167

c

Paper Feed Section

chap.4

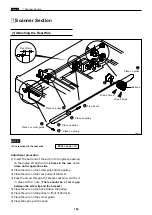

(6) Adjusting the G Roll Escape Amount /

Timing

Adjustment procedure

1) Pull out the drum while the drum is in the stop

position.

2) Loosen the eccentric shaft fixing screw and

adjust so that the clearance between the timing

roller and the guide roller becomes

0.5 mm

.

¡

For description of operation.

\

See page 70

NOTE :

Standard value

Item

Clearance between timing roller

and guide roller

0.5 mm

440121

0.5mm

Eccentric

shaft

Screw

Timing roller

Guide roller

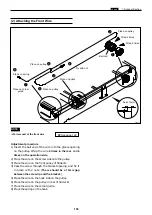

(5) Adjusting the Double Feed Detection Sensor

¡

For description of operation.

¡

For removal.

Adjustment method

1) Access HELP mode H-06.

For the accessing HELP modes:

2) Photointerrupt the double feed detection sensor

by one piece of wood free paper (55kg).

3) Adjust the sensor with

VR1

on the drive PCB so

that the value is set to

“105”

.

4) Photointerrupt the double feed detection sensor

by two pieces of wood free paper (55kg).

5) Check that the value is

“57”

.

\

See page 219

HELP mode H-06

\

see p.232

\

See page 135

\

See page 74

NOTE :

440163

VR1

¡

Drive PCB

Standard value

Summary of Contents for Duprinter DP-330

Page 9: ......

Page 11: ......

Page 18: ...c Dimensions chap 1 17 MEMO...

Page 24: ...4 8 2A 2B 2C 44000A1e b Part Names and Their Functions chap 1 23...

Page 152: ...151 MEMO...

Page 193: ...192 MEMO...

Page 329: ...328 x Overall Wiring Layout chap 8 15 Overall Wiring Layout 2 Drive PCB 2 2...