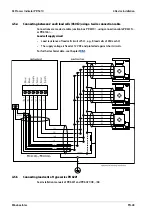

Configuration PR 5410

Printer configuration

- [Serial ports parameters]- [Printer]- [Built-

in RS-232]- [Param]:

-

[Protocol] to "RTS/CTS"

-

[Baudrate] to "9600"

-

[Bits] to "8"

-

[Parity] to "none"

-

[Stop bits] to "1"

-

[Output mode] to "Raw"

The printer must be set to "Line Mode" (the fac-

tory setting is Page Mode). Press the "FEED" key

to switch from one to the other.

The procedure can be found in the printer opera-

ting instructions.

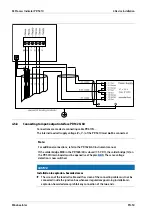

4.4.4.3

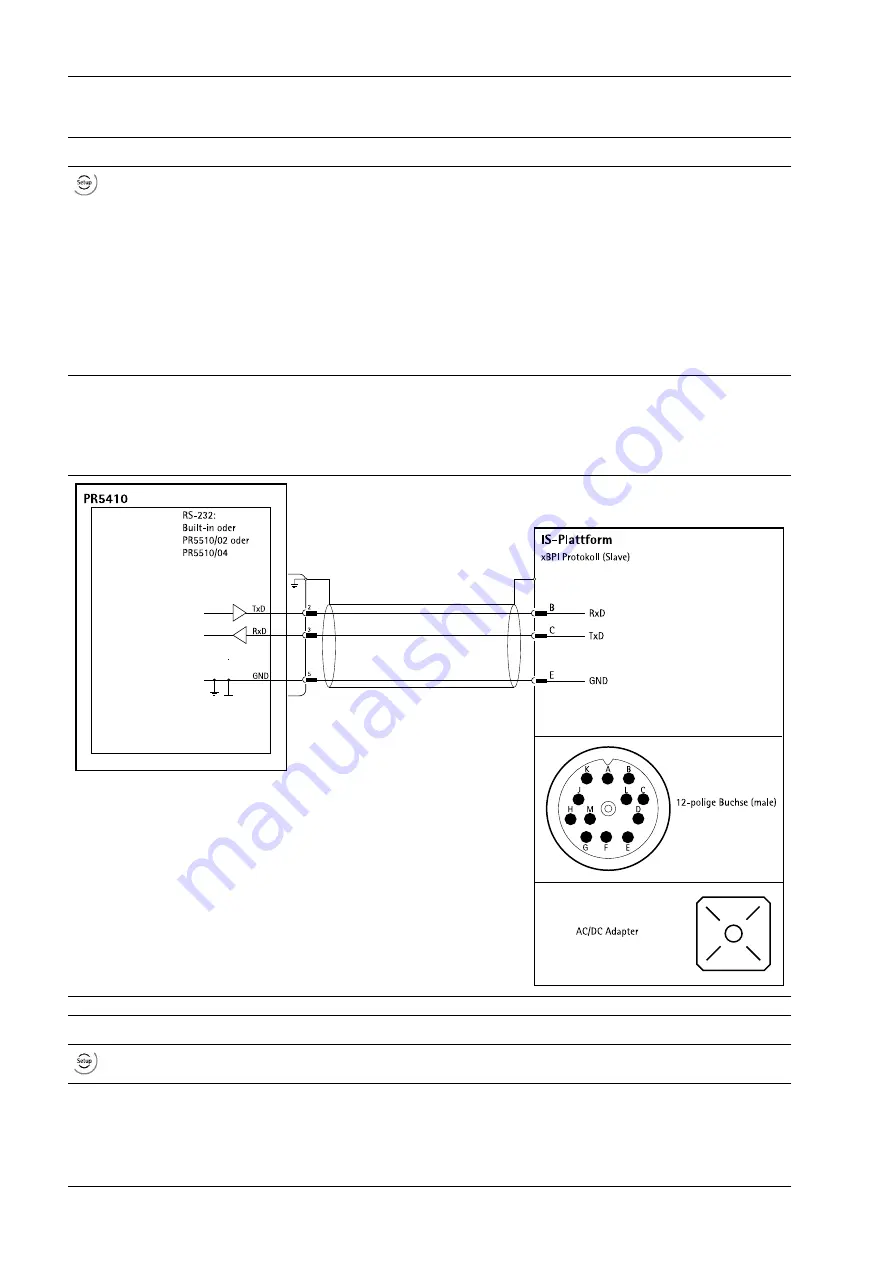

Connecting an IS platform

One IS platform scale with xBPI or SBI protocol can be connected via the internal RS-232

interface or the PR 5510/02 card or the PR 5510/04 card.

Configuration PR 5410

- [Serial ports parameters]- [xBPI port]- [Built-in RS-232]

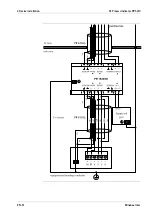

X3 Process Indicator PR 5410

4 Device installation

Minebea Intec

EN-38