4/Tests and Troubleshooting

1503-0151-000

5/26/0

4-39

IMPORTANT If the ventilator experiences extreme electrical interference, it may

interrupt mechanical ventilation. If this interruption occurs, the ven-

tilator generates an internal reset function and resumes normal op-

eration after two (2) seconds. For situations where continuous

electrical interference is experienced by the ventilator, causing a

continuous interruption, the ventilator's internal reset repeats until

the interference ceases.

If the electrical interference is continuously present and mechanical

ventilation is interrupted for approximately 30 seconds, the ventila-

tor produces a continuous beeping audio alarm. Manual ventilation

of the patient must be performed while the mechanical ventilation is

interrupted. When the electrical interference ceases, the continuous

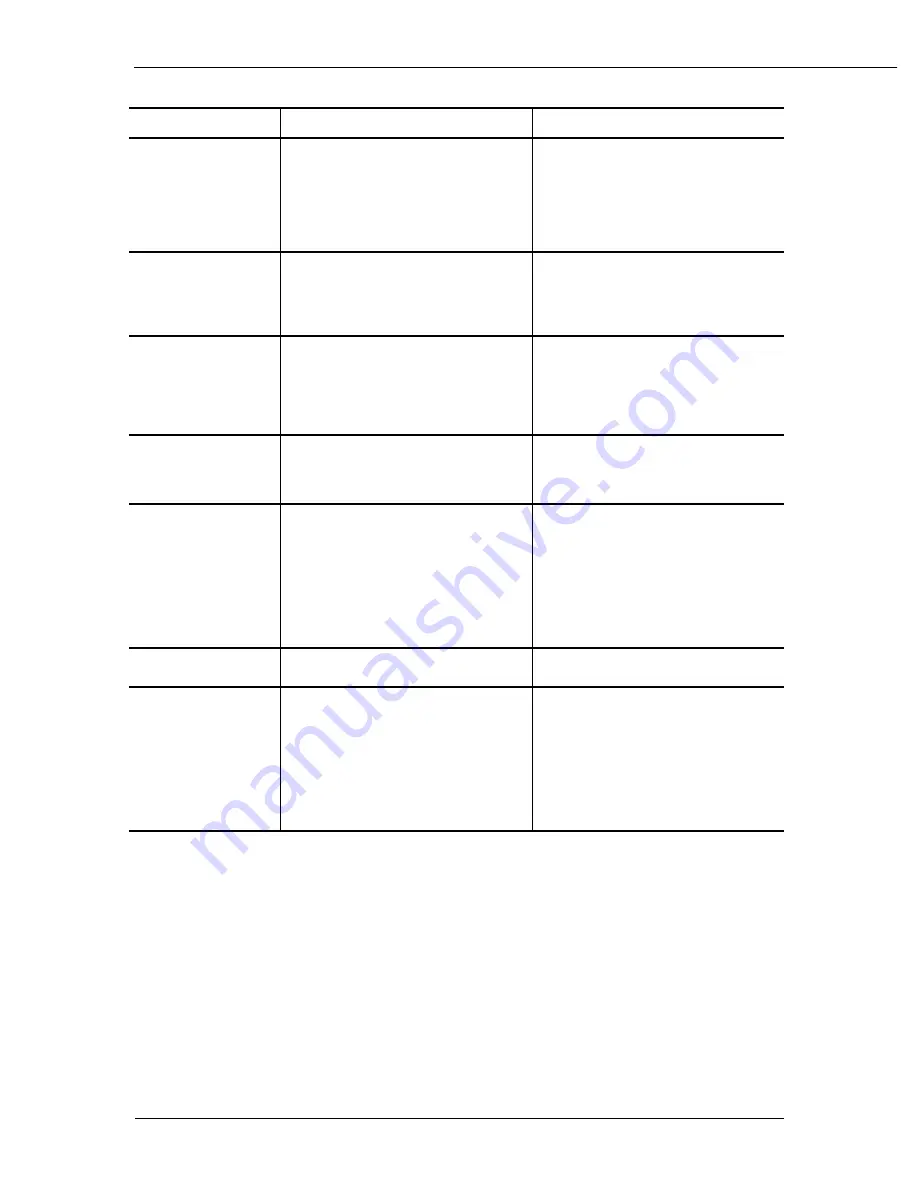

Symptom

Probable Cause

Action

Bellows distended

and/or slips off base.

1. Bellows retention problem.

2. Bellows assembly exhaust

restricted.

3. Bellows assembly pressure relief

valve problem.

1. Check bellows.

2. Check the waste gas scavenging

system for high vacuum or blockage.

3. Control port plugged or drive gas

inlet hose blocked.

Continuous flow of

supply gas before

machine is turned

ON.

1. External hose leak.

2. GIV leak.

1. Check hose.

2. Check GIV solenoid.

3. Repair GIV

Bellows does not

descend during inspi-

ration.

1. Bag/APL-Vent selector in Bag/

APL position.

2. Drive gas hose disconnected or

leaking.

1. Place the Bag/APL-Vent selector

in the Vent position.

2. Reconnect drive gas hose or

check for leaks.

Alarms sound with-

out apparent cause

and cannot be

silenced.

1. Microprocessor failure.

1. Replace microcontrol board.

Ventilator will not turn

on when remote on/

off switch is turned

on and AC LED is on

1. 50 position cable, external cable

SIB to 7900

2. Remote on/off switch cable

3. Remote on/off switch

4. Power supply board

1. Ensure cable is plugged in prop-

erly at 7900 and SIB

2. Ensure cable is plugged in prop-

erly at switch and SIB

3. Replace switch

4. Replace power supply board

Settings do not meet

specifications.

1. Out of calibration.

1. Calibrate.

Erratic pressure

waveform

Slow exhalation pres-

sure release

1. Slight to moderate valve leakage

2. O-Ring Seal, Housing to Main

Manifold

3. Alignment of seat and seal after

assembly

4. Loose mounting screws

1. Check operation of drive gas

check Valve

2. Replace drive gas check valve

Summary of Contents for Aestiva 7900 SmartVent

Page 2: ...1503 0151 000 3 27 97 ...

Page 4: ...1503 0151 000 3 27 97 ...

Page 12: ...Notes viii 1503 0151 000 3 27 97 ...

Page 18: ...1 Introduction 1 6 1503 0151 000 5 26 0 Notes ...

Page 44: ...2 Theory of Operation 2 26 1503 0151 000 3 27 97 Notes ...

Page 46: ...3 Post Service Checkout 3 2 1503 0151 000 5 26 0 Notes ...