Diagnostic information

2-141

Sensor (pass through) static jam service check

4

Check the above sensor for proper connection.

Is the above sensor connected properly?

Replace the

appropriate

Sensor (pass

through).

Go to

“250-sheet

controller card

assembly

removal” on

page 4-107

.

Replace the

connection.

5

Perform a print test and check the main motor assembly.

Is the media properly transported through the pass through

areas of the media trays?

Replace the main

drive motor

assembly.

Go to

“Output

cover assembly

removal” on

page 4-54

.

Replace the

connection.

6

Perform a print test using the appropriate input tray.

Does the error continue?

Replace the input

option.

Problem solved.

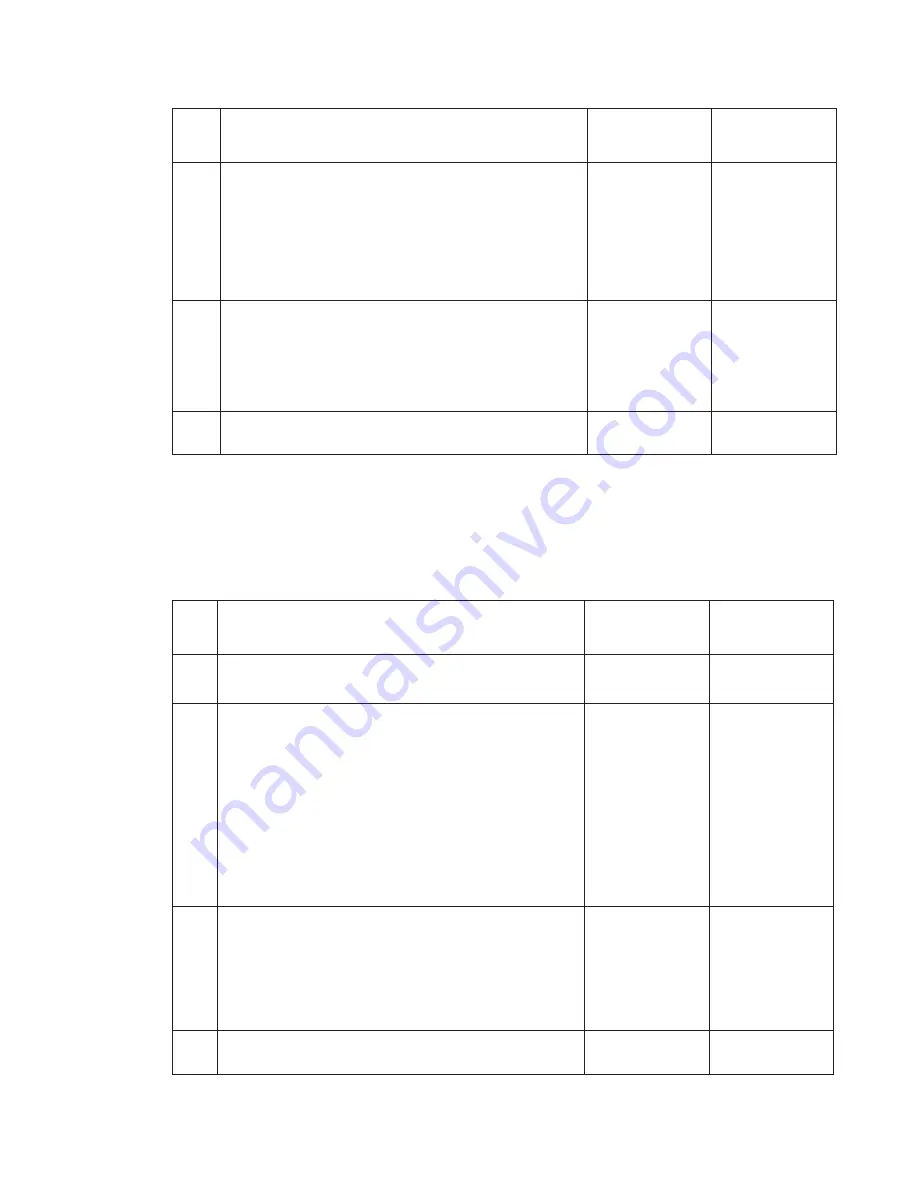

Use this procedure for the following jams:

• 242.13

• 242.36

• 243.13

• 243.36

244.13

• 244.36

• 245.13

• 245.36

Step

Check

Yes

No

1

Check the media path for partially fed or jammed media.

