20/20 • Operation and Service Manual • Emerson • 35391SC 2.7

(Run) Oil Pressure setpoints will be adjusted by the

values of the Pre-lube Oil Pressure setpoints. After

the timer has expired, the normal Low Oil Pressure

setpoints become active.

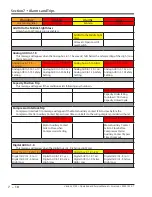

Prelube Oil Pressure Monitor Time:

•

The Prelube Oil Pressure Monitor time defines timer

to monitor raise in prelube oil pressure against pre-

lube oil pressure alarm settings. If prelube oil pres-

sure is unable to raise by oil pressure alarm settings

in Prelube oil pressure monitor time then it restarts

oil pump.

Prelube Oil Pressure Monitor Trials:

•

The Prelube oil pressure monitor trials defines

maximum number of retries to monitor prelube oil

pressure.

Prelube Oil Pressure Safety Changeover:

• After compressor starts, the drop in prelube oil pres-

sure is monitored for prelube oil pressure safety

changeover time. If prelube oil pressure drops with

in prelube oil pressure safety changeover time then

compressor trips on prelube oil pressure trip.

High Filter Differential Pressure Safety Changeover:

• This timer bypasses the High Filter Differential Run

Pressure safety settings when the compressor starts.

It defines how long the High Filter Differential Start

Pressure setpoints will be active after the compres-

sor starts. After the timer has expired, then the High

Filter Differential Run Pressure safety setpoints will be

active.

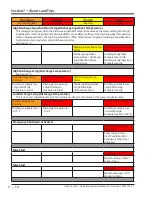

Oil Separator Level #1 Safety Trip Delay:

• This timer bypasses the low oil level switch for mo-

mentary drops in the oil level. This timer activates

when the low oil level switch opens, and deactivates

when the switch closes. If the switch is still open af-

ter the timer has timed out, the compressor will be

shut down and a trip message will be displayed. This

timer is available if the unit is equipped with a low oil

separator float switch (the oil level switch is standard

on all liquid injection units and optional on all others).

Oil Separator Level #2 Safety Trip Delay:

• This timer bypasses the low oil level switch for mo-

mentary drops in the oil level. This timer activates

when the low oil level switch opens, and deactivates

when the switch closes. If the switch is still open af-

ter the timer has timed out, the compressor will be

shut down and a trip message will be displayed. This

timer is available if the unit is equipped with a low oil

separator float switch (the oil level switch is standard

on all liquid injection units and optional on all others).

Low Oil Separator Temperature Safety Changeover:

• This timer allows Low Oil Separator Start Temperature

safety setpoint to protect the compressor against

cold oil during starting. After the timer has expired,

the Low Oil Separator Run Temperature is then active.

Low Oil Injection Temperature Safety Bypass:

• This timer bypasses the Low Oil Injection Temperature

Safety setpoint during start-up, to allow any cold oil in

the oil lines and filter to pass. After the timer expires,

the Low Oil Injection Temperature safety is active.

Communication Failure Detect Timer:

• This timer forces the compressor to wait for the set

time period before displaying “Remote Comm Time-

out” Alarm in yellow banner or “Remote Comm

Time-out” Trip in red banner when there is no remote

communication to Vission 20/20 for configured time.

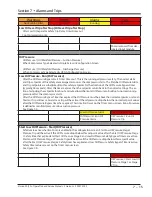

Max Restart After Power Failure:

• This timer forces the compressor to wait for the set

time period after a power failure and for the panel’s

restart before it can be started automatically. By

staggering the time settings of this timer between

other compressor panels, the compressors can be

allowed to start automatically, one at a time, after

a power failure. This will prevent excessive load de-

mand on the power system that could occur if all of

the compressor equipment were to start at the same

time. The Power-up Auto Re-Start [x]Enable option

must be selected on the Configuration screen for this

option to be active.

Hot Starts per Hour:

• This counter counts compressor starts. After every

start, a one-hour timer is reset and starts timing. If

the timer times out, the hot starts counter is reset.

When the counter reaches its preset value, it will not

allow another compressor start until the one-hour

timer times out and resets the counter. The hot starts

counter, therefore, will be reset when the time be-

tween compressor starts total one hour. This coun-

ter allows repetitive compressor starts, but once the

counter has reached its set point, it requires a one-

hour window between compressor starts in order for

the counter to be reset.

True Anti-Recycle Timer:

• Once the compressor turns off, this timer will keep

the compressor off for the setting of the True Anti-

Recycle Timer. This timer is used to prevent short cy-

cling of the compressor.

Summary of Contents for Vilter Vission 20/20

Page 1: ...Vission 20 20TM Micro controller Operation and service manual Version 2 7 ...

Page 2: ......

Page 4: ......

Page 220: ...B 2 Blank Vission 20 20 Operation and Service Manual Emerson 35391SC 2 7 ...

Page 300: ...D 2 Blank Vission 20 20 Operation and Service Manual Emerson 35391SC 2 6 ...

Page 336: ......

Page 337: ......