2-2. Operation of Control Parts

CLP-621 & CLP-631

2-24

(3-3) Tension Sensor F/R

The Tension Sensor F is used to detect the ribbon tension on the take-up side (front side)

as well as ribbon running. While, the Tension Sensor R is used to detect the ribbon tension

on the supply side (rear side) as well as the ribbon end. These sensors are

photointerrupters.

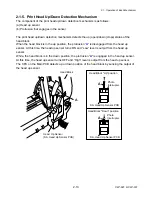

Tension Sensor F:

The Tension Sensor F is used to keep the ribbon tension on the take-up side constant.

When printing starts, ribbon is fed and take-up side ribbon slacks. Then, the claw of the

Ribbon Tension Shaft F SA comes off the photointerrupter on the Tension Sensor PCB and

the photointerrupter turns ON. Thus, pin 97 (SENS_A) of IC11 (Custom IC) goes "High"

level. Then, IC1 (CPU) drives the Ribbon Motor F to take up ribbon. As a result, ribbon

tightens and the claw is inserted into the photointerrupter. Thus, pin 97 (SENS_A) of IC11

(Custom IC) goes "Low" level. Then, IC1 (CPU) stops the Ribbon Motor F. During printing,

this cycle is repeated and constant ribbon tension is maintained.

The LED (D901) on the tension sensor lights when ribbon slacks (the claw of the Ribbon

Tension Shaft F SA comes off the photointerrupter and the photointerrupter turns ON). The

LED goes out when ribbon tightens.

If ribbon is not correctly fed during printing, the ON/OFF state of the photointerrupter on

the Tension Sensor F becomes improper. Thus, the CPU can detect a ribbon running error.

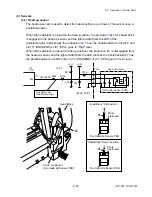

Tension Sensor R:

The Tension Sensor R is used to keep the ribbon tension on the supply side constant.

When printing starts, ribbon is fed and supply side ribbon tightens. Then, the claw of the

Ribbon Tension Shaft R SA is inserted into the photointerrupter on the Tension Sensor

PCB and the photointerrupter turns OFF. Thus, pin 98 (SENS_B) of IC11 (Custom IC) goes

"Low" level. Then, IC1 (CPU) drives the Ribbon Motor R to supply ribbon. As a result,

ribbon slacks and the claw comes off the photointerrupter. Thus, pin 98 (SENS_B) of IC11

(Custom IC) goes "High" level. Then, IC1 (CPU) stops the Ribbon Motor R. During printing,

this cycle is repeated and constant ribbon tension is maintained.

In the same way as for Tension Sensor F, the LED (D901) on the tension sensor lights

when ribbon slacks and goes out when ribbon tightens.

When ribbon runs out, the ON/OFF state of the photointerrupter on the Tension Sensor R

becomes unchangeable. Thus, the CPU can detect the ribbon end.

Summary of Contents for CLP-621

Page 1: ...Technical Manual CLP 621 CLP 631 Thermal Transfer Barcode Label Printer JM74961 00F 1 00E 0701...

Page 2: ...CLP 621 CLP 631 ii Copyright 2007 by CITIZEN SYSTEMS JAPAN CO LTD...

Page 4: ...CHAPTER 1 SPECIFICATIONS CLP 621 CLP 631...

Page 13: ...CHAPTER 2 OPERATING PRINCIPLES CLP 621 CLP 631...

Page 73: ...CHAPTER 3 DISASSEMBLY AND MAINTENANCE CLP 621 CLP 631...

Page 126: ...CLP 621 CLP 631 CHAPTER 4 TROUBLESHOOTING...

Page 138: ...CLP 621 CLP 631 CHAPTER 5 PARTS LISTS...

Page 166: ...Chapter 5 Parts Lists CLP 621 CLP 631 5 29 DRAWING NO 7 Control Panel Unit Rev 0 4 3 2 1 5...

Page 177: ...Chapter 5 Parts Lists CLP 621 CLP 631 5 40 DRAWING NO 10 Accessories Rev 0 3 2 4 1...

Page 179: ...CHAPTER 6 CIRCUIT DIAGRAMS CLP 621 CLP 631...

Page 208: ...APPENDICES CLP 621 CLP 631...

Page 212: ...B Mounting Diagrams AP 5 CLP 621 CLP 631 Main PCB Solder side...

Page 214: ...B Mounting Diagrams AP 7 CLP 621 CLP 631 B 3 Ribbon Main PCB Parts side Solder side...

Page 217: ......