Is the media path free from partially fed or jammed media?

Go to step 2.

Remove any pre-

staged or jammed

media.

2

Check the appropriate media tray sensor (pass through) for

proper operation.

1. Enter the diagnostic mode

2. Select Input tray tests

3. Sensor test

4. Select the appropriate tray number

3. Observe the line item “pass through” for the appropriate

media tray

Does the display on the operator panel, change every time

the sensing area of the above sensor is interrupted or

blocked.

Go to step 5.

Go to step 4.

3

Check the above sensor for proper connection.

Is the above sensor connected properly?

Replace the

appropriate sensor

(pass through).

Go to

“250-sheet

controller card

assembly

removal” on

page 4-107

.

Replace the

connection.

4

Perform a print test using the appropriate input tray.

Does the error continue?

Replace the input

option.

Problem solved.

Step

Check

Yes

No

Summary of Contents for 5230DN

Page 1: ... HOO Q GQ GQ GQ 6HUYLFH 0DQXDO 15 December 2009 ...

Page 2: ... ...

Page 14: ...xiv Service Manual ...

Page 19: ...Notices and safety information xix ...

Page 20: ...xx Service Manual ...

Page 34: ...1 10 Service Manual ...

Page 206: ...2 172 Service Manual ...

Page 318: ...3 112 Service Manual ...

Page 366: ...4 48 Service Manual 6 Remove the operator panel hinge assembly right ...

Page 369: ...Repair Information 4 51 9 Lift the operator panel door assembly out of the machine ...

Page 436: ...4 118 Service Manual 3 Remove the HCIT tray cover front A ...

Page 438: ...4 120 Service Manual 3 Remove the HCIT cover rear ...

Page 440: ...4 122 Service Manual 3 Remove the HCIT cover right ...

Page 469: ...Repair Information 4 151 5 Install the flash card into the system board ...

Page 518: ...4 200 Service Manual ...

Page 520: ...5 2 Service Manual ...

Page 524: ...7 2 Service Manual Assembly 1 Covers ...

Page 526: ...7 4 Service Manual Assembly 2 5230n dn 5350dn and 5530dn Operator panel ...

Page 528: ...7 6 Service Manual Assembly 3 T656dne Operator panel MPF and smart card ...

Page 530: ...7 8 Service Manual Assembly 4 Drive motor assemblies and duplex ...

Page 532: ...7 10 Service Manual Assembly 5 Media path and ducts 1 2 2 3 4 5 6 7 8 9 10 11 12 12 ...

Page 534: ...7 12 Service Manual Assembly 6 Printhead charge and transfer ...

Page 536: ...7 14 Service Manual Assembly 7 Pick arm assembly trays and MPF ...

Page 538: ...7 16 Service Manual Assembly 8 LVPS fuser and electrical cables 1 ...

Page 540: ...7 18 Service Manual Assembly 9 HVPS system card and electrical cables 2 ...

Page 548: ...7 26 Service Manual Assembly 13 SFP stapler assembly 1 1 ...

Page 552: ...7 30 Service Manual Assembly 15 SFP stapler assembly 3 4 5 1 2 3 6 6 7 8 9 10 11 ...

Page 554: ...7 32 Service Manual Assembly 16 SFP stapler assembly 4 1 2 ...

Page 556: ...7 34 Service Manual Assembly 17 5 bin mailbox 1 3 12 7 5 2 11 4 13 8 10 9 1 14 6 ...

Page 564: ...7 42 Service Manual Assembly 21 Envelope feeder and external duplex 1 2 ...

Page 582: ...I 12 Service Manual ...

Page 584: ...5230n dn Printer ...

Page 585: ...5 5 30dn Printer ...

Page 586: ...5 35 0dn Printer ...