85

b

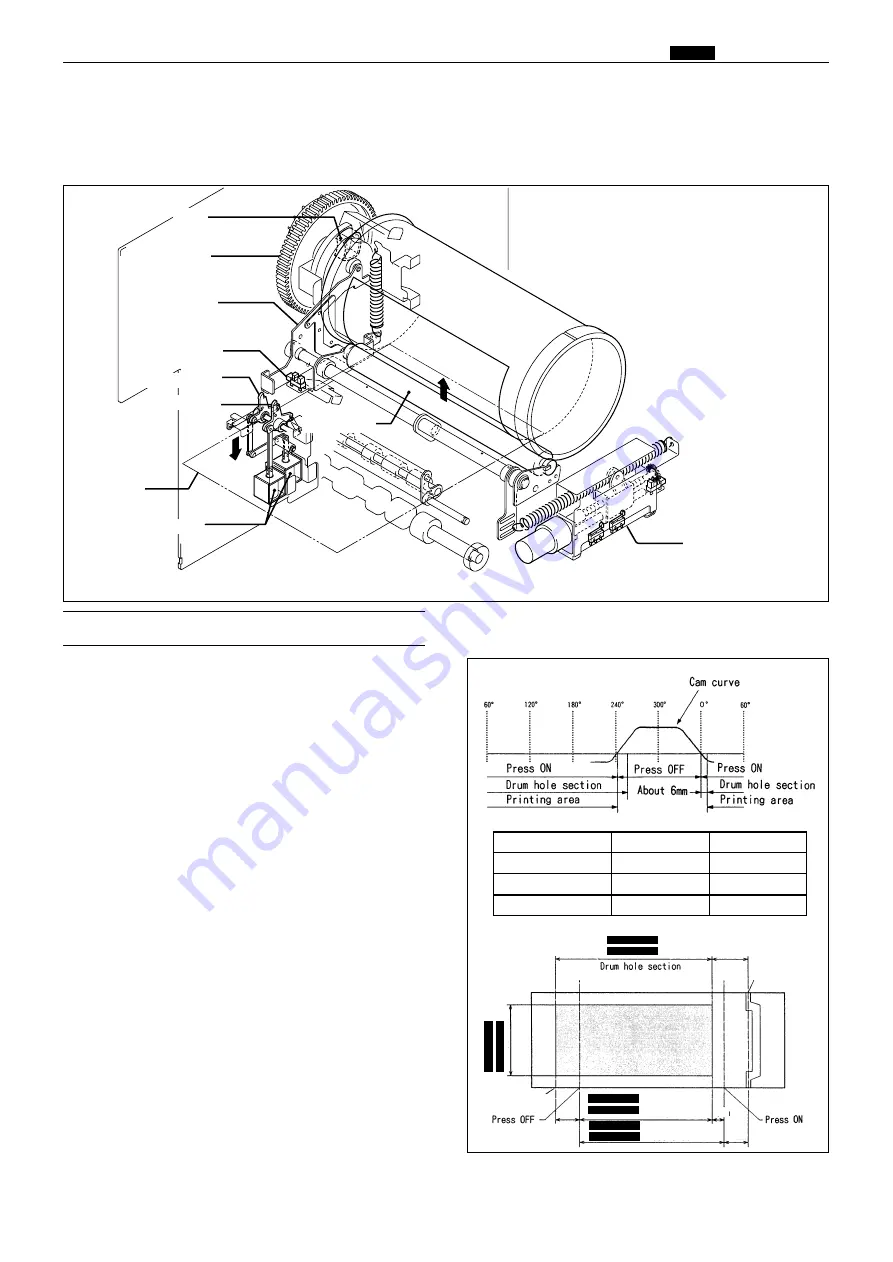

Press Section

chap.2

b

Press Section

1. Description

(1) Press Roller Timing & Printing Area

Description

In this machine, the master is rolled up to the

drum, ink is transferred to the drum and the

printing paper is pressed to the drum by the press

roller to print.

Printing is performed on only the sections that

meet the following requirements.

1) The sections of the master on which holes are

made by processing platemaking. (platemaking area)

2) The hole sections of the drum.

3) The section of the drum pressed with the

press roller. (the area pressed ON)

When the pressed-on position is 0 under the

normally adjusted conditions, relations among 1), 2)

and 3) are as follows*-

Drum gear

Press roller

Press lever

P-roll sensor

(mm)

DP-460/440/430

428

438

423

Press ON length

Drum hole section length

Printing area length

440308

Center of the

master clamp shaft

Bottom end of the

hole section

Cam

Paper

Cancel lever

Signal solenoid

Contact pressure unit

70

423

15

6

54

( mm )

Cancel lever

DP-340/330330L

370

370

355

: 438

: 370

DP-340/330/330L

DP-460/440/430

: 423

: 355 Printing area

DP-340/330/330L

DP-460/440/430

: 310

: 270

DP-340/330/330L

DP-460/440/430

: 428

: 370 Press area

DP-340/330/330L

DP-460/440/430

Summary of Contents for Duprinter DP-330

Page 9: ......

Page 11: ......

Page 18: ...c Dimensions chap 1 17 MEMO...

Page 24: ...4 8 2A 2B 2C 44000A1e b Part Names and Their Functions chap 1 23...

Page 152: ...151 MEMO...

Page 193: ...192 MEMO...

Page 329: ...328 x Overall Wiring Layout chap 8 15 Overall Wiring Layout 2 Drive PCB 2 2...