starting the procedure. Perform each procedure in

sequence.

10. Recommendations are occasionally made to re-

fer service to a dealership or specialist. In these

cases, the work can be performed more economi-

cally by the specialist than by the home mechanic.

11. The term

replace

means to discard a defective

part and install a new part in its place.

Overhaul

means to remove, disassemble, inspect, measure,

repair and/or replace parts as required to recondi-

tion an assembly.

12. Some operations require the use of a hydraulic

press. If a press is not available, have these opera-

tions performed by a shop equipped with the neces-

sary equipment. Do not use makeshift equipment

that may damage the vehicle.

13. Repairs are much faster and easier if the vehicle

is clean before starting work. Degrease the vehicle

with a commercial degreaser; follow the directions

on the container for the best results. Clean all parts

with cleaning solvent as they are removed.

CAUTION

Do not direct high pressure water at

steering bearings, carburetor hoses,

wheel bearings, suspension and elec

trical components. The water will

force the grease out of the bearings

and possibly damage the seals.

14. If special tools are required, have them avail-

able before starting a procedure. When special tools

are required, they will be described at the beginning

of the procedure.

15. Make diagrams of similar-appearing parts. For

instance, crankcase bolts are often not the same

lengths. Do not rely on memory alone. It is possible

that carefully laid out parts will become disturbed,

making it difficult to reassemble the components

correctly without a diagram.

16. Make sure all shims and washers are reinstalled

in the same location and position.

17. Whenever a rotating part contacts a stationary

part, look for a shim or washer.

18. Use new gaskets if there is any doubt about the

condition of old ones.

19. If self-locking fasteners are used, replace them

with new ones. Do not reuse a self-locking fastener.

Also, do not install standard fasteners in place of

self-locking ones.

20. Use grease to hold small parts in place if they

tend to fall out during assembly. However, do not

apply grease to electrical or brake components.

Removing Frozen Fasteners

If a fastener cannot be removed, several methods

may be used to loosen it. First, apply penetrating oil

such as Liquid Wrench or WD-40. Apply it liber-

ally, and let it penetrate for 10-15 minutes. Rap the

fastener several times with a small hammer. Do not

hit it hard enough to cause damage. Reapply the

penetrating oil if necessary.

For frozen screws, apply penetrating oil as de-

scribed. Insert a screwdriver in the slot, and rap the

top of the screwdriver with a hammer. This loosens

the rust so the screw can be removed in the normal

way. If the screw head is too damaged to use this

method, grip the head with locking pliers and twist

the screw out.

Avoid applying heat unless specifically in-

structed, as it may melt, warp or remove the temper

from parts.

Removing Broken Fasteners

If the head breaks off a screw or bolt, several

methods are available for removing the remaining

portion. If a large portion of the remainder projects

out, try gripping it with locking pliers. If the pro-

jecting portion is too small, file it to fit a wrench or

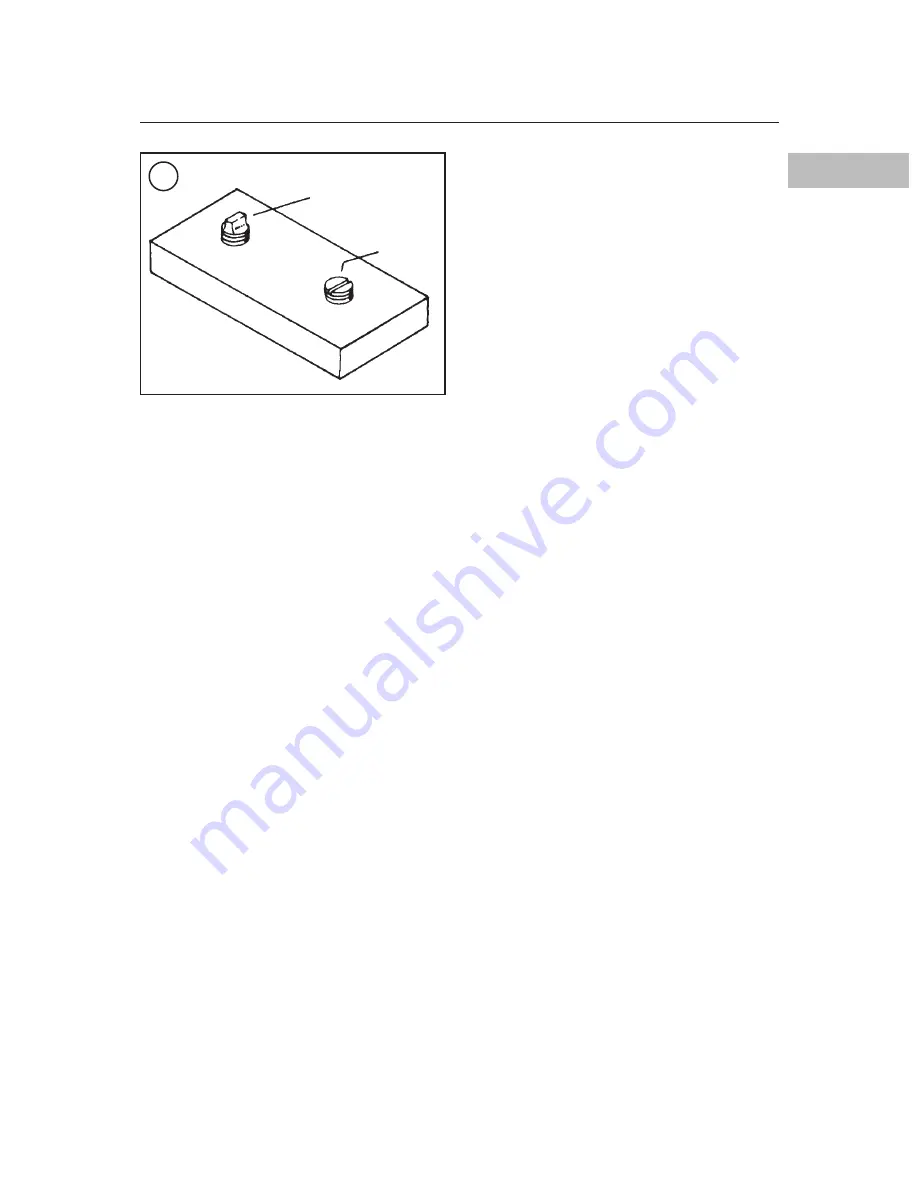

cut a slot in it to fit a screwdriver (

Figure 40

).

If the head breaks off flush, use a screw extractor.

To do this, center punch the remaining portion of

the screw or bolt. Drill a small hole in the screw and

tap the extractor into the hole. Back the screw out

with a wrench on the extractor (

Figure 41

).

GENERAL INFORMATION

21

1

40

Filed

Slotted